| If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany' frameset |

||||||||||||||||||||

39th Engineer Group (Construction) |

||||||||||||||||||||

|

|

||||||||||||||||||||

|

||||||||||||||||||||

|

|

||||||||||||||||||||

| Group History | ||||||||||||||||||||

Headquarters building, 39th Engineer Group, Rheinland Kaserne, Ettlingen |

||||||||||||||||||||

| 1950s-60s | ||||||||||||||||||||

39th Engineer Group DUI

39th Engineer Group DUI |

||||||||||||||||||||

| 1970s | ||||||||||||||||||||

39th Engineer Group DUI (approved July 2, 1970)

39th Engineer Group DUI (approved July 2, 1970)In January 1971, the 39th Engineer Gp (Const) and one construction company from (each of) its two member battalions, the 79th and 94th Engineer Battalions (Const), were inactivated. The Asphalt Section of the Engineer Equipment and Maintenance Company (A Company) of these battalions was also eliminated. These battalions were then assigned to the 24th Engineer Group (Const). |

||||||||||||||||||||

| If you have more

information on the history or organization of the 39th Engr Gp, please

contact me |

||||||||||||||||||||

| 1953 | ||||||||||||||||||||

| (Source: STARS & STRIPES, May 18, 1953) | ||||||||||||||||||||

| 2nd Anniversary The 39th Engineer Construction Group celebrates the 2nd anniversary since its activation on May 18. During the augmentation of the group in late 1951/early 1952, the following units were added: The Group is currently commanded by Col Ellory W. Niles. In the past 2 years, the Group has been primarily involved in various major construction projects in southern Germany. Elements of the Group have constructed roads, buildings, airfields, athletic fields and ranges in Kaiserslautern, Pirmasens, Heidelberg, Garmsuch, Stuttgart, Frankfurt and various other posts in Germany as well as in parts of France. (1) Webmaster note: -- the 406th Engr Const Bn (Karlsruhe) was redesignated as the 79th Engr Const Bn in February 1955; -- the 354th Engr Const Bn (Nellingen) was redesignated as the 94th Engr Const Bn in March 1955. |

||||||||||||||||||||

| 1955 | ||||||||||||||||||||

| (Source: Email from Kenneth E. Anderson; images scanned by Ms. Barbara Stuem, Ken's daughter) | ||||||||||||||||||||

|

||||||||||||||||||||

|

||||||||||||||||||||

| 1956 | ||||||||||||||||||||

| (Source: Email from Tom Treanor, HQ 39th Engr Gp, 1956-57) | ||||||||||||||||||||

I'm so glad you have a site which goes back into Rheinland Kaserne's history. I was stationed there in 1956-57, with the 39th Engineer Group. Took my wife there last year and hardly recognized the Kaserne. It seemed some buildings were entirely gone - or else my memory failed me. But was pleased to walk her around old-town Ettlingen. My year-or-so spent at Rheinland Kaserne remains very nostalgic to me. That's why my poor wife had to suffer with a side-trip just so I could show it to her.

39th Engineer Group was involved with many construction projects in Germany (ammo bunkers, golf courses, etc.). I was a PFC who worked in the Headquarters building, tracking our heavy equipment through daily reports that came in - I then posted data on charts hanging on the wall. My immediate Non-Com superior was Sgt. Swayze. Above him was Master Sgt. Word. We reported to a Captain (can't remember his name), who reported to Major Stover. For the life of me, I can't remember the Group's Commanding Officer's name or rank. (When I first arrived at Rheinland Kaserne, I was sectioned out to play baseball. So I was put into the athletes' barracks. After baseball season, I was to play football but decided I'd had enough of playing that in freezing weather so requested to go into Headquarters Company. Master Sgt. Bomar was our ranking Non-Com.. Sp. 4 Serge Matulich was our Company Clerk. I've kept up with Serge a little bit.) As with many young men who were discharged after our two years was up, I quickly got into the business of making a living, raising a family, etc. and never gave much thought to "the old days" when I was in Ettlingen. But, as I said, those days were in the back of my mind. |

||||||||||||||||||||

| 1967 | ||||||||||||||||||||

| (Source: Email from Barrett Ripley) | ||||||||||||||||||||

I was browsing Germany sites for a business trip I will make in April and stumbled on the 79th Engr site, then this one. Many of my friends in Germany were in the 79th so it was interesting to see all the material on that unit.

