If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany'

frameset |

US

Army Petroleum Distribution Comd, Europe

Communications Zone

Looking for more information from military/civilian

personnel assigned to or associated with the U.S. Army

in Germany from 1945 to 1989. If you have any

stories or thoughts on the subject, please contact me . .

|

|

|

|

|

|

|

US Army Petroleum Distribution Comd, Europe |

|

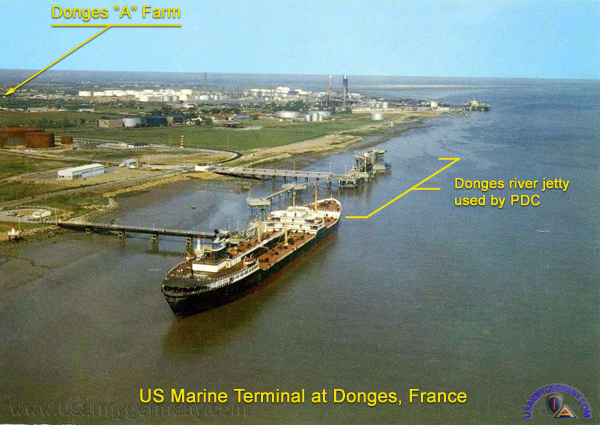

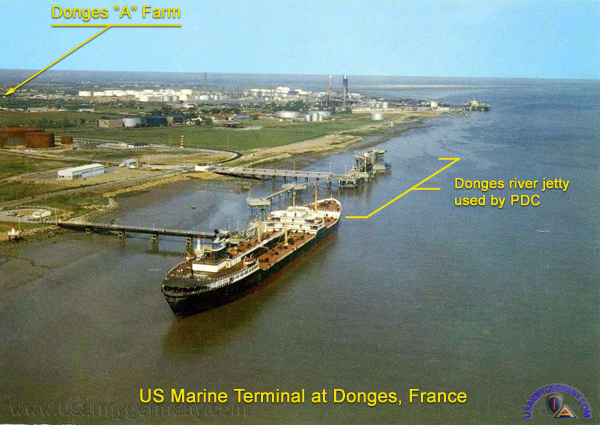

US marine terminal at Donges (a) |

|

(a) Webmaster note: I am fairly certain information is accurate - would appreciate final confirmation from anyone who served with the PDC. |

|

|

|

(Source:

FRELOC After Action Report, 1966-67, Vol II.)

|

Exhibit

17

Exhibit

17 |

|

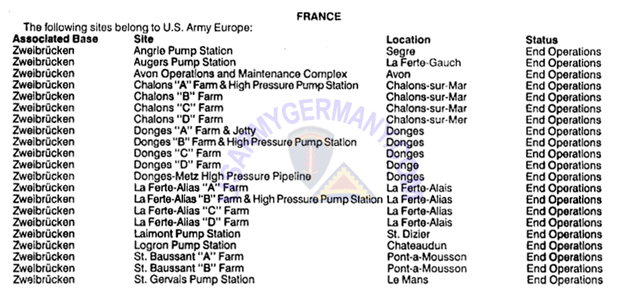

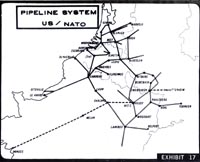

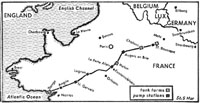

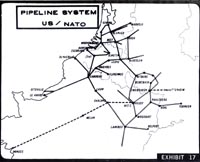

Prior

to FRELOC there were three separate, yet interconnected

and interdependent, pipeline and tank farm systems in

Central Europe. (See Exhibit 17)

|

|

Two were US systems, financed, constructed, controlled, and either fully or partially operated by the United States. (A French quasi-governmental agency, TRAPIL, operated the pipeline and pump stations in France). The other, the Central Europe Pipeline Systems (CEPS), was constructed under NATO infrastructure programs and was operated, managed, and maintained jointly by the eight nations whose forces were served by it; the Host Nations of Belgium, France, Germany, Luxembourg, Netherlands, and user nations of Canada, United Kingdom, United States. Control of the CEPS was (and still is - at time of report) exercised through two corporate type bodies in which each of the eight nations are represented: the Central Europe Pipeline Policy Committee (CEPPC) for financial and political matters and the Central Europe Pipeline Office (CEPO) for operational and military readiness aspects. Centralized planning control over the CEPS is exercised through a NATO body called the Central Europe Operating Agency (CEOA).

The two US Pipeline Systems were the Donges-Metz System in France and the Zweibruecken-Huttenheim System in Germany. The 391-mile Donges-Metz line between the receiving port of Donges and St. Baussant near Metz, France contains over 5. 7 million bbls of tankage and has a rated throughput of about 76, 000 bbls per day.

The system in Germany is much smaller; 55 miles long between a point near Zweibruecken to Huttenheim, east of the Rhine, with 342,000 bbls of tankage. The two US systems are connected by the CEPS between Metz, France and Zweibruecken, Germany. Besides linking the US systems, the CEPS contains over 3,200 miles of pipeline, 7,200,000 bbls of tankage, and port unloading facilities at Le Havre, Marseilles, Dunkerque, Hansweert, Zeebrugge, Pernis (Rotterdam), and Antwerp. |

|

|

|

1992 |

(Source: STARS & STRIPES, Aug 14, 1992) |

The drawdown in Europe provided some insight into the 390-mile Donges-Metz pipeline system that ran from St.-Nazaire on the French coast to the French-German border near Saarbrücken. This US-owned, French-operated pipeline was part of the larger Central European Pipeline System (CEPS).

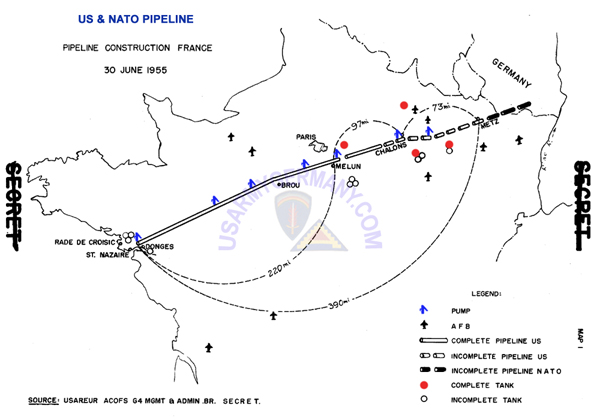

The list below shows facilities that served as pump stations or maintenance complexes along the pipeline system that are all scheduled for closure. (The "farms" listed here refer to clusters of POL storage tanks .... tank farms.) |

|

|

|

|

|

| 509th Quartermaster Company |

|

1957 |

(Source: Email from John Woods) |

1ST TOUR OF DUTY IN GERMANY

1957-1960: Arrived in Bremerhaven, Germany in June of 1957 aboard the USNS Buckner with assignment to the 509th Quartermaster Company with headquarters in Kapaun Barracks, Kaiserslautern. The 509th was a Petroleum Depot Company under the Petroleum Distribution Command in Fontainebleau and the Petroleum Distribution Command, Zweibrucken (Webmaster note: should be Zweibruecken Terminal District?) with locations in K-Town and in a small town outside of Pirmasens called Ruppertsweiler.

I was assigned to the detachment in Pirmasens and was billeted with the 522nd Quartermaster Company, which operated Class I facilities out of the numerous caves surrounding the city of Pirmasens.

Our days started with a truck ride of about 30K’s to Ruppertsweiler where we maintained Class III Petroleum Supplies stored in 5 gallon cans and 55 gallon drums in outside storage locations. We worked from a small office building just inside the gate with a mixture of military and civilian labor. It is my understanding that the facility was turned into a CENTAG Rear Area Command sometime in the 60”s.

Our NCOIC was SFC William Denny and Asst. NCOIC, SFC Thomas Neckwinder In March of 1959 we were attached to the 225th Station Hospital Muenchweiler for rations and quarters. During my tour with the 509th it was commanded by Capt. Michael Plummer and later by Capt. John Skinner with Col. Robert Dill as Commander of the Petroleum Distribution Command, Zweibrucken.

Two things that stand out in my mind about this tour are the jeeps mounted with 50 Cal. machine guns delivering the pay to headquarters on May Day and traveling to the surrounding towns and observing the World War II property damage. |

|

|

|

1962 |

(Source: STARS & STRIPES, July 9, 1962) |

The 509th Quartermaster Company (Petroleum Depot), Kaiserslautern, provides the following services:

delivery of bulk and package products (using cargo trucks and 1,200-gallon and 5,000-gallon tankers); delivery of bulk and package products (using cargo trucks and 1,200-gallon and 5,000-gallon tankers);

loading and unloading of petroleum barges on the Rhine River; loading and unloading of petroleum barges on the Rhine River;

distribution of gasoline from the American-owned pipeline through France; distribution of gasoline from the American-owned pipeline through France;

renovation of drums and cans. renovation of drums and cans.

The unit receives (monthly) an average of 20 million gallons of petroleum products - shipped through tank trucks; railroad tank cars and river barges.

The 509th maintains a strategic reserve of approximately 30,000 tons of POL products.

The unit is assigned to the Zweibruecken Terminal District, which is part of the Petroleum Distribution Command at Fontainebleau in France.

The Sonderheim (Tank Farm) (near Bellheim) is one of the facilities operated by the 509th. |

|

|

|

|

| 543rd Quartermaster Company |

|

543rd Engineer Company, PDC, sign

at Melun Tank Farm (James Roberts) |

|

(Source: Fueling the Front Lines: Army Pipeline Units - Part II, by Thomas J. Petty, ENGINEER, Jan-Mar 2008) |

From the mid-1950s to the end of the 1960s, there were only three pipeline companies in the US Army:

697th Engr Co (Pipeline), CONUS and later Thailand 697th Engr Co (Pipeline), CONUS and later Thailand

515th Engr Co (Pipeline), CONUS 515th Engr Co (Pipeline), CONUS

543rd Entgr Co (Pipeline), Communications Zone, France 543rd Entgr Co (Pipeline), Communications Zone, France

The 543d Engineer Company (Pipeline) was stationed in France and was deactivated there in 1970.

