| If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany' frameset |

|||||||||

|

51st Ordnance Group |

|||||||||

|

|

|||||||||

|

|||||||||

|

|

|||||||||

|

|||||||||

| 7848th Ordnance Maintenance Group History | |||||||||

| 1950 | |||||||||

| The rebuild shops are located at: |

|||||||||

| Was the 7845th Ord Gp redesignated as the 7848th Ord Gp in 1951? If so, why? | |||||||||

| 51st Ordnance Group History | |||||||||

51st Ordnance Group DUI 51st Ordnance Group DUI |

|||||||||

| 1945 - 1965 | |||||||||

| (Source: 51st Maintenance Battalion History. Compiled by the 51st Maint Bn in the early 1980s) | |||||||||

| The Headquarters

and Headquarters Company, 51st Ordnance Group was constituted on 20

December 1943 and activated 10 January 1944 at Palm Village, California.

The Group was transferred to Pomona Ordnance Base, California, and

again to Camp Polk, Louisiana. The Group was shipped overseas to England in the spring of 1944 and provided maintenance and supply support to the First Army from the time of the invasion until VE Day, the 8th of May 1945. After supporting Ninth Army from 11 May 1945 to 15 June 1945, it was placed under the operational control of Seventh Army. Cancelling a move to the Pacific Theater, the Group moved to Bremen and operated Ordnance Section, Port Bremen. Later, the Group was moved to Zirndorf, Germany, assuming control and supervision of Ordnance units and activities in the Eastern Military District until deactivation on 20 January 1947. On 26 March, 1947, it was redesignated as Headquarters and Headquarters Detachment 308th Ordnance Group and reactivated at Richmond, Indiana, with the Organic Reserves. On 1 August 1949, it was redesignated from a Detachment to a Company and a year later inactivated at Indianapolis, Indiana. The redesignation of the 7848th Ordnance Group, USAREUR to the 51st Ordnance Group on 15 January 1953 reactivated the Group to Esslingen, Germany, assuming control of all Ordnance Activities in the Army area. From 1954 to spring 1965, 51st Ordnance Group played an important role in carrying out 7th Army's preparedness mission. The Group, to provide better customer support moved during June 1954 to Coleman Barracks, Sandhofen, Germany. In 1959, Group Headquarters was moved to Funari Barracks, in Mannheim and later still, Pioneer Kaserne in Hauau, Germany. In August 1965, the Group was redesignated as Headquarters and Company "A", 51st Maintenance Battalion (Direct Support) and was relocated at Coleman Barracks, Mannheim, Germany. NOTE: The unit's subsequent history as the 51st Maintenance Battalion will be posted on the 51st Maint Bn Page. |