I enlisted with preselection for Engineering OCS in July 1966 and went to Ft Leonard Wood, MO for Basic and AIT and then to OCS at Fort Belvoir. In July 1967 I was assigned to the 39th Engr Group at Wiley Barracks. I was sent to the 68th Engineer Company which had just been attached after being forced out of France by Gen. DeGaulle. After a short period learning about what to do as a Platoon Leader in the Army from my First Sergeant while initiating the Budingen hardstand project that was finished by the 79th Engr. Battalion, I went back to the Group, where I served as Asst. Adjutant, Community Relations Officer (German speaking), then moved to Assistant S-3 doing construction project design and administration with side duty as Classified Document Custodian and Communications Officer. This assignment involved many trips to Engr. Command HQ in Frankfurt as well as hair raising chopper trips to visit projects. Pilots in the air section were all rotated from Vietnam! At the end of my two year tour I returned to Ft Wadsworth on Staten Island for discharge in August 1969. This is the first contact I've made regarding Army service, but I still have good memories of the people I spent time with throughout my tour. |

||||||||||||||||||||

|

|

||||||||||||||||||||

| 77th Engineer Battalion (Construction) | ||||||||||||||||||||

| 1959 | ||||||||||||||||||||

| (Source: THE MILITARY ENGINEER, Jul-Aug 1960, Society of Military Engineers, Wash. D.C.) | ||||||||||||||||||||

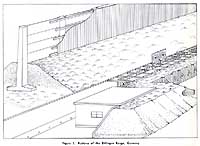

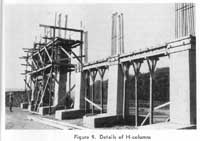

| Troop Construction

in Germany By Col. Laurence E. Lynn, Corps of Engineers Typical of the many construction projects by units of the 7th Engineer Brigade is the reconstruction of a rifle range at Ettlingen, near Karlsruhe, Germany. Karlsruhe, one of the cities in the heavily populated Rhein Valley, has long lacked adequate range facilities for known distance firing. The rapidly expanding indigenous housing has encroached upon impact areas of many of the existing ranges, making their future status uncertain. The Ettlingen range, with an impact area in the Karlsruhe municipal watershed, offered a long-term solution to the problem of providing needed range facilities, but major reconstruction of this range was necessary to meet German safety criteria. The principal features (Figure 1) in the reconstruction were: a reinforced concrete retaining wall, 746 feet long and 10 feet high (700 cubic yards of concrete) ; an earth berm 1,000 feet long and 22 feet high, behind the retaining wall (50,000 cubic yards); a reinforced concrete protective wall with wood facing, 706 feet long and 17 feet high (825 cubic yards of concrete); and two reinforced concrete target sheds (200 cubic yards of concrete). The project was assigned to the 77th Engineer Construction Battalion on June 9, 1959, and preliminary site preparation by the 7132d Labor Service Company (Latvian) was begun. A study of the original design showed that considerable time would be required for the construction. It was highly desirable to complete the concrete portion of the job prior to January 1, 1960, due to prolonged freezing conditions expected in January and February. The 39th Engineer Group, therefore, revised the design of the protective wall to use precast wall sections to be lifted into place after completion of supporting posts. This design was based on a maximum lateral wind load of 30 pounds per square foot over the exposed face of the wall which was to have a compressive strength of 2,500 pounds per square inch. Wall slabs were 13 feet long and 10 inches thick. The posts, spaced on 15-foot centers, were redesigned as H columns with slots, 6 inches deep and 12 inches wide, to receive the wall slabs, which were to be lifted into place by a crane. A spread footing under each post was to provide the necessary bearing and resistance to overturning. Compaction of the portion of the berm below footing level was to be in 6-inch lifts at optimum moisture to obtain a minimum density of 95 per cent maximum modified AASHO standards for the loam-sand subgrade. Construction of the protective wall is shown in Figures 2-5. Construction was begun on the retaining wall on July 17 and completed on September 19. The wall was poured in 20-foot sections. As the wall progressed, work was started on the earth berm behind it, using 50-ton rollers for compaction of the 6-inch lifts. This compaction was considered extremely important in order to prevent any differential settlement of the columns of the protective wall. As the earth berm moved forward, work was begun on the foundations and columns for the protective wall. Because of the height of the foundations (12½ feet) and of the columns (17 feet), considerable scaffolding was needed. Concurrently with this work, 788 slabs were precast for the protective wall, and the target shelters were built. |