Click here to read about the pipeline school that was run by the 543rd at Chinon Engineer Depot.

|

|

|

|

| Donges-Metz Pipeline System |

|

|

|

1955 |

(Source: STARS & STRIPES, February 19, 1955) |

First Sector Completed

The Joint Construction Agency in France reported that the first sector of the US Donges-Metz pipeline has been completed. The sector, from Donges (near St. Nazaire) to Melun (about 20 miles southeast of Paris, is approxinately 220 miles in length and comprises about 60 percent of the total length of the US pipeline.

In addition to the pipeline, the construction project includes tank farms, branch stations and pumping stations. This project is the most expensive item of the military construction program in France.

Work on the second sector, the stretch between Melun and Chalons, is already underway. The third and final sector will extend from Chalons to Metz.

|

|

|

1967 |

(Source: STARS & STRIPES, November 23, 1967) |

France Pullout

One of the most critical aspects of the move out of France (FRELOC) was the fate of the 400-mile US petroleum pipeline. The line runs from Donges on the French west coast to Metz and was built nine years ago at a cost of $57 million to the Unites States. The system has a capacity of 6.25 million barrels.

A contract has been negotiated with a French company known as TRAPIL to secure and operate the four terminals (Donges, Melun, Chalons and Metz). Tankage at Chalons and Melun has been mothballed.

To offset the loss of petroleum storage facilities in France, the US has leased tankage for 3.7 million barrels in Germany and the Benelux countires. Construction of additional tankage in Germany is under consideration.

|

|

|

(Source: Resource.org) |

Click here to view LOC Form 101, the agreement (with modifications) between the US and French governments to have TRAPIL (French contractor) operate and maintain the US-owned pipeline between Donges and Metz, France.

Document contains some very interesting details (from the 1950s and early 1960s) about the structure and operation of the US-owned pipeline. |

|

|

|

|

| PDC Terminal Districts |

|

| Donges Terminal District |

|

Texaco fleet tanker at the Donges jetty (Adolf Minaschek)

|

|

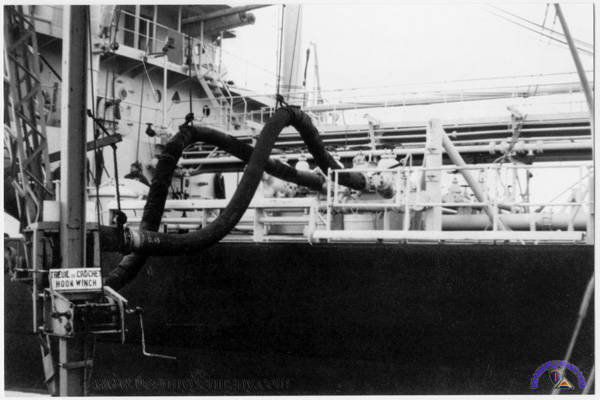

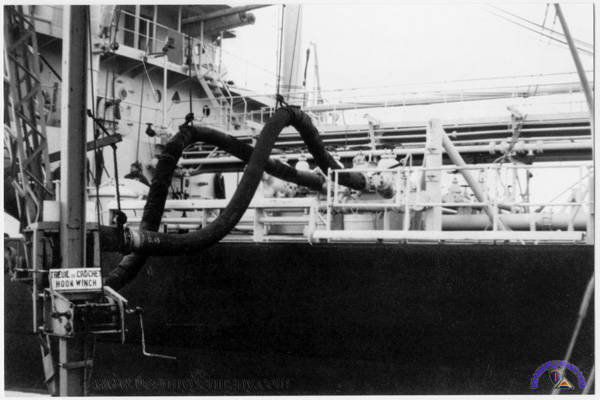

All hooked up, ship-to-shore pumping commences (Adolf Minaschek)

|

|

Closer view of flex hoses hooked up to the tanker's manifold (Adolf Minaschek)

|

|

196? |

(Source: Email from Adolf Minaschek) |

The web site was very informative. It brought back some wonderful memories.

I had just finished a tour in Vietnam returning to Ft. Lee when I went to see the recruiter. I had a few months left before my discharge and wanting to go to Germany. The recruiter made me aware of as a German citizen I could not go. He revealed a secret and promised me paradise. PDC Donges here I come. It turned out to be just that until president De Gaulle who disliked Americans kicked us out.

My unit was Terminal District US Army Petroleum Distribution Command Donges, APO US Forces 09681, HQ Fountainbleu.

I do have some technical data about total storage capacities. Donges capacity at tank farms A, B, C and D totaled 1,541,000 bbls.

Texaco fleet tankers (230,000 bbls) out of Port Arthur offloaded their loads at tank farm A. "Ship-to-shore" pumping took 2-3 days and nights. "Main line" pumping operation was from tank farm B which had a low and a high pressure pump house. Pumping started 6 AM-6 PM five days a week.

St. Nazaire and Donges greater area with the beaches and small fishing villages are very pictures. St. Nazaire, during WWII, was an important German submarine base. While stationed there I managed to marry a local national.

Between two tours in uniform and serving as a DAC, I spend 15 yrs in Germany. Enjoyed every moment of it. My first French vaction since I left France in 1966 came in Dec 1973 when I was stationed in Nuernberg. The 15 yrs we were in Germany we went to France each year.

My flag orders back to the US came in Augsburg in Sep 1995 when I was a DAC. Starting in 2002 I visited Germany twice and my wife and I went back to France each year. Hoping to go this summer again.

Being born in the middle of the war in the Czech Republic, I am fascinated about WWII history in Europe. The history of D-Day and it's beaches in Normandy is still like a magnet to me, even though I have visiting three times.

Tanker Off-loading Operations at Donges

I'll try to walk you through step by step. A tanker ship pulls into the jetty. First it's secured and the flexi rubber hoses connected to the ships manifold. My job was to gauge each tank and varify quantity with ships paper work. Next came the lab people to take samples of the fuel.

Each shift consisted of a US pipeline sergeant with a few soldiers. A crew of French workers worked together with the American soldiers. Both crews together opened the necessary rising stem valves for the designated tank farm that had enough storage space for the fuel to be stored. Tank Farm "A" had very little storage capacity. In most cases fuel was transferred to Tank Farm B.

The Texaco fleet tanker deliverd bulk fuel only. The tanker's capacity was 230,000 barrels. The ship-to-shore pumping operation for a tanker was a 24 hr operation and usually took 2 to 3 days. 8 hr shifts were on hand to do the mission.

Main line pumping started at 0600 hrs. The first crew started their duty day at 0400-0800. Day shift came on at 0800-1600 hrs. Tank farms were connected with each other and military pumps were available for transferring fuel as needed.

Packaged products, in my time, were not part of our mission.

Our total strenghth was approx 90 soldiers. |

|

|

|

| Donges Tank Farms ("A" - "D") |

|

Road sign directing to Camp de Sem (= Tank Farm "B") (Adolf Minaschek)

|

|

Tank Farm "B" seen from N171 (Adolf Minaschek)

|

|

(Source: Eamil from Adolf Minaschek) |

Brief Description of Tank Farm "A" (at Donges)

I don't remember Tank Farm "A" that well. There were no MP's or guard shacks located at any of the tank farms. Camp de Gron was the only facility that had a French civilian to control incoming and outgoing traffic. All other facility gates were locked at all times.

I do remember seeing truck filling racks (fuel racks for tanker trucks to pull under and fill up). The racks were not being used. I also remember a storage area with 55 gal drums. Quantity never increased or decreased. And I remember railroad sidings but they were also not being used. When I arrived in 1964 (many of the original) operations were already stopped and we were downsizing.

Tank Farm "A" itself consisted of a row of six tanks. Tanks #3 & #4 had a capacity of 63,000 barrels each. Con shaped roof. 138 ft in diameter. Tanks #1 & #6 only had a 10,000 barrel capacity each; also cone shaped roof. #2 & #5 each had a capacity of 24,000 barrels; 73 ft dia; cone shaped roof.

Along the right bank of the Loire River estuary was the jetty - or dock - for the fuel tankers.

Brief Description of Tank Farm "B"

The main entrance to the tank farm was at the northern end of the facility. There was a parking lot for vehicles just inside the fence. (As a SP/4 we needed permission from our CO (1LT Osborne) to purchase an automobile. I have a copy of my request for purchasing my 1965 Opel Kadett in front of me.) The entrance was at the lowest elevation of the entire facility. Everything else goes up fast. The tanks were at the top of the small hill.

At Tank Farm "B" there were 6 large tanks: one tank in the middle and the other 5 neatly positioned around it. Capacity of each tank: 84,000 barrels. Floating roof tank. Diameter: 120 feet, Weight of the roof: approx 114 tons.

I do remember two pump houses (a high pressure pump and a low pressure pump) -- one of them can be seen in photo #2 showing four exhaust pipes on top of the roof. |

|

|

Two national flags side by side at Camp de Sem (Tank Farm "B")

|

|

Half way up on a plateau were the US and French flag poles with tables and chairs. The lab (used for testing fuel samples for quality) was located in a white bldg. (This was the only lab in the district.)

Photo #1: Adjacent to the parking lot were several buildings - break & lunch rooms, administration bldg, equipment bldg. The small bldg on the far right, near the fence, was an unofficial guard shack. This building was only manned when people showed up for work. The gate stayed locked.

Photo #2: This was one of the two pump houses - clearly visible the exhaust pipes on top of the roof.

