|

54th

Area Support Group |

|||

|

|

|||

|

|||

|

|

|||

| History | |||

54th Area Support Group DI 54th Area Support Group DI |

|||

|

|

|||

|

|

|||

|

|

|||

| Reserve Storage Activity Rheinberg | |||

(Source: Traveler (Rheinberg MILCOM newspaper), June 1988) |

|||

| RSA Rheinberg is first of a series |

|||

| On April 29, the 54th Area Support Group saw the official opening of its first in a series of Theater War Reserve sites to be established in NORTHAG when Capt. Michael R. Alvarez assumed command of the Reserve Storage Activity (RSA), Rheinberg. Construction of RSA Rheinberg at the Vanguard Kaserne (formerly known as the Reichel Complex) is due to begin in June 1989. Deployment of equipment to the RSA Rheinberg began during the Redeployment Phase of REFORGER 87. Since then, a small crew from the 8017th Civilian Service Group (CSG) has warehoused and cared for the equipment in this interim storage facility. Upon its completion, expected in December 1990, RSA Rheinberg will be the newest RSA in Europe and the first in northern Germany. |

|||

|

|

|||

| 6931st Civilian Support Center | |||

6931st

CSC Patch

(courtesy Siegbert Mann) 6931st

CSC Patch

(courtesy Siegbert Mann) |

|||

| 1986 | |||

|

(Source:

Traveler (Rheinberg MILCOM newspaper), December 1986)

|

|||

| Grevenbroich

units increase their workload By Khalid Rashid Traveler staff |

|||

| The Civilian

Support Organization (CSO) here will, within the year, become a self

sufficient supply and maintenance organization, fulfilling a plan

that was developed back in 1981. According to Capt. Freddie Watkins, Material Plan and Operations Officer for the 54th Area Support Group, Rheinberg will house a CSO that will provide supply and maintenance support to the entire military community. "The 6931st Civilian Support Center (CSC) will take over current maintenance support provided by the 51st Maintenance Battalion in Mannheim," said Watkins, "and all supply support that at this time comes from the Supply Support Activity (SSA), Schinnen, the Netherlands." "The CSC will include separate guard, maintenance and supply outfits and these will help to cut down on traveling time for all RMC units that require any maintenance or supply support," he added. The 6931st CSC, equivalent to a battalion, controls the administration and operations of three Groups temporarily located at Grevenbroich. The 4002nd Civilian Support Group (CSG) is a guard unit; the 8900th is responsible for maintenance and the 8017th specializes in supply. Eventually all the units will be located at Rheinberg. "The CSG's took over the site at Grevenbroich earlier this year and have managed to set up limited operations while they await more equipment and personnel," said Lt. Col. Jordan H. May, Director of Materiel for the 54th ASG. "The 6931st is making a gradual transformation toward reaching a fully operational role." In December 1981 when the gradual build up began, only one CSC representative was working at the Reichel Building. According to ZB 7 Maxi Heyer, she was here as a point of contact for 21st Support Command and to watch over the build up of the Center. "Now the 6931st CSC has almost 200 positions filled and is slowly taking over responsibility for guard, supply and maintenance operations in the RMC," stated Heyer. "With the ordering and storage of repair parts and limited maintenance of weapons and vehicles within the Rheinberg Military Community, the CSC is slowly beginning to take on more and more responsibility," said ZB 9 Kurt Braunberger, Acting Superintendant for the 6931st and Commander of the 8900th CSG. According to Watkins the 6931st CSC will become fully mission capable by April 1987. "Vehicle repair, repair parts supply, maintenance of desks and office equipment will all be handled by the outfits at Grevenbroich," he added. The Civilian Support Organization personnel are really local nationals in uniform. "We are hired like local nationals and like them are entitled to a Works Council," stated the Acting Superintendent. "But unlike them we have to undergo a two-phase initial training course either here or in Kaiserslautern immediately upon hire." Phase one of the training involves first aid, physical security, labor and employment regulations, and emergency procedures. Meanwhile the second phase concentrates on basic survival skills. This includes a compulsory range shoot for males (females can attend if they wish to) and instruction in self-defense. Upon completion of initial training more specialized on-the-job training is provided at an established Supply, Maintenance or Guard Group in the Federal Republic of Germany. "This training is designed to get the personnel ready to fit into a given mission role in support of the Civilian Support Organization and the U.S. Army," said May. Polish nationals, Lithuanians, Latvians, Germans, Austrians and prisoners of war were used to make up the very first "Labour Service" guard unit in May 1945. According to Lt. Col. May, the Civilian Support Organization has changed and come a long way from those early days after World War II, especially here in the RMC. |

|||

| Jülich Maintenance Plant (German Army) | |||

German Army vehicles at the Jülich Maintenance Plant (Aachener Zeitung, Aug 6, 2013) (Plant building in the background dates back almost a 100 years ago when the plant was originally constructed as a railway maintenance and repair facility.) |

|||

|

(Source:

Traveler (Rheinberg MILCOM newspaper), August 1987)

|

|||

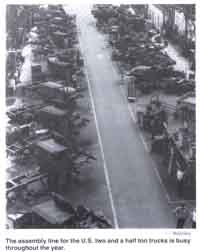

| Old U.S. trucks

get face-lift in Jülich By Khalid Rashid Traveler staff |

|||

| Receiving approximately

200 M35 A1 series two-and-a-half ton trucks for repair yearly and

transforming the 12 to 20 year old trucks to look almost new is a

mean feat. The state of the trucks when they arrive for repair leaves

no doubt why almost one-third of the manhours at this repair facility

are credited to U.S. vehicle repairs. The German Army Maintenance Plant at Jülich ( The U.S. truck maintenance facility falls under the RMC's Directorate of Materiel, and has 67 local employees, plus Prenovost, two quality assurance inspectors and two supply specialists who handle the repair operations of the trucks. "The Bundeswehr allows 50 percent of the facilities at Jülich to be used for U.S. vehicle repair," said Prenovost. "That is because they only repair 20 percent of their wheeled-vehicles here. The other 80 percent are done commercially." The generous use of space and equipment gives the U.S. vehicle repair an opportunity to provide maintenance up to and including some general support level maintenance. |

|||

| The Supply Support

Activity Rheinberg provides the Jülich facility with supplies,

and handles the exchange of engines and transmissions. Jülich's U.S. truck repair facility has worked on vehicles from all over Germany. Recently, trucks from the Berlin Brigade were delivered under the USAREUR Swap Out Program to Jülich. This program allows units to swap old vehicles for newer ones, and gets the older vehicles overhauled. "Vehicles have arrived here from Germersheim, Mannheim and mainly Northern Germany," said Prenovost. According to Prenovost, the truck repair facility will be seeing a change for the better soon when the paint shop starts using two pattern camouflage paint on the two-and-a-half ton trucks. This paint is chemical resistant and the Jülich repair facility will be one of the few facilities using it. "This facility will get better and will continue to repair trucks even after my retirement," he added. |

|||

|

|

|||

|

|

|||

| Related

Links |

|||