||||||||||||||||||||

|

||||||||||||||||||||

| The completion of the concrete work in early December reduced cold weather precautions, with only the heating of the mixing water and insolation of forms being required to effect a satisfactory cure. The Karlsruhe Military Post now has one of the largest ranges for use by American forces in Europe. | ||||||||||||||||||||

|

||||||||||||||||||||

| (Source: Email from Pete Wool, 77th Engr Bn, 1956-58) | ||||||||||||||||||||

|

I spent two years in the 77th (Engr Bn) in Ettlingen from mid 1956 to mid 1958. We were sent on many small assignments but the most memorable was a 200-mile trip to repair the tank trails in Kaiserslautern. We had a dozen flatbeds loaded with D8 dozers with pan scrapers attached which measured about 75ft altogether with three joints; one for the semi and one behind the dozer for the pan.

|

||||||||||||||||||||

|

||||||||||||||||||||

| (Source: Email from Bert Link, 275th EDTC - 77th Engr Bn - 79th Engr Bn, 1957-1960) | ||||||||||||||||||||

I joined the 39th Engineer Group in Jan of 1957 - unaccompanied since no housing was available. At that time the 39th consisted of the

There was also the 7123rd ECB (Labor Service). The 77th Engr Bn had a US Hq& Hq Company and three line companies -- one each from Latvia, Lithuania, and Estonia. All units were located at Ettlingen except the 94th was in Nellingen and the 79th was in Pirmasens. There was a sister 24th Engr Gp. in Kaiserslautern. I have color slides from these units and some of our projects. My personal tour went from the 275th to Hq, 77th, to TDY to the 79th, back to the 77th, then PCS to the 79th. I was involved in some real interesting work, from trips to France for 5 months, to Lebanon for 4+ months, to Morocco for earthquake recovery, and several in-country projects such as tank trails, gasoline removal from the water supply, and actually setting a pump over 200 feet down a mine shaft and adding 10 miles of pipeline to assist the Air Force, among others.

Having arrived in January, I was still learning the ins and outs of an engineer dump truck company and military life in general in March when I was selected to assist in the move of the 79th to southern France for the summer. The battalion was about 80% mobile and to make a one time move required help from other units in the way of tractor-trailers, dump trucks, fuel trucks, and cargo trucks, all with operators, and necessary supervision.