Photo #3: If you followed the perimter road shown in the photo you would reach the top of the hill and be able to see all of the tanks. |

|

Tank Farm "B"

Donges, France |

|

|

|

|

1. Parking lot and buildings

|

2. Pump house

|

3. Perimeter road to top of hill

|

|

|

|

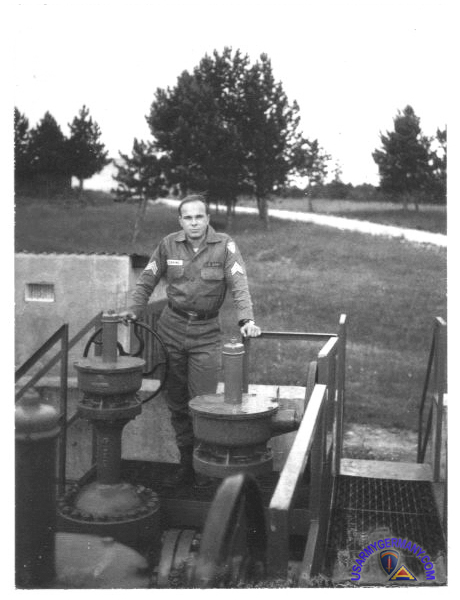

Brief Description of Tank Farm "D" (near Piriac-sur-Mer)

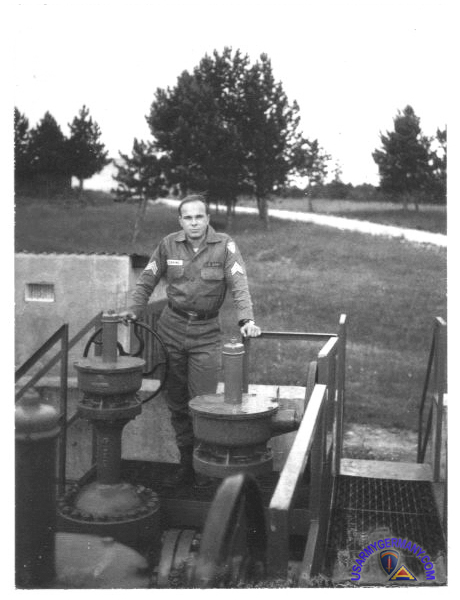

Tank Farm "D" was located on top of a hill overlooking the village of Piriac-sur-Mer along the Bay of Biscay. The tank farm consisted of three large tanks (105,000 barrels each; 134 ft dia.) and a very powerful pump (see photo below).

There was no dock facility like the jetty at Donges. The tankers would use a deep sea anchorage near a buoy that marked the spot where the hoses for offloading were. The hoses were submerged, laying on the ocean bottom. The flexible lines were pulled up and connected to the tanker's manifold and pumping would commence. A tug boat took us from St. Nazaire to Piriac to meet the waiting tanker. |

|

|

The pump at Tank Farm "D"

|

|

|

|

| Chalons Terminal District |

|

1958 |

(Source: Email from Jim Nichols) |

I served at a Petrol Lab. Tech. at Chalons Terminal District near Chalons-sur-Marne, France, from December 1958 to May 1961.

We had 4 tank farms, with offices, lab and pump station on "A" Farm ( ).

We also had a packaged products depot at Billy-le-Grand ( ).

We also had a packaged products depot at Billy-le-Grand ( ) between Chalons-sur-Marne and Reims. Hqs of the Chalons Terminal District was located in a small office building opposite of the Main Pipeline Pump Station on Tank Farm "A". CO of the Terminal District was a Major. ) between Chalons-sur-Marne and Reims. Hqs of the Chalons Terminal District was located in a small office building opposite of the Main Pipeline Pump Station on Tank Farm "A". CO of the Terminal District was a Major.

On Google Earth I can see A Farm and one other of the tanks farms, though two other cannot be seen from Google. I recognize the tanks which were there when I left in 1961, and a few of the buildings, but a lot has changed. Can also see what at the time was a mothballed USAF airbase south of A Farm and where we billeted for some time; later move to Billy-le-Grand barracks.

We were a small outfit - 50 or less Army personnel, and a good many French civilians working for the military. At Billy-le-Grand we had a small group of Polish military refugees (a Labor Service unit) that pulled our guard duty. There were other groups of them serving at other bases and they were organized into a quasi military group providing service to the American military.

We went to Vitry-le-Francois (about 20 miles east of Chalons) for sick call, chapel services, a somewhat larger PX (though smaller than Verdun's), transfer processing, etc. A courier went to Vitry daily to get our mail.

There was an air base (mothballed) where we lived on two different occasions. It was south of A Farm and now shows as a good sized airport on Google Earth. When billeted there we lived in two story barracks that were typical Air Force style with two man rooms and a connecting bath -- much better than Army accommodations. We were billeted there when I arrived at Chalons and had again been moved there a few months before I rotated home. We had no contact with the few Air Force personnel stationed there and there was never any sign of aircraft at the base. Personally, I believe it had been built "in case" and the airman there were just for maintenance.

The mess hall (typical Air Force operation so there was no KP or guard duty) was very near the barracks and we had walkways made of old pallets since it was most often muddy between the two buildings. There was also a club at the airbase. We actually had at least one USO show perform there - an unusual event for us. The club had a bar, one nickel slot machine and a fairly large room with some pool tables and tables and chairs where we gathered to tell stories.

We were bused to the A Farm each morning. Besides that being our primary work place, there was also one commissioned officer and one enlisted on duty each night and each weekend. That was pulled in the office across from the pump station on A Farm. Each night the enlisted man on duty drove the route to check on the other three tank farms to be sure guards (French civilian guards) were on duty. That took well over an hour to complete. The enlisted manned the switchboard and transferred incoming calls to the officer on duty (we had occasional alert scrambles). The only time I was able to call home in my 2 1/2 years at Chalons was during one of my nights on duty. That was allowed with permission, but permission was hard to get.

Reading more on your website starts to bring back more memories. While in France I visited St. Nazaire to see a friend from home who was stationed there. Also visited a couple of the other Terminal Districts in addition to Chalons where I was stationed and also had the opportunity to visit the lab in Kaiserslautern, Germany.

All this brings back many memories. I was there 2 1/2 years. Learned a lot.

I have not had the chance to return to France. Would very much like to visit the area I served. It was a great experience.

|

|

|

| Chalons Tank Farm"A" |

|

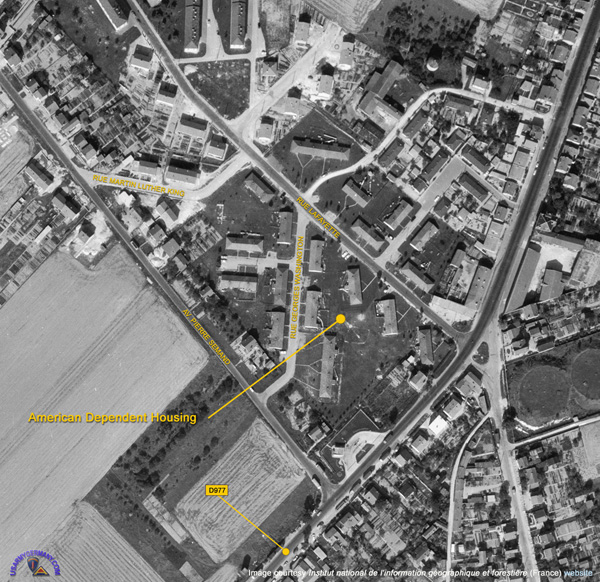

1958 aerial photo of Tank Farm "A", Chalons Terminal District, near Vatry (IGN website) |

|

Referring to the aerial photo above, the "A" Farm is shown on Road D977 and just north of Vatry. As previously mentioned that Farm had the offices, lab, rail and truck loading facilities, tankage, the pump station for the pipeline from the coast to Kaiserslautern, a motor pool and a package products area on what we always called the "South 40".

The other three farms, B, C, and D Farms, were located east of D977 and northeast of A Farm. When pulling night or weekend duty we had to drive the circuit to each of these farms to check on them and be sure the proper guards were on duty (guards were not military personnel). I did that circuit a number of times during my service and know there were no farms west of D977 and certainly none north of Chalons.

I recognize a good bit on the 1958 photo. There was an office on the left just after entering the front gate (this does not show well on the photo); the lab did not exist at the time of the photo but was built across the road from that office (that is where I worked after it was built). The package products area can be seen in the south part of the Farm. Moving to the 1969 photo, you can see two smaller tanks that had been added by then; the packaged products area has been cleaned off and it looks like the lab building had been removed. I met a man where I worked in civilian life who had served as a POL lab tech in Germany several years after I was back in civilian life; he said there were indications the lab building they had, had been moved from France and I suspect it is the building we had. It was a metal building that bolted together so would have been easy to relocate.

When we finally got the petroleum lab at Chalons A Farm, we had four lab techs: myself, Tucker (who I believe made a career in the Army), Ahler and another who I can't remember the name of. Most of the time we operated the lab on a 24 hr. basis, but not on weekends. The NCO over the lab was a sergeant, a crusty old guy who had a bad alcohol problem and had served in WWII. He was still there when I rotated back for discharge in May of 1961.

Somewhere on your website I saw a Capt. Petty mentioned; there was a Capt. Petty who had some authority over Chalons, but not stationed there. I met him on more than one occasion. At Chalons we also had a Sgt. Travis; nice career NCO who served in WWII and had a battlefield commission during the war which was taken away afterward. Upon arrival in Chalons in Dec. 1958 I reported to him. My first assignment from him was to order all the lab equipment that would be needed once a lab was built. That was quite a job for such a young inexperienced GI. I ordered all the glassware, vent hoods, testing equipment, chemicals, even ordered a knock engine, but they didn't provide us one.

|

|

Annotated version of 1958 aerial photo (Walter Elkins)

(click on one of the three red boxes to see a higher resolution image of that area with notes)

|

|

Box A: The front entrance had to be a fairly wide road as you came in to accommodate the 5,000 gallon tankers as they came and went to the truck loading rack. It appears that the front office building (Transportation Office) is barely visible on the left side as you turn left toward the truck loading racks. The loading of tank trucks and tank cars and road and rail movement was controlled out of the Transportation Office. The lab is not visible in the photo, but would have been almost directly across the road from this office. One reason for the lab to be located there was so we could at times sample the product that was loaded for shipment, especially in winter months when diesel and kerosene were blended to be used as heating oil at bases in Germany.

Box B: It will be difficult to define what building is what in this area. As I mentioned earlier, there was the Terminal District office (which seems to still be there) and across the road from it was the main pipeline pump station.

The commanding officer of the Terminal District and his staff worked out of the headquarters building. The switchboard was also located in that building.

The pump station was operated by French personnel under the supervision of two Dutchman who were Shell retirees (most weekends they returned to Holland to be with family). I was only in that pump building a few times to practice taking interfaces as different products were coming up the pipe line.

