| If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany' frameset |

|||||||||||||||||||||

|

Fürth Medical Depot |

|||||||||||||||||||||

|

|

|||||||||||||||||||||

|

|||||||||||||||||||||

|

|

|||||||||||||||||||||

| History | |||||||||||||||||||||

| 1945 - 1951 | |||||||||||||||||||||

| (Source: Chapter XI, Redeployment and Occupation from the Medical Supply in World War II, Office of Medical History, Office of the Surgeon General) | |||||||||||||||||||||

|

|||||||||||||||||||||

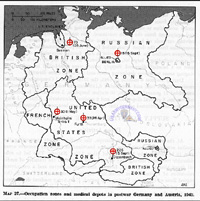

The Bremen Medical Depot, operated by the 70th Medical Base Depot Company at a site near the port of Bremerhaven, served not only as a filler depot for the Bremen Enclave but also as a base depot for inshipments from both the United Kingdom and the Zone of Interior. Although the depot was small, the troop strength supported directly by it was also small. Moreover, access routes into the depot were excellent. It was decided that, by augmenting the depot’s ramp facilities to expedite off and on loading, the depot could continue to serve as a base depot to handle the receiving and shipping functions in support of the occupation forces. The Berlin Medical Depot, operated by a detachment of the 15th Medical Depot Company, was established in the Berlin Enclave to initially support approximately 50,000 troops. Its site was near the grounds of the 279th Station Hospital located in a small enclosed tennis court. Due to the reduced strength of the Enclave, the depot was shortly inactivated and became an issue point under the 279th Station Hospital. United States forces in Austria received their medical supply support from the 226th Medical Supply Detachment located in Glasenbach, Austria. This detachment, in turn, requisitioned its requirements from the Furth Medical Depot in the U.S. Occupied Zone of Germany.5 Medical Supply Division, Theater Chief Surgeon’s Office Although the medical depot system in the U.S. Occupied Zone of Germany and Austria was under major subordinate commanders, it was technically supervised by the Supply Division, Theater Chief Surgeon’s Office, TSFET (Theater Service Forces, European Theater). From the cessation of hostilities through 31 December 1945, there was a progressive transfer of responsibilities from the TSFET (REAR) office located in Versailles, France, to the TSFET (MAIN) office in Frankfurt, Germany. As of 1 October 1945, Col. Robert L. Black, MSC, was chief of the Supply Division with station in Versailles, and Lt. Col. Louis F. Hubener, MC, Deputy Chief, Supply Division, was acting chief of the Supply Division in Frankfurt. The move of the Supply Division from TSFET (REAR) in Versailles to TSFET (MAIN) in Frankfurt was completed by 7 November 1945. During the last 3 months of 1945, the Supply Division efforts were directed toward the buildup of (1) a minimum 60-day maintenance level in all medical depots in Germany and (2) a reserve stockpile in Germany sufficient to maintain the occupation forces until 30 June 1949. To accomplish this objective, a comprehensive study was made first of issues in Germany, and then, replacement factors were revised upward on all items on which issues in Germany were higher per 1,000 men per month than the overall theater issues. Likewise, downward revisions were made where indicated. Based upon the revised replacement factors, 60-day maintenance levels and 30 June 1949 levels were computed by using the factors in combination with estimated troop strength for the periods involved. To maintain a minimum 60-day supply of each item stocked in the theater, monthly maintenance requisitions were placed on the Zone of Interior. Requisitions were based on a 180-day reorder point to allow for a 120-day shipping time. Incoming shipments on such requisitions were received through the port of Bremerhaven by the Bremen Medical Depot, and from this depot, supplies were transferred as needed to other filler depots in Germany. Each medical depot in Germany was authorized a proportionate part of the 60-day maintenance level, computed on the percentage of total troops served. Based upon information contained in the theater’s consolidated stock status report, transfers among the various depots were effected to insure a minimum 60-day stock of each item, except key depot items, in each filler depot. Key depot items were books and blank forms, stocked only by the Furth Medical Depot, and teeth, stocked only by the Weinheim Medical Depot. The buildup of the 30 June 1949 level from stocks already in the theater was stressed during the last 3 months of 1945. Approximately 10,000 long tons of medical supplies from depots in liberated countries and the United Kingdom were moved into Germany. Arrangements were made also to bring to Germany the so-called luxury items for installation in the larger, permanent medical installations in Germany. Many of these items—for example, large fixed X-ray machines—had been brought to the Continent only in small numbers during combat operations because of the special handling required. The hospitals established on a semi-Zone-of-Interior standard to support occupation forces in Germany brought about a heavy demand for these items. During the latter part of 1945, the International Business Machines Section of the Stock Control Branch was moved from Paris to Frankfurt. As a result of the damage incurred to the equipment in transit and the difficulties encountered in installing it at the new location, the first consolidated stock status report was not prepared until the middle of December 1945. Among the problems encountered was the understandable unwillingness of French personnel to move to occupied Germany. It was, therefore, necessary to recruit German nationals with electrical accounting machine experience to staff the new section in Frankfurt.6 Medical Maintenance and Repair With the reduction of medical maintenance and rebuild requirements in liberated areas, transfer was made of necessary equipment and repair parts to the Furth and Weinheim Medical Depots in the. occupied zone. The large maintenance shop, located at Medical Depot M-407 in Paris, discontinued operations at the end of November and moved to Germany. At both Weinheim and Furth, the maintenance shops were staffed not only with U.S. military and civilian personnel, but also with German civilians and prisoners of war.7 Optical Program The Base Optical Shop in Paris, with small portable units operated at various medical depots, continued in operation during the entire period. Bifocal corrections were accomplished by French contract and proved very satisfactory. To accomplish optical requirements in the occupied zone, small units were established at the Furth and Weinheim Medical Depots as well as a portable unit in Berlin to care for emergency cases.8 CIVIL AFFAIRS In addition to the task of establishing a medical supply system to support the U.S. forces in occupied Germany, the Theater Chief Surgeon was faced with an equally difficult task of providing essential medical supplies to displaced persons camps, prisoner-of-war enclosures, and the German civilian economy. A Civil Affairs Section in the Supply Division had the mission of coordinating and supervising the execution of this mission. Medical supplies for the U.S. Military Government mission in Germany came from two sources: (1) Civil Affairs stocks brought from the Zone of Interior and the United Kingdom, and (2) captured enemy medical materiel. In the beginning, all civil affairs stock was stored in Medical Depot M-412 at Reims. This stock included approximately 175 basic medical items, including British obstetric kits, British CAD (Civil Affairs Drug) units, and antityphus supplies. Military government authorities decided that 50 of the basic medical items should be transferred to the occupied zone and stocked in occupation depots for military government use in that area. These supplies were issued only upon approved request of military government authorities. Over 30,000 tons of captured medical supplies and equipment were consolidated in the U.S. Occupied Zone of Germany into nine major supply dumps with locations at Heilbronn, Gauting, Ihringshausen, Neuhof, Straubing, Furth, Heidingsfeld, Treuen, and Bad Mergentheim. This number was reduced to the first six named locations to provide three dumps in each of the two military districts. A minimum of U.S. military personnel operated each dump, and former German civilian supply personnel were utilized as the main source of labor (fig. 98). Col. Earle D. Quinnell, MC, Director, Medical Department Equipment Laboratory, Carlisle Barracks, Pa., made a special trip to France in early 1945 to inspect captured German field equipment and to arrange to have it sent back to the Zone of Interior for further study. |