We assembled about 50 to 60 vehicles and convoyed to Pirmasens for load by the battalion. The battalion departed Pirmasens as one unit, stretching out over ten miles along the highway. I don’t remember where our intermediate stops were but we quartered in barracks and a local QM unit fueled the vehicles. This was a three day trip to our destinations of Bordeaux and Captieux. Once we arrived in France we were joined by French MP’s to help us with traffic. On the second day out we made a sharp turn in the middle of a little town east of Paris and headed south. I was in a jeep parked at the corner to insure all vehicles made the turn. One of our tractor-trailers failed to make the turn and was hung up on a building on its right side; requiring backing up to make room for the turn. During this maneuver a civilian car ignored the French MP’s stop signal and hit the trailer broadside, all but totaling the car but little damage to the rig. I took pictures at the scene , filled out the accident report, gave a copy to the French MP, and continued on our way. (This becomes important later – three years later to be exact). We continued to our destinations, off loaded the equipment and headed back to Germany. The return trip took only two days since we went direct to Ettlingen. We returned to Group headquarters and split up the convoy there; most staying there and some going on to the 94th. I can’t think of any thing significant the rest of the year. I was moved to the 77th as S-2 and Asst. S-3 and began working with the Labor Service Units. What follows is a list of the officers I remember: Col Welker, CO of the 39th (riffed back to SPEC6); LTC Fritz, CO of the 77th; 1st Lt Hartman, CO of the 275th; Maj. Rozella Abbott, S-3 of the 77th; 1st LT James Cline, CO of the 175 th; Capt. Homer Ambrose, CO of HQ CO, 39th Gp; CWO Calvacante, Supply Off at the 39th. As I continue we will try to add names as we remember. 1958 started off with the usual projects with one exception -- the Labor Service Units of the Group were working on what would be the first Nike Ajax site in Germany. The site was next to the Rhine River in Karlsruhe Germany. (Dependent housing for all the 39th personnel stationed in Ettlingen was in Karlsruhe ). I may be confused on the year. I was still in the 77th and the 79th was given a classified mission requiring a full compliment of troops, no short- timers, no Jewish, and no middle easterners. I was called, told I would join the 79th for this mission and restricted to base. Sgt Maj Greer went to my dependent housing ( I neglected to say my wife joined me in the spring of 1957 after I returned from France) with instructions to get all my uniforms, including dress blues, and bring them to base. I loaded all my gear, including extra fatigues, in a locker box and took it with me to the 79 th the next day. I ended up on C Co with 1 st Lt Ken Halleran as our CO. Officers and enlisted from every U.S. unit in the Group were used to fill all the open slots in the Battalion, as well as all necessary equipment for full TO&E allowances. We had a lot of integrating to due since all units were about 80% in those days. Before we departed Pirmasens we sent trucks from each company to a general depot and loaded up with plywood sheets and salvage hospital ward tents. The tents and plywood were distributed throughout the convoy. We convoyed to Bremerhaven to load all equipment aboard ships. When we arrived we were told that the cab shields of the dump trucks were too high and they would have to go. We torched off all the shields and dropped them in the beds. Once all the equipment was loaded we boarded a U.S. troop ship, the USNS Eltinge (sp). A contingent of each unit sailed on the cargo ships. We sailed for our unknown destination. Actually we all knew that Syria had threatened to attack Lebanon and oust the president, so we knew generally where we were headed. The battalion went to Beirut; B Co went to Adana , Turkey. Our equipment caught up over the next week and everyone was engaged in offloading and setting up a base for the unit. Before we arrived the Syrians backed off, so we made a peaceful landing. We were told that some of the infantry units which came in amphibiously were met on the beach with Coca-Cola stands. We went to work settling in: The army can hurry to get you there but take their own sweet time getting you back home. One of our initial jobs was picking up garbage; there had been no pick-up for several weeks and the streets were so full we had trouble getting our heavy equipment through . We set up camp in an olive grove with pup-tents stair stepped up the terraced side of the valley. Meanwhile B Co. was busy setting up camp at Incerlik Air Base at Adana, Turkey with the mission to build an ammunition depot there. I was selected to sit on a Courts Martial board there so went there for a visit with other members of the board. Plywood and salvage hospital tents were like gold!!!! Greatest trading material in the encampment. Tents became Ordnance shops, supply storage units, and administrative support shelters --- all at a price! -- Mostly supply items, rations, or other comfort items. We found that our foreign aid program had furnished the Lebanese Army with the equivalent of a company of 5-ton dump trucks. All were sitting in a motor pool with blown clutches. Equipment without training is generally a waste; at least in this case .So we set up a school, actually two schools; one for drivers and one for mechanics. We prepared lesson plans, set up a buddy system to train each operator/mechanic and by the time we departed each vehicle was running. Cost us a couple of tents and a bunch of plywood but we found the necessary parts beyond what we found in their supply system. On the other side of the valley from our encampment was a Marine unit. Those guys travel light and are not meant for sitting in the field. We were eating B