|||||||||

(Source: STARS & STRIPES, Nov 5, 1953) |

|||||||||

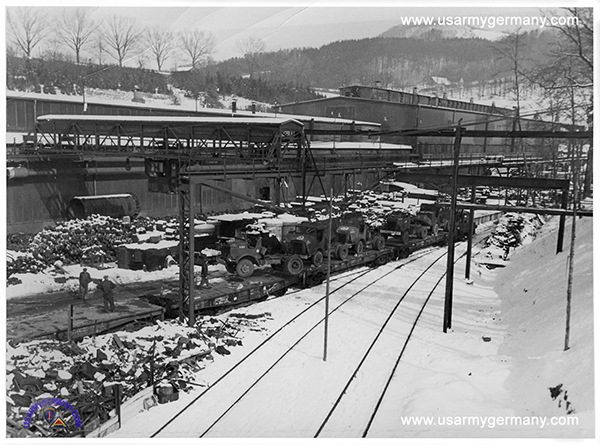

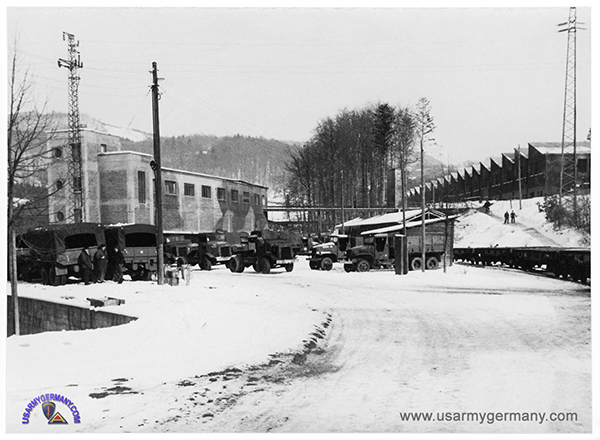

The decision to institute an ordnance rebuild program for the European Theater was made in 1945 when it became necessary to decide on what to do with the vast amount of supplies and equipment left in theater after WWII. Transporting them back to the US for rebuild and then sending them back to Europe for use by US troops would have been very costly. A large portion of the surplus equipment was sold in Europe, but sufficient supplies and equipment for rebuild were retained to fill estimated needs of US forces. Eight rebuild shops in Germany carry out the rebuild program. They fall under the command of the 51st Ordnance Group in Esslingen. (CO of the Gp is Col Humbert O. Nelli.) The eight depots are located at: They repair or rebuild, where economically feasible, equipment at a minimum cost. Items renovated under the ordnance rebuild program include tires (including tubes and other rubber products), assemblies for vehicles, small arms, fire-control devices, general-purpose vehicles (such as trucks, trailers, jeeps, sedans), combat vehicles, spare parts, tools and supplies. Since 1947, the rebuild program has saved the US Government and American taxpayers more than $1.1 billion dollars (1953 dollars). |

|||||||||

| If you have more

information on the history or organization of the 51st Ord Gp, please

contact me |

|||||||||

| (Source: STARS & STRIPES, May 11, 1954) | |||||||||

| The Army vehicle rebuild program, initiated nine years ago, is being signifiantly reduced as there are not many vintage WWII vehicles left that need to be rebuilt to give them new usefulness. Also, the trend is now towards contracting with civilian firms to perform rebuild work. The depots that used to perfom that task are being closed and derequisitioned (returned to the original German owners). By the end of the summer of 1954, more than half of the USAREUR ordnance rebuild installations that existed in 1951 will have been closed. The Army's commitments to the Mutual Defense Assistance Program (MDAP) to NATO countries led to more than 50,000 WWII vehicles and tons of supplies being completely rebuilt, processed and shipped by the USAREUR ordnance facilities.However, most of the WWII equipment has been replaced by newly developed items. All future rebuild requirements will be done under commercial contract. Some History In September 1951, 14 shops operated under the 7848th Ordnance Maintenance Group. Only four rebuild depots (Schwäbisch Gmünd, Ober-Ramstadt, Böblingen and Mainz) will remain in operation. The Mainz and Böblingen depots will be the center of the rebuild activity for USAREUR, USAFE and SFA. Also, only two supply depots will remain in Germany (Mannheim and Germersheim). Supply operations will be centered in Com Z. Closed installations: Planned closings: (1) Karlsfeld Depot is the largest Army-operated plant in the world. |

|||||||||

| Aalen Ordnance Maintenance Depot | |||||||||

| 1945 - 1954 | |||||||||

| (Source: STARS & STRIPES, Feb 21, 1954) | |||||||||

| The Aalen Ordnance Maintenance Depot, located in Wasseralfingen (east of Schwäbisch Gmünd), has ceased operations. The depot is part of the 51st Ord Gp. Originally, the depot started operations Dec 6, 1946 with the mission of rebuilding vehicles over 4-tons and Army busses. Eventually, over 1,400 German local nationals (over 70 percent of which were refugees) would be employed by the depot. In 1950, the depot was enlarged and designated as a depot in July of that year. The mission was expanded to include the rebuilding of major assemblies, axles, transmissions, steering gears, transfer cases, propeller shafts, winches, compressors, power takeoff units, and radiators for wheeled vehicles over 4-tons. Early in 1953, production at the plant shifted to support of MDAP (Mutual Defense Assistance Program) equipment. The depot began deactivation in July 1953. Recent CO's: Maj Phillip M. Biever (Nov 1950 - May 1953); Capt S.J.M. Winkowski (May 1953 - Oct 1953); Lt Col Fred L. Whittlesey Oct 1953 - present). |

|||||||||

|

|||||||||

| Neckarsulm Ordnance Rebuild Shop | |||||||||

Former Neckarsulm Ordnance Rebuild Plant (Metz Postkarten) |

|||||||||

| 1950 | |||||||||

| (Source: STARS & STRIPES, Aug 1, 1950) | |||||||||

| The Neckarsulm Ord Rebuild Shop was returned to its German owners, the NSU Werke. CO of the shop at the time of the turn over was Capt Frank L. Jewell. The rebuild shop had previously been operating under the Ordnance Automotive Center, commanded by Col J. E. McInerney. |