|||||||||||||||||||||

| (Source: Author's private collection) | |||||||||||||||||||||

|

|||||||||||||||||||||

|

|||||||||||||||||||||

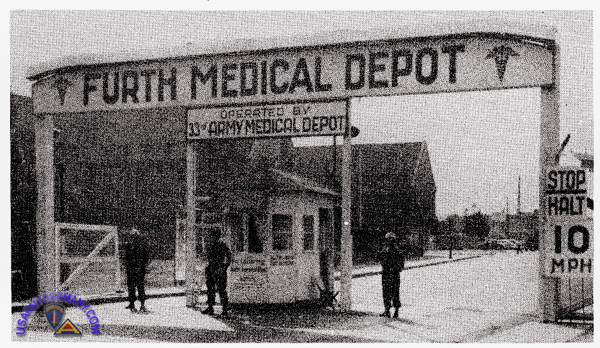

Grainy photo, interesting picture: Main gate, 1951 |

|||||||||||||||||||||

| 1951 | |||||||||||||||||||||

| (Source: EUCOM Medical Bulletin, Sept 1951) | |||||||||||||||||||||

| Constituted in the Army of the United States, 1 Sept, 1943. Activated at Camp Carson, Colorado, 5 Oct. 1943. Participated in the Normandy, Northern France, Rhineland, Ardennes-Alsace, and Central Europe campaigns of World War II. Awarded a silver band for each campaign. Presented a meritorious unit streamer, embroidered with "European Theater," by the Headquarters of the Third U.S. Army on 20 Sept, 1945. Allotted to the Regular Army, 6 Dec. 1950.