Rations by the light of our illumination sets and watching movies every night. The marines were eating cold C’s in the dark. We finally loaned them emersion heaters, a 5 KW generator set with illumination set so they could eat hot rations, have hot water, and see what they were doing. Truly inter service support. I want to go back to my assignment in the 275 DT Co. to record an incident that some might find interesting. The three platoons were split up over three construction sites near Heidelberg and the troops billeted in two separate casernes. In those days everyone was paid to the penny in cash each payday. An officer of the company was placed on orders as the Pay Officer; he would go to the Finance Office, armed with a 45 pistol, pick up the payroll in bulk, (but with the proper change to cover all payments ), take the money to the company area, and divide it up based on the payroll showing what is due each person. Usually each man’s pay was put in a separate envelope and no-one paid until the payroll balanced. If it didn’t balance then the Pay Officer had to make up the difference. In this particular incident I was the Pay Officer; I paid the people in the company area, then headed north in my POV to pay the soldiers on the projects. I took with me the company clerk to handle some collections, etc, as we went. Enroute to the second project site the clerk suffered an epileptic seizure. I changed plans and went at top speed to the local station hospital to get him treatment. I parked in the entrance to the ER and rushed him in to the ER. I realized I had left the remaining payroll and weapon in the unlocked car so I rushed back out, pushed down the buttons on the doors and locked it up. I had locked the keys in the car in my haste and there we sat. Extra keys were brought to me from home and all ended well for a very trying day. None of this would have happened with direct deposit checks, but no such luck in those days. So much for the way we paid every body in those days. Back to Lebanon – We were released after about 4 months; began loading equipment aboard ship, and went back to Germany as a unit. We unloaded everything in Bremerhaven and convoyed as a unit to Pirmasens. We then unloaded the 79th property and headed back to Ettlingen and Nellingen. We were all reassigned to our original units. We had been gone just long enough to disrupt the usual patterns of work, leave, and in some cases rotation to CONUS. We spent some time on repairing the units and getting everyone back on track. Very few projects were undertaken during the winter and most of the time was spent in unit and individual training. Early in 1959 I was reassigned again to B Co of the 79th on a permanent change of station. Capt Ambrose also was moved to B Co 79th. We began preparing the unit for deployment in France. B Co was assigned the task of building a 6-pad heliport and resurfacing the runway in a small strip in Verdun, France. The rest of the battalion was assigned several projects in the vicinity of Nancy, France. The US needed France as a fallback position in the Cold War in the event of a Russian attack. However it was too expensive to station US troops in France year round so we went to France during the “construction weather” and spent the rest of the time in Germany. The plan was for one battalion (the 79th) to go for 3 to 4 months and the other battalion (the 94th) follow and finish the projects started by the other. We would alternate being first each year. We headed for Verdun early in March and because the trip was short we made the move in two contingents without outside assistance. We settled into Verdun in an existing base and began work. The site required a large amount of fill to reach grade for the helipads. There was a large supply of a caliche like material near-by that was a by-product of a manufacturing plant. We used a mechanical shovel to excavate the material, and all of our dump trucks to haul. The material was dumped at the site, spread by dozers, and compacted by rollers. We watered the site if the caliche became too dry to compact and scarified the surface between layers. We reached grade and began to place the concrete helipads. First the forming, then placing and tying reinforcing steel. We mixed the concrete in a side loading mixer on site and poured directly into the forms. The rollers, mixer, water truck, and shovel were from the 175th HE Co. They were attached to us for the duration. We about ran out of time while placing the pads. We were to leave it to someone else to finish. Somehow Capt Ambrose talked the Group and Battalion into letting us finish the project. We were given two months to finish. We began a double shift operation and started the asphalt paving of the runway. Asphalt came from a French plant and the paver from the 175th HE Co. We figured that we needed to finish the project or whoever did would blame the base preparation for any surface problems or failures. We did the job with two days to spare. Meanwhile we had a big completion party for all the troops and began sending them back to Pirmasens as they were no longer needed. Within two weeks the company was completely reformed at Pirmasens and ready for the next projects.We had already used up a significant portion of the construction season, and began building sports plazas for our German neighbors as a good will gesture. We built soccer fields, combined tennis and basketball courts and restroom facilities where water and sewer were available. This continued through the end of the summer with a few unfinished projects to complete in the spring.We thought we were done for the year but we were wrong! B Co. had developed a reputation for good work on their own -- starting in France, separated from the battalion in Turkey, and again at Verdun. An emergency arose and we were called to meet the challenge again. Before I go to the next project I need to