|||||||||

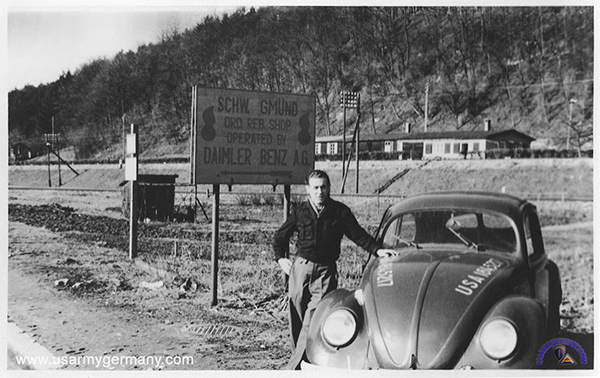

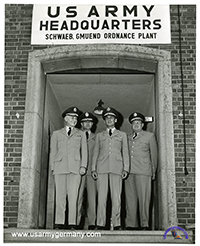

| Schwäbisch-Gmünd Ordnance Rebuild Shop | |||||||||

| 1947 | |||||||||

| (Source: Roland Knobloch, grandson of Karl Knobloch who worked at the Schwäbisch Gmünd Ordnance Rebuild Plant, 1947-1955) | |||||||||

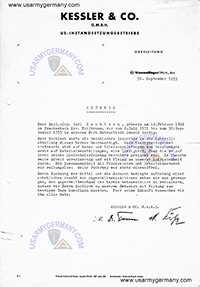

| I found your interesting website by chance. My grandfather, Karl Knobloch, worked as a mechanic, technical draftsman and later technical inspector at the Schwäbisch Gmünd Ordnance Rebuild Plant from 1947 to 1955. Initially, he was hired by Daimler-Benz which was the German contractor that operated the plant until 1950. In that year Kessler and Co. won the contract for operating the plant. He transferred to the Kessler company and worked for them until 1955 when the company had to make some reduction in force moves due to changes in their contract with the US Army. |

|||||||||

| 1959 | |||||||||

| (Source: Oren W. Bryant Collection, Army Heritage Center, Carlisle, PA) | |||||||||

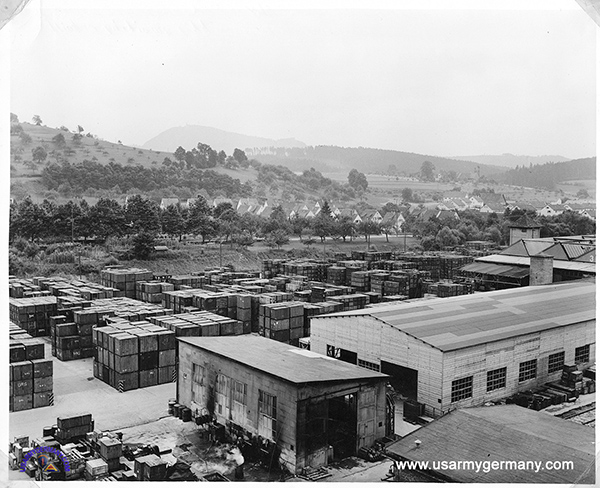

| Major Oren W. Bryant was assigned to the US Army Ordnance Plant Schwäbisch Gmünd (USAOPSG) effective October 11, 1958, to assume the duties of Officer-in-Charge, replacing Col Kirsten. The mission of the plant is the rebuilding of water-cooled engines and power train assemblies for light transport vehicles, heavy transport vehicles, and combat vehicles. The personnel comprising the USAOPSG is approximately 1,500 Local Wage Rate employees with five Ordnance Officers and two Enlisted Men. |