The buildings shown faintly in the northeast quadrant of Box B were, to the best I know, (transfer pumps used to route products to and from the other tank farms; and to send product to the truck and rail car loading racks.

Box C: The tank car loading rack was quite long and taller than a tank car so as to manage loading, visible inspection of interior of the tank cars, and providing for sealing the top hatch with numbered seals. Not shown in the west side of "C" are two smaller tanks that were added in late 1959 or 1960 and which show up in future photos and now on Google Earth. At times these smaller tanks were used to hold interfaced product when timing of the interface was not caught correctly. As I recall those two tanks were not enclosed in a concrete wall.

There also was a switch engine (Webmaster note: maybe a 45-ton GE switcher?) assigned to Chalons to move the tank cars around for loading and to line them up for hooking to French locomotives for shipment to their destinations. There was a shed for the switcher but I don't see it on any of the photos.

|

|

|

| Billy-le-Grand POL Sub-Depot (Class III Packaged) |

|

1958 aerial photo of the Billy-le-Grand Class III storage site (IGN website) |

|

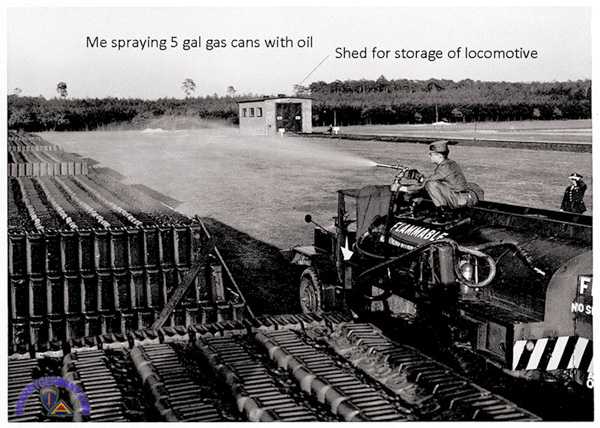

The aerial of Billy-le-Grand above: the "rectangular" images were 55 gallon drums of lube oil (maybe some kerosene and diesel, but mostly lube oil). The "square" images were huge stacks of 5-gallon Jerry cans of motor gasoline. Most if not all this was left over from WWII and was for emergency use. We had a project to empty the Jerry cans since some of the edge cans (exposed to the most sunlight) were beginning to deteriorate. That project is a story in and of itself.

The north/south road by Billy went to Mourmelon-le-Petite to the north and then on a little further north to Mourmelon-le-Grand. There is/was a French Army base out from Grand (we went to it for annual qualification on the M-1). Petite was an active R&R station for US troops during WWII. In later years I met some men who spent R&R time there during WWII and one even married a US Army nurse at Petite that he met while there. The highway at the south end of Billy went to Reims to the west and to Chalons to the east. As mentioned before, at various times we billeted at Billy and also at a US Air Force mothballed airbase just north of Vatry on the west side of D977.

I mentioned earlier a very small PX in the barracks building. It was run by a Frenchman who actually lived in Paris, but came to Billy each week to open and run the PX. It mainly stocked toiletries, beer, soft drinks and a few snacks. The man's given name was Andre -- nice guy who of course spoke good English.

Our food stores for the mess hall at Billy were trucked in weekly from Verdun. Verdun was also where we went to shop at a larger PX and finally got the okay to shop in the Commissary there. At one time I spent a week at Verdun attending a school. The base in Verdun was right downtown and had been a major military installation during WWII.

Back to Billy, it was located on a battlefield of the Battle of the Marne during WWI. Each spring when the facility was disked to control weeds and prevent fires WWI relics would come to the surface -- swords, helmets, rifle shell casings, etc. Besides the barracks and day room at Billy-le-Grand there were a few buildings for supplies, a water tower, and perhaps a small sewage treatment plant. There was very little activity at Billy, work wise, until we had the project to empty the Jerry cans and also emptied some drums of diesel and kerosene. |

|

Annotated version of 1958 aerial photo (Walter Elkins)

(click on the red box to see a higher resolution image with notes of that part of the POL sub-depot) |

|

|

Box D: First, at the front gate there was a guard house that was manned 24/7 by the Polish guards. The building on the left as you enter the gate was the barracks (a two story building with three squad rooms on second floor, mess hall, office and very small PX on first floor as well as quarters for the guards. North of the barracks there was a day room building that was built after we moved there. I don't recall what the other building were. Most days we commuted to the A Farm for work.

As I recall the flag poles, they were outside the front door of the barracks (two story structure). The front doors were in the area where the building becomes wider on the southeast side. The wider part of the building was the mess hall. The smaller buildings behind the two story must have been for storage, I don't recall ever being in them. Neither do I recall the Quonset buildings being there and they perhaps had been removed by the time we moved to Billy sometime in 1959.

FYI, Billy was a great place to live; no guard duty though we did pull occasional KP, but with it being a small outfit it was not hard duty. The day room building had pool tables and I believe we occasionally had movies there.

The square outline southeast of the day room is not familiar to me. There must have been some building there in earlier times. The same holds true of the area in the extreme southwest of the area shown.

I don't recall what the buildings were across from the barracks. I parked my car over there, but have no idea what the buildings were. Scattered around the depot where drums and Jerry cans were stored there were concrete lined fire water pits (thankfully they were never needed). We used those pits to empty drums and Jerry cans which was then pumped into 1200 gal. tank trucks and taken to A Farm to be put in the smaller tanks and eventually trickled into the pipeline when the same product was being shipped up the line. |

|

|

Troop area, Billy le Grand QM Sub-depot

(Photo: IGN website) |

|

(Source: Email from Louis Rothenstein) |

I was assigned to Billy le Grand (BLG) POL Sub-Depot in July of 1956. Was assigned as security, wasn’t needed so I became the company clerk with side job of driving an M-62 5-ton wrecker and a bus. Many soldiers (at BLG) had two jobs.

Originally BLG was subordinate to Metz QM Depot along with another POL sub depot.

The building across from the multi purpose building was the motor pool maintenance building. It was larger than in the photo. At the gate, the fire truck was parked with fire fighting equipment in the building. It was also larger in 1956-59.

The UI bldg. was where the POL pumps and test equipment was located originally. The in-ground water reservoirs I believe there were four – about 12 feet in diameter, about as deep – used at times to re mix fog oil (cut with kerosene when it got too thick). In 1957, we actually did this for much of the Army in Europe. Rail cars would come into Mourmelon Le Petit (our railhead), trucked to the depot, decanned, remixed, recanned, then shipped out. In the winter, the POL Handlers had a really hard job using breaker bars to get the 55 gallon drums loose then loaded up ramps to truck beds.

We had eight M-35 two and a half ton trucks for this purpose. We also had a couple of M-34’s for supply and ration runs to Verdun.

The multipurpose building as described by Jim Nichols also had a supply and arms room, (SFC Er Williams). Our original day room/chapel which was used as billets after the day room building went up. The Orderly Room and Stock Records shared a room and the 1SG (Howard Heern) had an office along with the CO (Capt David D. Rutledge).

The buildings behind the multipurpose building were the utilities – water, electricity, etc.

There were several small buildings at the road junction, the POL types used. Further down we built a ball diamond, barely visible.

The pad near the day room is a game pad – concrete for basketball, volleyball and tennis.

The CG COMZ had it built for us for our outstanding unannounced HQ DA IG Inspection Rating.

The Quonset huts were there replacing 12 GP Medium Tents that buildings were built around. Wood floors, walls, roof joists, plywood coered all with roofing tarpaper. Four plastic screen windows at the sides, doors front and back. Heat by pot belly coal stoves. They were actually pretty comfortable in the winter with the stoves but hot in the summer.

The first and closest to the multipurpose building were the NCO quarters. We had three SFC E6’s there, one lived downtown Mourmelon Le Grand with his wife.

They were all WWII and/Korean War Vets, all CIB, all PH, all reclassified to as they said – pumping gas. In fact, the CO, Capt Rutledge (direct commission) and the XO, Cpt Phelps were also CIB types. All I believe were waiting for the 20 year mark as promotions were rare in the 50’s. A mess Sgt, also an SFC E6 w/CIB, was being put out of the Army for not having three score over 90. He sold gas to locals because of this and needed money to get his family home. SFC (E6) De Stefano was the operations sergeant who ran the show.

The second was our dispensary. One SP4 and PFC M43 Driver. Made sick call runs to Vitry le Francois Med Depot.

The third one was a craft shop with some tools and a photo lab darkroom in the back. I ran this for about a year. The $50 a month extra money let me buy a car.

The next building was the Orderly Room for the 6941st Polish Labor Service Platoon. A 1 Lt Plt Leader lived off post, the Det Sgt was a former Polish Major lived in the back.

The next seven huts were Polish Guard Quarters. The last was a storage area mostly that I recall.

The Quonset huts probably replaced these after most of us moved to Chalons sur Marne- Chalons Terminal District, and I was living at Vatry US Air Force Auxiliary Air Base. I had a standby job of driving a P2 crash truck. Even after our reassignment I lived at BLG for several months picking up French workers for Tank Farm A.

There was a crash project to build drum runs at Chalons as there was a railhead within Tank Farm A. It was a lot of work. I was delivering some special lubricants to Evreaux AB in July of 1958. I was requisitioned and after seeing my first C-130A, flew to Lebanon with a bunch of civilians and SF types on it. After a few months of leisurely spotting and surveillance duty, I returned to find much of BLG gone as far as POL products.

When BLG was placed under Chalons Terminal District in the PDC, things changed rapidly. Some troops were living at BLG and working in Chalons, some were living at Vatry.

It was a bit more than confusing. When I was made an admin specialist at Chalons, I was also supporting US Liaison Offiers teaching at French Army Schools, Artillery, AAA, Armor. I ran the projector and moved the films around to different French Army Schools.

I left France in December of 1960.

My memories are mostly of the hardest working soldiers I have ever worked with when a job came up, they pitched in and finished it ASAP. At times they worked under truck headlights. We had no materials handling equipment at Billy-le Grand. It was all hand labor.