catch up on officers assigned to the 79th: Maj Sam Lurie XO; Maj Leroy Emshoff S-3; Lt Ed Humiston B Co; Lt Bobby Rice B Co; CWO#3 Watkins B Co; CWO 3 Ed Webb (replaced by Watkins) B CO; Lt Joe Yore A Co; M/Sgt Poretta 1 st Sgt B Co. Training involved the usual Marksmanship, First Aid, Safety, and classroom refreshers. We also trained for our missions in the event of an attack by the Soviets. Basically we were to fall back and set up positions as directed – even to the French coast if necessary. Each year we sent our heaviest and largest load on the evac. rout all the way to insure that the road remained clear. The load was a 5-ton dump truck with a 5th wheel dolly pulling a 25 ton semi trailer loaded with a D-8 dozer attached to a scraper in tow, one hell of a load for French roads. We made it every time. Back to my story -- Bitburg Air Base was in western Germany near the Luxembourg border. This was a tactical base supplying close air support to Army tactical units facing the Soviets. An underground river cut into the lake forming the base fire suppression reservoir and left them non-operational!! B Co. to the rescue. We were called to attempt to get them back operational as soon as possible. The weather was cold and wet; just plain miserable. Brigade Engineers had identified a water source some 9+ miles from the base. The source was an abandoned slate mine with a water level some 100 feet below grade. We went to work. We drew two 5-mile pipeline sets from depot, a submersible pump and about 150 feet of steel pipe . We connected the steel together, mounted the submersible on one end and lowered the pump down into the mine shaft. Meanwhile two platoons took a 5-mile pipeline set each and began stringing pipe along an existing forest cut from the mine to the closest fire hydrant on the base. Work on all phases went on 24 hours a day. When we had all together we set a booster pump (part of the pipeline set) at the top of our well and one at the 5 mile point, and pushed the switch. The base had water and was now operational!! Pretty good for ___ days work. One thing I should mention. The first night at the base the five officers of B Co. went to the Officers Club to get something to eat. Since we were in the field we were all in fatigues. The Club Officer immediately told us we were not allowed in in field clothes and asked us to leave, period! On the way out we encountered the Base Commander who asked if everything was OK and our CO explained the situation. The Base CO called the Club Officer and told him that these five Army officers were welcome in HIS club at any time they were open in any uniform they saw fit! The next day the Base Supply officer gave each of us a 100 foot and a 50 foot steel tape for our work and said keep them. I still have both and used them all these years. Needless the Air Force was grateful and expressed their gratitude as we left. The troops all thought we should get a medal but never happen. The winter passed and we were soon in 1960. Capt. Ambrose rotated out and was replaced by a Lt. Losser (sp?). We expected to be ready for a summer in France but not so fast! An earthquake struck the city of Agadier, Morocco, doing massive damages. Since we had five air bases in Morocco it looked like a good idea to help. Group Headquarters decided to form a task force under a Col from the HQ. and B Co, again was called and we headed out. All selected and necessary equipment was ferried to Landstuhl Air Base and loaded in C-130 transports. And the four D-8 dozers were loaded in C-124’s. Incidently only two arrived; one emergency landing in Spain and the other at a base in Morocco. We got by without them. We assisted in moving bodies with dump trucks and leveling structures with dozers. We were too late for any recovery activities. We continued to assist the Moroccan Army as they requested until the situation was in hand, and we began flying equipment and personnel back to Germany. It had taken about two weeks to get everything there and almost a month to return all to Pirmasens. I was on the last plane going and last returning since I had taken a loadmaster course years before but now was called to use it. I do not remember how long we were gone from Pirmasens since I spent a couple of weeks loading in Landstuhl. Returning to Pirmasens I found I had orders to rotate in June to the Presidio of San Francisco. I had to decide if I would accept these orders or request release from active duty. After some long discussions with my wife and several senior officers we decided to go to PSF and if unhappy I could get out after one year. ( I was in the zone for Captain and under consideration for Regular Army appointment.) Before I could get out of there B Co was hit again. A 100,000 gal tank of gasoline at the QM depot in Mannheim sprung a leak and dumped the full load on the ground. The berms prevented the spread of the fuel, but enough soaked into the ground to cause the local civilians to complain since it had gotten into the aquifer that supplies their water. We went up to Mannheim with truck mounted augers and drew some large sump pumps from the Depot there. We drilled down to the water table all around the tank and set pumps in the holes. The gasoline sat on top of the water and we were able to suck it out in about a week. Remember the Frenchman who ran into our semi-trailer the first summer (1957)? About May of 1960 we received a claim against the Battalion since we ran a stop sign and struck the Frenchman. They knew that a regular tour for us was three years so they would wait for a little over three years to file these claims assuming that all involved were gone home to CONUS. But I got him. I sent in a copy of my original report, my original color slides since I could not get copied in Germany in those days, and a follow up from the Battalion -- never heard another word. And I DEPARTED Germany in June 1960. |