|||||||||

| (Source: STARS & STRIPES, August 26, 1959) | |||||||||

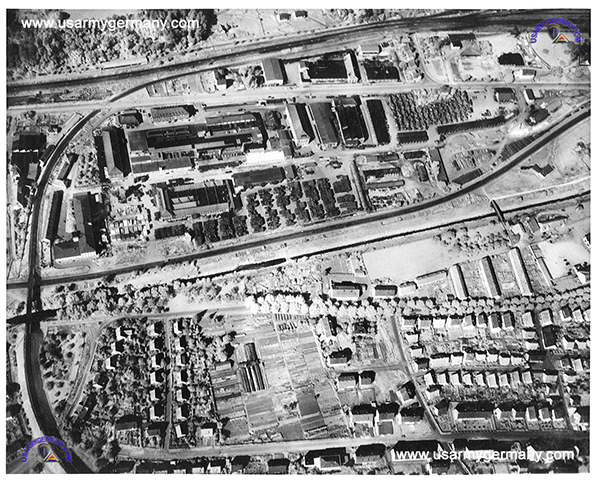

| The Schwäbisch-Gmünd Ord Plant is located on the western outskirts of the town of Schwaebisch-Gmuend, Germany, along Highway 20 (Webmaster note: today, that road is known as Highway 29. Typo by the author of the article or was it originally known as "20"?). The plant - comprising 17 brick and concrete buildings - is one of the largest engine and power-train rebuild factories in Europe, employing over 1,500 people and turning out close to 25,000 rebuilt and refurbished engines every year. Engines rebuilt at the plant include engines from American tanks, trucks, jeeps and armored personnel carriers; from French trucks, Danish tractor-trailers and German armored vehicles and half-tracks. These include 2½-ton Reo's; 5-ton Continental's used in tractor-trailers and wreckers; Fageol bus engines; White's for half-tracks and armored vehicles; Ford light tank engines; Cadillac models for heavy tanks; Waukeshas for self-propelled howitzers; and General Motors engines for trucks and armored personnel carriers. The production line begins with the cleaning and inspecting of all parts of an engine. As the engines move down the line precision machines are used to regrind, rebore or repair parts as needed. Further down the line, replating and rebalancing takes place. Engine blocks are also magnetically checked for flaws or cracks. At the end, the engines are reassembled and a final checkout is performed. (The rebuilt engines undergo 2½-hour tests at high speeds and in all gears.) If the engines pass the tests, they are painted, packed and sent back to work. |

|||||||||

Bill Bundard, Director of Quality Control, Schw. Gmünd Maint Plant, 1969 |

|||||||||

| (Source: email from LTC Douglas W. Richmond (Ret), son-in-law of William E. Bundard, Director of Quality Control) | |||||||||

|

|||||||||

Top - Bing's recent bird's eye view; Bottom - Marty receives an award in 1970 (mural on wall of Conference Room in background shows layout of the Maintenance Plant) |

|||||||||

| 1968 | |||||||||

| (Source: Email from Marty Krievs) | |||||||||

| I was surfing the net and stumbled on the historical web site containing some history on various maint units.

I was stationed at the US Army Maintenance Plant Schwaebisch Gmuend (USAMP-SG) from 1968-71 as Adjutant and Deputy Cdr. Still keep in touch with my Co's. The Schwaebisch Gmuend Maint Plant was located on the western outskirts of the town, on Highway 29 (Lorcher Strasse) as I recall. When I got there in Jan 1968 it was commanded by LTC Harry Skinker, followed by Maj Therman Greene and then LTC Jack Leach - all Ordnance Officers. To my best recollection Skinker was about the 4th or 5th CO from the Plant's inception (Under the name Maintenance Plant ). Col Leach would have a very good idea about how many commanders followed him before the place was shut down. The Depot's HQ building is the red brick with the brighter red top (and the 10 gables). As proof I submit photos taken inside the HQ conference room during my award's ceremony in Dec 1970. It shows a mural of the maintenance plant. In the picture (above) HQ is directly over LCT Jack Leach's head; The building I believe to house the "canteen" (kantine - cafeteria) is directly behind my head. |

|||||||||

|

|||||||||

| (Source: TASCOM Chronicle, May 22 1969) | |||||||||

|

|||||||||

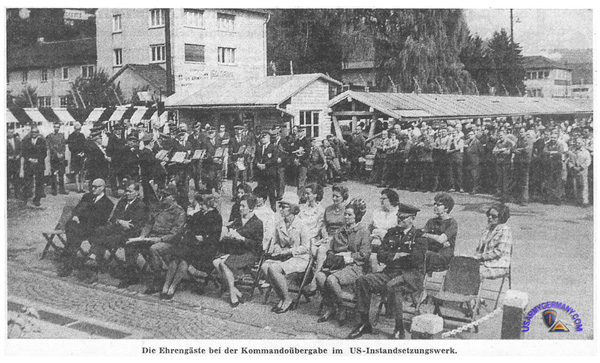

Change of Command ceremony at the Schwaebisch Gmuend Plant (Rems-Zeitung, Sept 1969) |

|||||||||

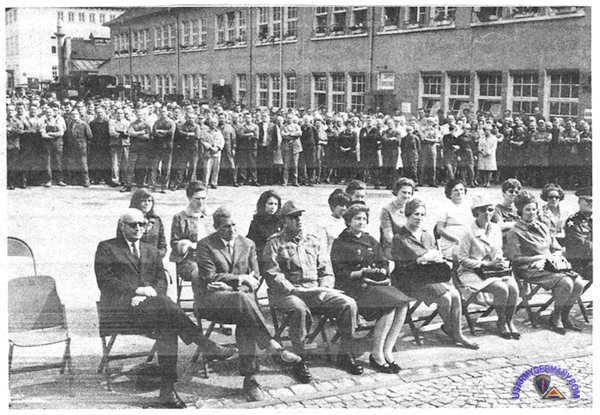

Another view of the Change of Command ceremony (Tagespost Schw. Gmünd, Sept 1969) |

|||||||||

| (Source: Therman R. Greene, former commander of the Schwaebisch Gmuend Maint Plant, 1969) | |||||||||

|

|||||||||

| Related Links: | |||||||||