55-gallon drums were rolled up wooden planks by two or three men with two in the truck setting them up. 5 gallon cans carried by hand – about four at a time by the stronger guys were handled with a toss.

We often received products without advanced warning – they just showed up at the railhead or pulled into the depot by S&P.

I believe my assignment convinced me that I should make the Army a career. I left France as an E-5. I retired in 1986 as a CSM.

ADDITIONAL INFORMATION

Thanks for posting it. If you can locate SGM (Ret) William E. Render, he was at Melun, Billy le Grand and Chalons. He was sort of a de facto operations sergeant at Chalons working with SFC Travis mentioned before. He was in France I believe until closing down came about. He would have some added details. Bill operated a pipeline in Vietnam and a pump station on the pipeline in Korea near Taejon. SFC Tucker, the POL Lab guy was also there. I visited them when I was on the Eighth Army IG Team.

I recall during the move of packaged POL from Billy Le Grand to Chalons Tank Farm A, a US Army Engineer unit was constructing additional steel fuel tanks. The four tank farms had concrete as the original. These were added I believe beginning at the start of 1958.

We Billy Le Grand guys worked at building drum runs (I learned how to run a D4 Caterpiller and TD-18 Dozer to level ground. 4x4 wood runs for the drums were used at the start. I think there were about 8 or 9 built near the site of the new steel tanks. Jerrycan stacks were everywhere when I returned from Lebanon and there was sort of an alert status going on even in October 1958.

The advantage was that Tank Farm A had a pretty good rail head. We had a Diesel-Mechanical locomotive that could move 10-12 loaded rail cars and a converted deuce and a half with steel wheels to pull about 2-3 unloaded cars around. The locomotive was the 45-ton model (GE 45-ton switcher)). In the winter, it took some ether to get it started. It was located at Chalons Tank Farm A right next to the French rail line.

The problem at Billy Le Grand was the rail head was at Mourmelon Le Petit, about 5-6 miles away. Had to drive D994 (current map) to Livry then D19 to the rail line/rail head. No US equipment there. Mourmelon Le Grand down the road a bit further was the town the married soldiers lived in. One lived in Mourmelon Le Petit for awhile and one of the Polish guards lived in Livry. His wedding was three days long. He moonlighted as a taxi driver. One of the Polish guards, Czeslau (Chester), joined the U.S. Army, 82d Airborne, then SF. Retired a Major I think in Munich. His last name may have been Havel. He would be a source for anyone writing a book.

A French train started a fire not far from Tank Farm A and the P2 Crash Truck from Vatry AB came in handy to help put it out before the fire got too close.

The pipeline was basically operated by a fellow from Belgium if I recall correctly. His wage scale was different from other civilian workers.

Most of the Polish Labor Service Personnel from Billy Le Grand were spotted around the four tank farms for security in addition to the French security. They had bunks in the guard shacks. The worst part of duty at Chalons was the jeep drive around all of the tank farms for a security check.

You may be aware of the US Army Transportation Corps rail car storage at the railyard at Sommesous. That was about 8-10 miles South of Vatry near N-4. There were at least two hospital trains there and some special purpose cars on the sidings. There was a bunker there as well, large, steel doors, contents unknown.

It is funny how things pop up from distant memory. I recall the phone number at Billy Le Grand was Katorz (14) Le Petit Loges.

Some of the other that returned was a fist battle with some French Communists in Reims, a Chaplain who visited us on Friday taking a OH-13 without clearance as a pilot was not available, and flying out for services; And an SFC who had to deliver two of his children on the road to the Verdun Hospital. He got a transfer closer to it.

It was the only unit I was in that never had issued all the weapons we were supposed to have. I think they were locked up in a container that someone lost track of. The Polish guards had M1 carbines.

Some officers were shocked to see that. The down side of duty during the 50's was the elimination of some good NCO's as they had low aptitude area scores. Another was that several Captains were reverted to NCOs as the Army shrank.

SOME MORE INFORMATION

One of the POL handlers built a special lift for 55-gallon drums for use with fork lifts. Lifting 5 gallon Jerry Cans on a pallet worked for about 1/2 a stack. We only had two I remember and they were not very mobile - small wheels - warehouse items. The days before the rough terrain forklifts.

On our runs to Verdun, we usually dropped off 4-5 movies weekly at 1 or 2 102d Sig Bn sites along the MSR. One was not far from Chalons sur Marne (now Chalons en Champagne) and the other near Clermont.

I worked occasionally for US Army LTC Raymond F. Aquilina. He was ADA and taught at the French Artillery School. He was a WWII and Korean Vet and I believe he had a tour later in Vietnam. I picked up Army Training Films from either Seine Area Command or Verdun and ran a 16mm projector for him and occasionally other exchange officers. His family lived not far from Billy Le Grand and would stop by 2-3 Fridays a month to watch a movie with us. One of the French Army schools was at Chalons, using the Mourmelon Le Grand or Camp Chalons Training Ground. Chaumont and as far away as Saumur were others I visited.

What was a culture shock is being woken up in the morning with an attendant and cart, pouring you a Cafe au Lait at bedside. The other was drinking large glasses of wine at really big lunches. The French BOQs were like cabins aboard a ship. One could rarely shower on Saturdays. Long lines were always present on that day.

As I jog my memory a bit, I recall that we learned not to do very much on Friday afternoons. Most of the workers went out for a big lunch, and falling asleep was a common event so the military side also shut down to minimums where possible.

For several months I drove a Fageol Twin Coach (ambulance type bus) as I lived at BLG, picked up French workers at the Mourmelon and Chalons train stations, then to Tank Farm A. Usually, someone else drove them back as I did a security sweep and delivered mail to our several billet areas. The bus was used for passes in the evenings locally and after inspection Saturday AM, would transport soldiers to Paris via Reims. Place Pigalle, of course. The Gendarmes had us park it near their call box. We had to pick up in Reims then be back by 2200. It worked fairly well.

I often wondered if these workers worked at their same jobs until they retired and how they were payed after we left France. I know most of the Polish Labor Service Guards eventually settled in France although a few like Chester went to the U.S. under the Lodge Act.

You probably have read the attached story in some form on the Jerrycan. The finding of your website sort of brought back the Jerrycan story. I modified it a bit and sent it to our local Veteran Reporter News. Not sure if they will use it. I will expand it a bit and sent it to the MI Center at Fort Huachuca concerning the technical intelligence aspects.

I think that few even senior military people realize the importance that POL has been in our conflicts. On last look, I believe there was only one USAR pipeline unit - New Mexico. I know we still control the main pipeline in South Korea and I think the old PDC one is lease operated.

On the website, I found the 94th Engineer Battalion (Heavy). I recall it as an airfield construction unit. Around 1958, I was held up for two hours by this unit moving from France toward Germany on N4 near Metz. A WWII Bailey Bridge took a few vehicles at a time. The unit had a cement plant-associated equipment. Later, someone told me they were the size of 3 or 4 engineer battalions. I am not sure if they built Vatry AB but it was B-36 capable.

The 535th Engineers built our dayroom and game pad at BLG along with a few dump trucks I think from the 520th Engineers. I cannot recall what engineer unit built the POL tanks at Chalons.

|

|

|

| Buzy POL Sub-Depot (Class III Packaged) |

|

|

|

(Source: Email from Louis Rothenstein) |

The other POL sub-depot that was under Metz QM Depot was Pouilly POL Sub-depot. Not as nice as Billy Le Grand.

I am not sure of the exact location. A map I brought up online showed a Pouilly south of Metz, and I think this must be it.

I was at Pouilly a couple of times - softball game and loan of pumps. They were also involved in thinning out Fog Oil. |

|

|

| Pouilly POL Sub-Depot (Class III Packaged) |

|

|

|

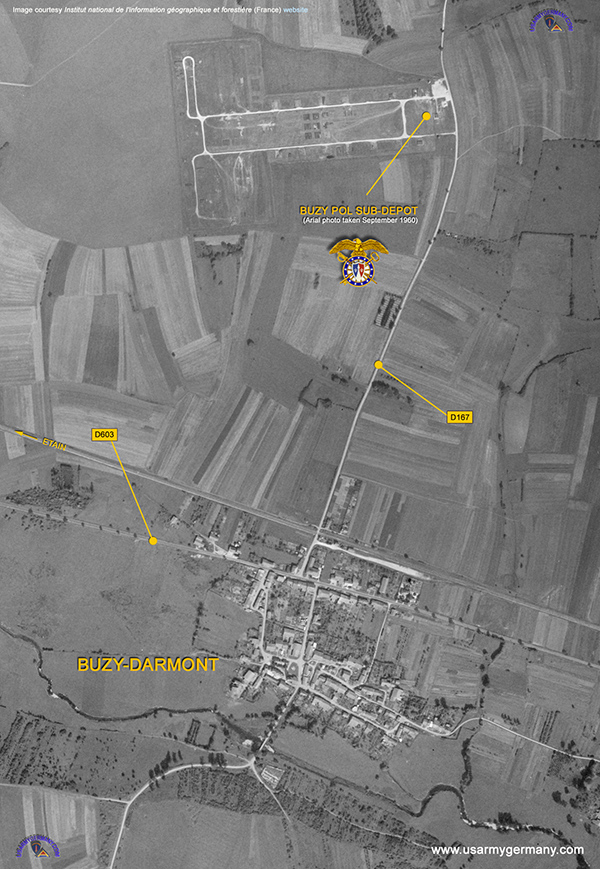

(Source: Email from Louis Rothenstein) |

The Buzy POL Sub-depot also pops in mind. It was located near (southeast) Etain, east of Verdun. Perhaps two hours drive from Billy Le Grand. Metz was about two and a half hours.