||||||||||||||||||||

|

|

||||||||||||||||||||

| 291st Engineer Company | ||||||||||||||||||||

291st Engr Hvy Equip Co motor park on Daenner Kaserne, Kaiserslautern |

||||||||||||||||||||

| (Source: Email from Charlie Klopp, 291st Engr Co, 1950-52) | ||||||||||||||||||||

A PARTIAL HISTORY OF THE 291st ENGINEER HEAVY EQUIPMENT CO EARLY 1950 - SEPTEMBER 1952 AS REMEMBERED BY CHARLES KLOPP |

||||||||||||||||||||

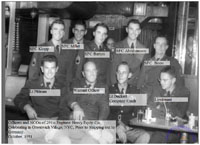

| EAU CLAIRE, WISCONSIN - EARLY 1950 My first connection to the 291st came in early 1950. I had just completed 12 months of active duty in the Army and now had 6 years of reserve obligation. I was assigned to the 291st and attended a number of monthly meetings. I was thourghly enjoying civilian life during the summer of 1950 when the North Koreans came across the line in late June. Shortly after that (July or Aug) our company was put on alert. In early September we were back on active duty. In the meantime, reservists from the upper northwest portion of Wisconsin had been added to the company’s roster. CAMP RUCKER, ALABAMA - SEPTEMBER 1950 Our company was moved to Camp Rucker, Alabama shortly after being activated. Camp Rucker had apparently been closed after WW2. The company area was overgrown with weeds and most of the barracks were in poor shape. Mostly steps and ladders. Our first mission was to cut the grass, which we did with pocket knives. We didn’t have much to do during the first months except to try and look busy. The army does not like to see people loafing. We had about 5000 troops at Rucker till early 1951 when the National Guard from Minnesota and the Dakotas moved in. After a bit we received a bunch of recruits and all of a sudden we were giving basic training to the troops. Not much happened for some time after that. Some went to schools, others worked on our equipment. Then, we got word that we were going to Germany. Also at this time we learned that we could go home after one year of active duty. Most of the NCOs from WW2 decided to go home. A number of us younger guys decided to go to Germany. In my case I had neither job nor girl friend to go home to and if I stayed another year I would have no further obligations for reserve duty and also could get full benefits of the GI bill. So, our outfit went to Germany. KAISERSLAUTERN, GERMANY - OCTOBER 1951 We left Camp Kilmer in New Jersey in October and crossed the North Atlantic under less than desirable conditions. Estimated 4000 sea sick troops on board. We arrived in Bremerhaven and were transported to Kaiserslautern in those old 40 and 8 rail cars. When we got to Kaiserslautern we were billeted in the Panzer Kaserne. This was deluxe living compared to the barracks we had back in the states. It was also convenient to down town Kaiserslautern. Our mission in Kaiserslautern was to excavate for what was to be the largest Engineering Depot in the world. That’s what we were told. The reason for this was as follows. After WW2 we thought the war was over. Then our problems with Russia started. Looking at Russia as a potential enemy, our people noticed that our supply depots were up at the front and the combat units in the rear. Thus the decision to build the depot on the French side of the Rhine River. Our company had a lot of earth moving equipment. D8, D7 and D6 Cats. 6 large motorized scrapers. (Le Tourneau’s) Trucks, scrapers, lo boys, etc. I believe we moved the first dirt for what was to become a large military installation known as “K-Town." KARLSRUHE, GERMANY - MID 1952 After completing our work in Kaiserslautern our company moved to Karlsruhe. I don’t recall much of what went on there or why we were there. Most of us were thinking of going home. This presented somewhat of a problem for the company. When the WW2 vets went home in 1951, more rank was needed to replace them. The 291st was unique in one respect. That was in the amount of rank we were authorized to have. Example – 5 or 6 Masters. 10 or 11 SFC’s. 63 Staff Sergeants. 92 corporals. (In 1950 corporals had same pay grade as 3 stripe buck sergeants in WW2.) Most of us younger guys who went to Germany had been promoted to SFC and Staff Sergeant. The same group was now going home. At least 90 percent of the companies NCO’s were leaving. We had some fantastic promises about promotion if we would stay. No one stayed. ATTACHMENTS: My favorite picture, see attachment, was taken in a bar in Greenwich Village in New York City. Just prior to embarking for Germany. It was for the most part the officers and NCOs that were to run the company in Germany. Also, I am attaching a few pictures to give some idea of the type of equipment we were operating. |