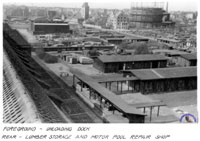

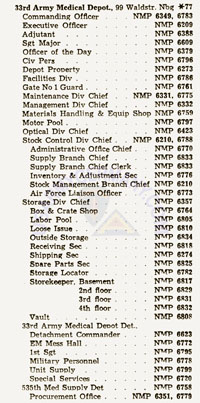

That's the history in brief, not of some infantry, tank, or paratroop unit, but of the 33d Army Medical Depot, a Medical Service installation. Since the cessation of hostilities, the 33d Army Medical Depot has operated the Furth Medical Depot on the outskirts of Nurnberg, Germany. There, its stated mission is (a) to receive medical supplies from the continental United States and other countries designated by the EUCOM Chief Surgeon, (b) to furnish complete medical supply service to all medical installations in the European Command and to other agencies designated by the EUCOM Chief Surgeon, (c) to receive unserviceable equipment that could be repaired and excess standard U.S. Army medical equipment, (d) to operate an optical shop and a depot medical maintenance and repair shop, and (e) to operate a surplus property section for medical supplies declared surplus by the EUCOM Chief Surgeon. The increase in work load is more clearly seen by studying the monthly average of line items received by the depot for processing. (A line item is one item on a requisition, whether for a package of dental burro weighing less than an ounce, or for a 40-cubic-foot mobile disinfector.) A total of 19,623 line items were received for processing during the average month in 1949, 25,423 in 1950, 28,498 in 1951, and 39,296 line items were received in June, 1951, the last month of available statistics, In short, the line item work load for the first half of 1951 was 45.2 percent more than in the last half of 1949. Although operating in an expanding economy, the depot emphasized better service at lower cost. Employees' suggestions were actively encouraged. Better ways of receiving, storing, and shipping supplies were sought. The cost of avoidable accidents was lowered through improved safety techniques. The American taxpayer's dollar is also guarded by the medical maintenance and repair shop. During the past year, the shop repaired Medical Service equipment valued at nearly $3,000,000. Shop expenses amounted to $114,542. The actual savings, then, was $2,713,685 or 2,369 percent! The maintenance shop built recently a self-sustaining X-ray van. It is now used throughout the U.S. zone of Germany and can turn out as many as 500 X-rays a day. The closed van-type trailer contains a 200-milliampere X-ray unit with a photo-roentgen unit, a complete darkroom for processing film, and drying bins and storage facilities. A 250-gallon tank furnishes water required in the developing process. Special air intakes heat the interior and dry the film. In addition to on-the-job training is specific occupational specialties, personnel studied such subjects as the basic duties of a soldier, military justice, character guidance, safety procedures. They took physical training and participated in field training. Field training and soldier's glasses are not necessarily compatible: the more rigorous the training, the higher the breakage as personnel in the optical shop know well. Lest year they manufactured 15,240 spectacles, mostly the sturdy steel-rimmed kind. Plastic frames, however, were supplied to soldiers with certain skin conditions. The 818 pairs of bifocals manufactured last year required special care in grinding and polishing the rough and semi-finished Krptock blanks. Most prescriptions, however, could be filled by lens already stocked in various corrections. This cut down on the time-consuming tasks of grinding and polishing and allowed the optical shop to better its service. The constant aim of supplying the best service at the lowest cost was recognized last year when the depot was awarded the "Best Unit" plaque in the EUCOM supply economy competition. All medical units under the direct command of the EUCOM Chief Surgeon competed for the plaque. Supply men say that one of the most important aspects of good supply procedure is careful computation, and perhaps that is why one of the depot men has applied an adding machine to the building of a softball diamond. He figured that depot personnel hauled in 700 yards of dirt, tamped down 37 tons of red brick dust, and planted 180 pounds of grass seed to complete a diamond for tournament play. Incidentally, the depot was last year's

softball champions in the Furth area and garnered second place in the Nurnberg Post finals. |

|||||||||||||||||||||

| If you have more information on the history or organization of the Fürth Medical Depot, please contact me |

|||||||||||||||||||||

| 33rd Medical Company | |||||||||||||||||||||

| 19.. - 19.. | |||||||||||||||||||||

| (Source: Nurnberg Military Post Telephone Directory, 15 April 1951) | |||||||||||||||||||||

|

|

|||||||||||||||||||||

| Related Links: |