I am not sure if it was under Metz QM Depot originally. It was not very big. |

|

|

| Chalons-sur-Marne American Dependent Housing |

|

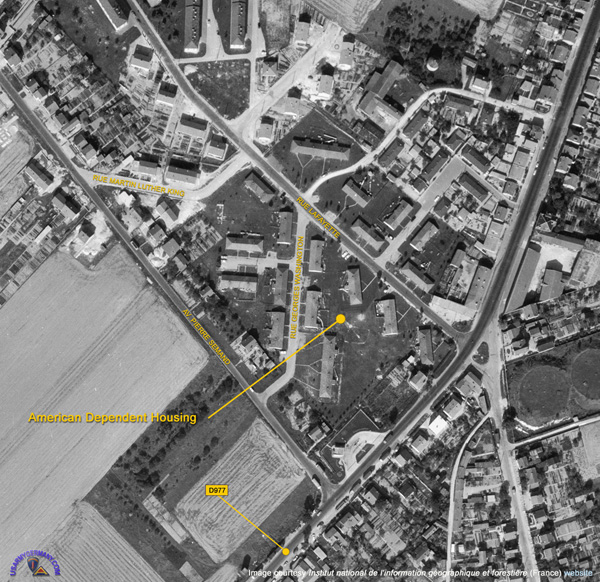

American dependent housing area in Chalons-sur-Marne, 1962 (IGN)

American dependent housing area in Chalons-sur-Marne, 1962 (IGN) |

|

Personnel assigned to Chalons Military District, accompanied by family and authorized government housing, were given quarters in the American dependent housing area in the southern part of Chalons-sur-Marne (now called Chalons-en-Champagne) ( ). ).

Grade school children were bused to the American Dependent Elementary School in Vitry-le-Francois.

(Would like to hear from anyone with information or photos of the housing area during the 1950s or early 1960s - webmaster.)

|

|

|

|

| Melun Terminal District |

|

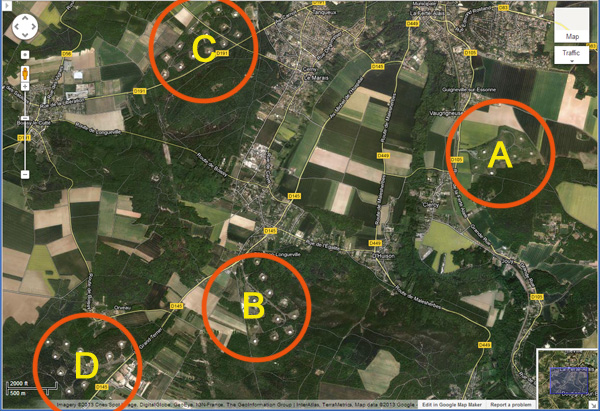

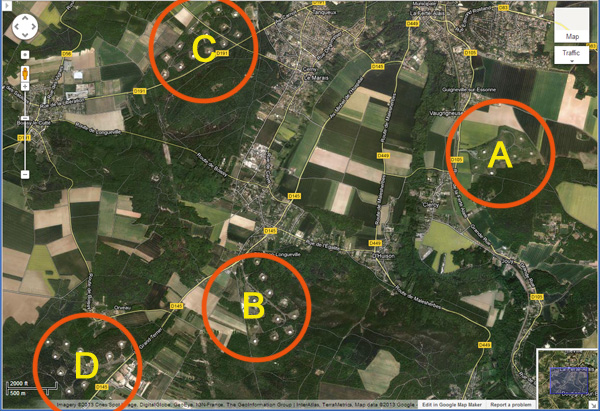

Melun Tank Farms near La Ferté-Alais (GOOGLE Maps)

|

|

Melun Tank Farm "A" on May 24 1961 (IGN website)

|

|

Melun Tank Farm "B" on May 24 1961 (IGN website)

|

|

1960 |

(Source: Email from Cornelius "Neil" Eckerson) |

Went to France in 1960 but our radio equipment failed to follow. The unit designation was Melun Terminal District though we were not actually in the town of Melun. (Webmaster note: the four tank farms were just south and west of the town of La Ferté-Alais -- click on the GOOGLE Maps image above for a recent satellite view of the area.)

The unit was small (about twenty soldiers) but we had a large French civilian worker contingent. Since we signalmen were at a loose end the unit used us for other jobs. I busted truck tires for awhile then began driving semi tanker trucks delivering fuel to other units and then a truck wrecker. I made many trips to Germany and other parts of France, usually alone. I was a tourist at government expense. I picked up some French and even served as interpreter for the base commander on occasion. There were civilian employees other than the French. There were three engineers, one British (future father-in-law), two Dutch, and an American who oversaw Public Works. The American was not an engineer but was Army civil service. If you know someone else who was there that would be interesting because I knew everyone.

There was no caserne for the terminal district. We were given a plot in open country that a big WW2 battle had been fought on. It was full of unexploded ordnance so the Army dumped 14 feet of earth fill on top of previous grade. We were always digging something dangerous up and would have to call EOD to handle it. Our post consisted of four “tank farms” that were several miles apart from each other. The farms were POL storage tanks behind fences with manifold and pump houses to move product around and to load POL onto train tank cars and tanker trucks. My signal stuff was on the farm that had our HQ building, mess hall and barracks (Tank Farm "B").

The unit had many railroad MOS soldiers, engineers, conductors and brakemen because we had a siding for Army train cars that we filled on order for the U.S. Air Force jet fuel needs and we supplied heating oil and motor and aviation gasoline for surrounding U.S. housing areas and army units. Our base had, I believe, 6600 barrel storage tanks that were resupplied by the TRAPIL 12-inch pipeline that ran from Donges (St. Nazaire), through France, to 7th Army in Germany. The pipeline had a pump station every forty miles or so which were operated by French engineers. There would be a U.S. Army post about every 120 miles.

I worked in the resupply office for a while where my main job was to call U.S Air Force bases in France and Germany to determine their jet fuel needs and to track their fuel supplies and if need be to begin the process of resupply by truck or tank car via the French railroad system. I meet a young woman at the base who was a civilian worker; she was secretary to the commanding officer and to her own father who the civilian Post Engineer. We also had a military Post Engineer but the civilian engineer was a pipeline expert who had worked for oil companies in the Middle East for many years. I eventually married the young woman and we had twenty-five years together before I lost her in 1989.

Tank Farm "A" -- I pulled up some French road maps and could see the secondary roads that used to be the main roads. I drove them enough times. It looks like the French ran what would be a freeway to us right through the middle of the area; that’s what confused me at first. The "A" farm (see 1961 aerial photo above) was the only place we could fill a 5000 gallon tanker trailer. The area to the north of the buildings and the loading area was empty -- later we stored thousands of jerry cans at that location. Also, an SNCF railroad line ran right past tank farm "A," we had a spur right off that line. I re-read the Army-TRAPIL contract and saw where Quartermaster Petroleum

District ordered a rail line spur for the “La Ferte Alais Depot”. We also used the La Ferte

train station to receive cans of oil and artillery grease and a crapload of

jerry cans but since we paid demurrage on track space at the La Ferte station

I’m thinking we did not have a spur there.

Tank Farm "B" -- "B" farm (see 1961 aerial photo above) had a large warehouse, and our only motor pool with a shop and vehicles parked in the open. There was an Army Engineer storage area with bulldozer, road scrapers and trailers used as offices. Follow the entrance road to a right turn off the main entrance road, about half way down and in the approximate middle of the photo. The Administration building will be on your left and the post theater will be across from the Admin building on your right. The Admin building was the HQ for the four tank farms. I swear I can also see some old radio equipment trailers that were there when I reported. They were late 40s or mid-50s vintage and were never used. I inspected them shortly after arriving.

The radio equipment finally arrived and I (with the help of the Army Engineer company temporarily based with us) built and installed equipment for two high-frequency radio stations. The antenna siting was so spot-on that my installation was designated Alternate Net Control station. Net control station was normally based in Fontanbleau France.

The small signal detachment was a new wrinkle - we came under the technical command of the existing signal organization, but we and the radios were there to support the pipeline system. The TRAPIL pump stations operated their own teletype landlines but the command wanted a system that would be under the command of the army with radio capability. The signal equipment was all HF. AN/GRC-26Ds. Radio, voice, RTT and CW capability.

The radio equipment was mounted in a hut on the back of a 2 and a half-ton truck with a PU-95 trailer-mounted power unit. I made them ground-mounted with a permanent antenna system and commercial power per Signal Command order from Fountainbleau HQ.

A small contingent of signalmen were located at each terminal district. Many of the team members had gone to Signal School with me. You could tell who they were by their CW “fist”.

I remember being asked by the First Sergeant to welcome and help settle in a WW2 veteran who was joining the outfit. I was a young sergeant and helped him with his kit and took him to where he would be staying in the NCO quarters where I also lived. He came into the room, suddenly stopped and asked “Is Milly La Foret in that direction”? He was dead right in the direction and I asked him if he had been where we were standing right now. He told that he had been in an artillery battery that was firing on the Germans in Milly during WW2 right from the spot where our building was now standing. He also knew the correct distance to Milly-ten kilometers. He then said “there’s something wrong though, we’re too high”. I told him we were on 14 feet of earth fill and now stood higher. Talk about a small world. We became good friends and he came to visit me when he was later posted to the Fort Benning Marksmanship Unit as an ammunition expert.

I came across the TRAPIL-U.S. Army pipeline contract on-line just last night. I was allowed into the TRAPIL pump station which was normally off-limits to us. One reason was my future father-in-law was going there and asked if I wanted to come along. I sometimes made diesel fuel deliveries to other TRAPIL stations when they had delivery problems. Sometimes there would be a pipeline or valve box leak and I and the C.O. and the POL officer would go to the problem area and confer with TRAPIL engineers. That’s when I got to show off my bad French since the officers didn’t speak a word. The engineers were just glad they had at least one GI that could communicate.

I had many adventures in my travels around France and Germany and met many decent people. Maybe having some French Huguenot ancestry helped me with getting on with the French (even though the Huguenots were protestants).

I left France in 1963 to attend OCS in Fort Benning Georgia.

|

|

|

|

|

| Metz Terminal District |

|

1964 |

(Source: STARS & STRIPES, Sep 12 1964) |

A 391-mile Foot

The Army's Big (12) Inch Pipeline

By Ray Wright, S&S Staff Writer

CHALK UP another name on your list of little-known but indispensable outposts in Europe: St. Baussant, France.

Choppers churn, jets zoom, motors roar and wheels turn at NATO military bases because of the St. Baussant layout.

The proper title is Metz Terminal District of the U.S. Army Petroleum Distribution Comd. The men who turn spiggots in the complicated pumping station, check gauges and run multitudinous lab tests are, in reality, the backup crew for every military air or ground maneuver.

Jet fuel, aviation gas, diesel fuel, motor gas and kerosene emerge from the U.S.-owned pipeline at St. Baussaut after a 391-mile journey from Donge on the Atlantic coast near St. Nazaire.

The pumping station at St. Baussant is the point at which the products are diverted into NATO pipelines that run to bases in Germany and northeastern France. Where pipelines don't reach, the station loads the fuels into truck or rail tank cars. |

|

Map

Map

St. Baussant storage facility |

|

Fifteen million gallons of diesel fuel alone went out in tank trucks and 1.5 million gallons into rail tank cars in fiscal 1964. Motor gas -- the kind you use in your POV -- was shipped to the tune of 4.5 million gallons. These figures don't include the millions and millions of gallons of aviation gas, jet fuels and other products that sluice through the NATO pipelines direct to bases.

The dispensing operation at St. Ballssant is strictly a wholesale setup. Unless you're interested in at least 5,000 gallons at a clip, the pumping station won't do business with you. The "you" in this case refers to accredited NATO customers, not individuals.

The boys who jockey 5,000-gal. tank trucks to the consumer bases belong to the 55th Transportation Truck Co and are billeted at Tool, 25 miles away. The trucks clear from the tank farms at the rate of 65 to 75 a day.

|

|

|

The fuels come to Europe by tankers which are off-loaded into the U.S. pipeline at Donge. The fuels then gurgle through the 12-inch pipe to two tank farms 11 miles apart, midway between Nancy and Verdun.

However, before the fuels can be parceled out to customers, the lab runs careful checks for quality and purity. Six tests are run on an average for each analysis, and the lab writes up some 17 analyses each day, calling for a night shift as well as day work most of the year in order to handle the work load.

The drum fill plant at "A" farm is another busy spot. It consists of one feed header connected through a strainer to three steel hoppers, each partioned with baffles to make four compartments -- 12 compartments in all.

Twelve drums can be filled simultaneously since each compartment is fed exactly 55 gallons, then drained when one handle linked to four quick-opening valves at the compartment bottoms is opened by the operator.

Three of the five kinds of fuel can be drummed at one time or, depending on compatibility of fuels, one can follow another. When the products are incompatible, the hoppers are treated to a quick flush to carry off all traces of the first fuel before a second is let in.

HEADQUARTERS for the whole setup is at Fontainebleau under the title of U.S. Army Petroleum Distribution Comd. The NATO offices that keep track of fuels sent to member bases are headquarlered at Nancy under the name of 3rd Region Central European Operating Agency (CEOA).

On the private-life side of being stationed at St. Baussant, the men have taken up horseback riding with enthusiasm, and a number have bought their own mounts. Their PX shopping is on the minimal side -- an 8 by 10-ft. shopping center can't carry a very extensive stock. They have movies several times a week in the combined theater-chapel, and a barber comes to the station twice a week.

"Sometimes we feel a little out of the mainstream of military life," commented Maj John Hollinger Jr., Metz Terminal District CO, "but our job is vitally important and the men here realize this and cope with the lack of advantages here that they would have on a big base. They use considerable originality, too." |

|

|

|

Metz Terminal District & St. Baussant Tank Farm, June 1961 (IGN website)

|

|

Barracks at St. Baussant Tank Farm (Carter Doering) |

|

1965 |

(Source: Email from Greg Webb) |

I was at PDC Metz and PDC Melun from Jan 1965 through Aug 1966 when the Army’s welcome (in France) was recinded. Ended up in Vietnam. Now a retired clinical chemist in St Louis. Do you know anything about Maj Hollinger, Capt Pickel, Lt Abdella, Sgt Grumley or Winkelman?

I arrived at PDC Metz in January, 1965 after a fun trip across the N Atlantic in winter. There were approximately 50 permanent staff at the terminal. This staff operated the lab, pumphouse, bulk storage, and rail and truck loading rack. In addition, there was a small signal group and the usual supply, motorpool, and administrative staff.

The 55th Transportation Company provided tanker fuel hauling but were assigned to the Toul Army base about 20 miles away.

The facility was really nowhere near Metz but by a very small town named St Baussant. It is almost impossible to describe how rural the area was but the staff became extremely close working the site. We were commanded by Maj John Hollinger, had a Capt Pickel as exec and a company commander a Lt Abdella. In addition there was an operations Capt

whose name I have forgotten but who was extremely well liked. There were several DAC’s who were far above me. I do remember one Englishman who was extremely sharp. A key man was our company clerk, Charles O’Roark. He was raised bilingually and spoke unaccented French. Since we were a “hardship station” we got free 16mm films- 2nd run of course.

We had some French nationals who worked there. I remember a lot of names but have forgotten many also -- 45 years can do that.

Half WWI was fought at St Baussant -- the town was flattened (google it to see the pictures). We used to go out to the trenches and still find stuff from WWI. Everyone seemed to get along rather well and the job was done extremely well.

I was transferred to PDC Melun about 9 months later. Very different. About twice as many (maybe more) staff. The base was at LaFerte Alais, about 45 minutes from Paris and very cosmopolitan by comparison. For some reason, I do not remember the officers very well except for a Lt Dulolo (sp?). I worked for an SFC named Tenwinkle -- a very good guy who was bilingual. He married a French woman

who was a sweetheart. The staff member I remember most was a SSG George Washburn. Successful poker player.

As I recall, there were multiple tankfarms at each location and all were used constantly.

In August of 1966, we received word that President deGaulle had asked the Army staff to leave France. I was among the first to be sent back to the US. I joined a brand new unit at Ft Lee. With almost a year to go on enlistment, take a guess where the unit and yours truly were headed. Made Sp5 before I went to Ft Lee,however.

I do remember Carter Deering from PDC Metz. He was there long after me.

Good memories of a long time ago. We got the job done, worked well together and fulfilled our mission. Feel free to communicate with me. My perceptions are probably different from many others because the lab was off to one side of the operation. |

|

|

| Metz Tank Farms ("A" -"D") |

|

Main entrance to the former St Baussant Tank Farm (Claude M., France) |

|

Part of the St Baussant Tank Farm installation (Claude M., France) |

|

(Source: Email from Carter J. Doering, 1964-67) |

Was wondering if you had any information on the Petroleum Depot at Metz (Saint Baussant), France? It was part of the Donges-Metz Pipeline and Transportation system.

I was sergeant of the tank farm and when the French, under DeGaulle, withdrew from NATO, I was left to run the place with a lab tech and 40 civilians. Our command center was originally in Fontainebleau and then moved to Germany. We wore the COMZ patch and it was out in the boonies.

I'd be interested if you have had any inquires from others who served in this command. What has happed to the pipeline these last 40 some years and anything else that might be relevant.

Carter Doering |

|

|

Some of the POL tanks at the former St Baussant Tank Farm (Claude M., France) |

|

Sgt. Carter Doering at the St. Baussant Tank Farm, ca. 1965

|

Response

(Source: Email from Claude M., France)

*About the Metz Terminal District @ St.BAUSSANT, France*.

Carter Doering has requested some news about the place where he served during the Cold War.

I went to St.BAUSSANT yesterday. Weather was exceptionnaly good.

The facility is still here and in outstanding shape. All seems to be running smoothly & with efficiency (pretty scarce in France). I had some trouble in finding it, it is lost in the middle of nowhere. Horses have disappeared. Only cows remaining. Nobody has taken up with cow riding, though.

I wasn't able to enter the site. The boss was not on the premises, so I took some pictures that you will find attached.

I don't know if the pipeline coming from Donge is still active. But for sure there are a lot of trucks loading fuel here every day. I guess fuel is coming from the ports at the North Sea. I have asked TRAPIL (SOCIETE DES TRANSPORTS PETROLIERS PAR PIPELINE : http://www.trapil.fr/fr/pipelines_reseaux.asp) if the former American pipeline is still in service. Probably not, if you take a look at their map on their website.

I am awaiting for their answer, if there is any answer. |

|

|

|

|

| Zweibrücken Terminal District |

|

1961 |

(Source: STARS & STRIPES, Jan 5 1961) |

Zweibrücken Terminal District

The Zweibrücken Terminal District is one of five terminal districts in Europe under the US Army Quartermaster Petroleum Distribution Command located at Fontainebleau, France. It is the only terminal district located in Germany; the other four are in France. CO of the Zweibrücken Terminal District is Lt Col Robert M. Dill.

The Zweibrücken Terminal is responsible for supplying petroleum products to Army and Air Force (and some NATO) installations throughout Germany (two-thirds of all fuel delivered to US military in Europe goes through Zweibrücken). The POL products include jet fuel, gasoline, solvents, diesel fuel, aviation gas and a number of "packaged" products such as lubricants, greases, oils and hydraulic fluids.

Most of the fuel is delivered to Zweibrücken through a pipeline system that reaches from the port of Donges, France, where tankers unload their cargo into the pipeline network. The underground pipeline network includes powerful pumping stations and huge storage tanks interspersed at regular intervals along the 300+ miles between the French coast and Zweibrücken.

Zweibrücken operates a spider-web of underground pipelines (6, 8, and 10 inches in diameter) that extend from its headquarters area eastward to the Air Force and Army installations. The terminal also delivers its products using 16,000-gallon tank cars (German railroad) and its own fleet of 5,000-gallon POL trucks.

Shipments are expedited through six Army-owned and operated installations scattered throughout southern Germany and four sites at major German cities that are German operated under contract to the US Army. Two of the former facilities are the Walshausen pumping station (Capt Lawrence J. Ogden commanding) and the Hinterweidenthal tank farm (Capt John T. Skinner commanding).

In addition to the operations reported above, the Zweibrücken Terminal also operates its own can and drum renovation plant and performs quality testing of the POL products in its own base laboratory facility. |

|

|

|

1976 |

(Source: Army Logistician, May-June 1976) |

Zweibruecken-Huttenheim Pipeline

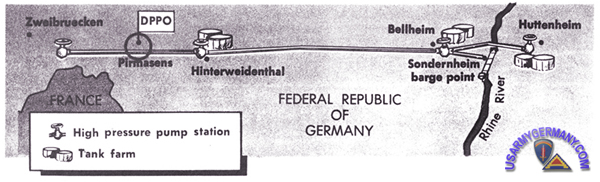

The Zweibruecken-Huttenheim pipeline system is an important part of the network used daily to supply bulk petroleum products to U.S. and allied customers located throughout the U.S. Army, Europe and 7th Army areas. |

|

|

|

|

Fifty-five miles in length, the pipeline system includes four high pressure pump stations, three tank farms with internal low pressure pump stations, and one barge site.

Hinterweidenthal, Bellheim, and Huttenheim, Germany, are sites of tank farms and high pressure pump stations. The fourth high pressure pump station is located at Walshausen, German. The barge site, at Sondernheim, is operated by Bellheim tank farm personnel. The operational headquarters of the system is the Germersheim Army Depot Directorate for Petroleum Pipeline Operations (DPPO), located at Pirmasens, Germany.

Trucks, railcars, and barges loaded at the three tank farms and the barge site carry products to Class III supply points for issue to the ultimate customers, the U.S. and allied military forces supporting the North Atlantic Treatv Organization (NATO). The trucks and trailers are organic to the 37th Transportation Group of Kaiserslautern. The barges are privately owned and are contracted for either delivery or pickup. The rail fleet is controlled by the DPPO transportation officer. With over 400 German-built rail tankers in use, the vast majority of ground fuel provided in Germany today travels by rail at some time. A complex system of rail car management allows the DPPO to have sufficient full tankers in the rail system at all times to support the forces.

DPPO dispatchers coordinate with the Central Europe Operating Agency of NATO for the distribution of jet fuel to customers from Walshausen through the Bitburg loop line. This line connects Walshausen to eight U.S. Air Force bases and several West German Air Force bases.

The Zweibruecken-Huttenheim pipeline is connected to the American-built Donges-Metz pipeline, which carries most of the Department of Defense fuel that travels through France. The Donges-Metz line is operated by the Trapil Corporation, a quasi-government organization. Petroleum products are pumped from Metz through the St. Baussant-Zweibruecken line to the Zweibruecken-Huttenheim line at Walshausen.

Facilities along the Zweibruecken-Huttenheim line are contractor built. Virtually no U.S. military standard equipment is employed.

Most of the system was built in the late 1950's. The Rhine River crossing from Bellheim to Huttenheim was completed in 1959. At that time most of the storage at all three tank farms consisted of bolted steel tanks. The first permanent, welded, partially buried (cut-and-cover) tanks at Bellheim were completed in 1957, and the high pressure pump station was completed in 1958. At Huttenheim the first cut-and-cover tanks were finished in 1962. NATO completed four more of these tanks in 1961. In 1973 the three tank farms together received 4 additional 60,000-barrel tanks, and Huttenheim received the high pressure pump station.

The pipeline network is a central element in the daily supply of bulk petroleum products to U.S. and NATO forces in Europe. The Zweibruecken-Huttenheim pipeline system, with a gross storage capacity of about 2 million barrels, is a vital part of that network.

The ALOG article was written by Capt. Harry W. Johnson, Jr. Captain Johnson is the officer-in-charge of the Huttenheim tank farm. He holds a B.S. degree in business administration from Virginia Polytechnic Institute and State University. |

|

|

1978 |

(Source: Department of the Army Historical Summary: FY 1978) |

The Army Energy Program

... In the second development, in August (1978) the Deputy Secretary of Defense approved an Army proposal to transfer the Zweibrucken-Huttenheim pipeline system in Germany to NATO on 1 January 1979. This should improve overall bulk petroleum support to NATO forces in Central Europe. |

|

|

|

1979 |

(Source: Department of the Army Historical Summary: FY 1978) |

Special Functions

... In a related development, the transfer of the Zweibrucken-Huttenheim pipeline system to Germany, approved in August 1978, took place on 2 July 1979. The shift placed all central European military pipeline distribution systems under single managership and is expected to enhance the bulk petroleum support provided to NATO forces in that area. |

|

|

|

| Tank Farms in Germany |

|

|

|

| Bellheim Tank Farm |

| |

1960 |

| (Source: Email from John Woods) |

2ND TOUR OF DUTY IN GERMANY (1960-1964)

At the completion of a short tour in the U.S. Army Garrison, Fort Devens, Massachusetts and NCO Academy in Fort Dix, New Jersey. I was again on my way back to Germany aboard the USNS Buckner. My assignment was again with the Zweibruecken Terminal District, however this time it would be with the Bellheim Tank Farm, located a short distance from the town of Bellheim, Germany.

Bellheim Tank farm was part of the pipeline system running from France into Germany. The POL operation of the tank farm consisted of 2 large capacity storage tanks 25,000 barrels each, high pressure and low pressure pumping stations, rail car, tank truck (5,000 gal.) and 5 gallon can fill points. Supporting this operation was a locomotive used to pick up empty rail cars from the Bundesbahn siding in Bellheim deliver them to the tank farm for filling and return to the Bundesbahn for shipment. There was also an administrative office manned primarily by German local nationals to process the necessary documents for all shipments out of the tank farm by either rail car, tank truck or 5 gallon can. Within this structure was also the office of the OIC for the facility Capt. Frank S. Poulos with switchboard and operator. The switchboard if I remember correctly was one that the operator had to manually plug lines into to make connections.

SFC Dolphus Triplett was the NCOIC for all POL related activities. My responsibilities were for the high pressure and low pressure pump stations and the 2 storage tanks. As long as there was pumping thru the pipeline military personnel had to be on site to gage the tanks and control the flow of product by regulating the valves in each pump station These 2 facilities were manned exclusively by German local nationals supervised by Herr Stefan Bast, under the control of military. We also assisted with the loading of rail cars, tank truck and 5 gallon cans as needed.

There was another tank farm located at Hinterweidenthal with similar capabilities. The OIC for that facility was Maj. William Hoffman and not really sure who the NCOIC was. Also located some 15 to 20 kilometers from the Bellheim Tank Farm was the Sonderheim barge location. It was used to load and unload fuel barges travelling the Rhine River. As near as I can remember this facility didn’t have any storage capability and was used for the loading and unloading of barges into and from the Bellheim Tank Farm.

In July of 1963 I was transferred from the Bellheim Tank Farm to the 522nd QM Co located in Idar-Oberstein, Germany to assume the duties as Career Counselor for the Nahbollenbach Depot. This brought me in contact with CWO W-2, A. Leonardo Jr. the Asst Adjutant for the depot who inspired and encouraged me to apply for a commission. I’m happy to say that he was successful and I received my direct commission as a 2nd Lieutenant on October 28, 1964. Shortly thereafter I was transferred back to the states for attendance at the Quartermaster Basic Course at Ft Lee, VA.

This ended my 2nd tour in Germany and started my career as a commissioned officer with assignments to the XVIII Abn Corps & Ft. Bragg, 101at Airborne and 2 tours in Vietnam with the 1st Logistical Command. |

|

|

|

| Hinterweidenthal Tank Farm |

| |

Main gate - former Hinterweidenthal Tank Farm (Thomas Neser) |

| |

|

|

|

| 993rd Quartermaster Petroleum Products Laboratory |

|

(Source: STARS & STRIPES, September 2, 1966) |

The 993rd QM Petroleum Products Laboratory is stationed in Kaiserslautern, Germany and is subordinate to the Petroleum Distribution Command, Europe.

The PDC is responsible for operating the US Army pipeline which supports 7th Army and USAFE. This line runs from Donges, France to Huttenheim, Germany, a distance of 533.7 miles and has connections to the NATO pipeline system (CEPS).

PDC operates additional laboratories in France, at Donges, Melun, Chalons and Metz, as well as a mobile laboratory located at the tank farm in Bellheim, Germany. A total number of 45 personnel are assigned to the various labs, 21 of which are at the 993rd in Kaiserslautern. In addition to the lab personnel mentioned previously, two additional technicians belonging to 7th Army also work in the Kaiserslautern lab. They assist in analysing 7th Army POL products.

Besides moving pertoleum by large tanker trucks of the 97th QM Battalion, the PDC has over 500 rail tank cars that it uses for moving large amounts of petroleum from the command's tank farms throughout Germany. |

|

|

|

| Central European Pipeline System (CEPS) |

|

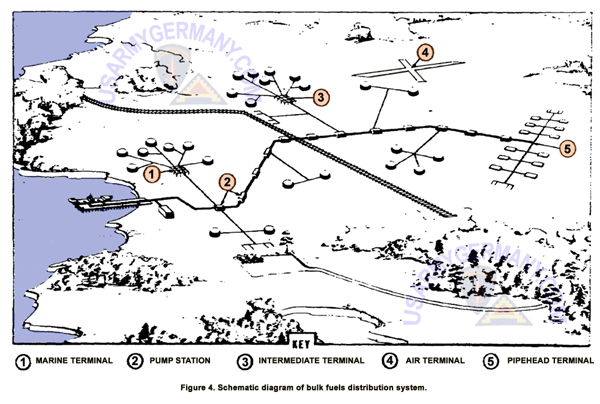

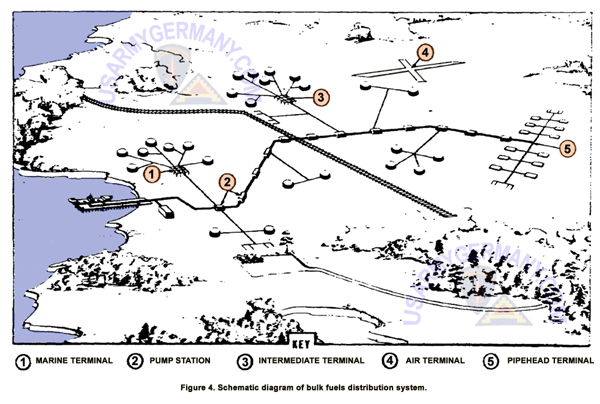

Schematic diagram of bulk fuels distribution system in a developed theater of operations |

|

|

(Source: Quartermaster PB, Summer 1989) |

European Military Pipeline System |

|

|

| |

| Related

Links |

|

|