||||||||||||||||||||

| (Source: Email from Charlie Klopp, 291st Engr Co, 1950-52) | ||||||||||||||||||||

I happened to look up the 291st Eng Co and found your info request.

I was in the 291st Engr Co from Sep 1950 to Sep 1952. I had previously been in the Army from Jan 1949 to Jan 1950. My home town was Mondovi, WI. After my first stretch in the Army I was assigned to a reserve outfit in Eau Claire, WI. That was the 291st Engrs. I was enjoying civilian life to the utmost at that time when the North Koreans came across the line. By early Sep I was back on active duty.

The 291st was sent to Camp Rucker, Al. (Now Fort Rucker) For the first several months we mostly tried to keep busy. Then later on, perhaps early 1951 we got a lot of recruits and from then on we were busy training them. They stayed with our company.

In Oct of 1951 we received orders to go to Germany. We were stationed in Kaiserslautern. We found that our job, with our heavy equipment, was to excavate for an engineering depot. The reason was this.

After the war there was no particular concern about where the units were stationed. After the start of the Cold War, the military found that the combat units were stationed in the rear, in relation to the perceived enemy, with the supply units near the front. Combat units were moved to the front and supply depots to the rear. We were helping to build the largest engineering supply depot in the world.

After our work was done in Kaiserslautern we were shipped to Karlsruhe. I don't recall much about that time. We were fortunate in one respect in that we were occupiers. Shortly after we left Germany the occupation came to an end. What this meant was that army had jurisdiction during the occupation and the Germans had it after the occupation ended.

I was a part of a group of non-coms that came home in Sep of 1952. Our First Sergeant at that time was Master Sergeant Engebretson and he decided to stay.

I have a picture of the group of officers and non-coms that originally went with the company to Germany. If you are interested I can attach it to another e-mail.

|

||||||||||||||||||||

|

||||||||||||||||||||

| (Source: Email from Joe McKnight, son of Alvin Clyde McKnight, former member of 291st Engr Hv Equip Co) | ||||||||||||||||||||

|

||||||||||||||||||||

I always knew he had a picture or two from those days. But, after his death, we kept finding more pictures. I’m not certain yet that all of them have been located. There may still be a shoebox or two stuck away in a closet! My hope is that one of his old buddies, or a family member, will find these pictures and enjoy them as much as I do! |

||||||||||||||||||||

|

||||||||||||||||||||

| 1955 | ||||||||||||||||||||

| (Source: Email from Ed Bocko, 291st Engr Co, 1955) | ||||||||||||||||||||

| I ran across

you site outlining the work done at Fuessen, Germany with respect to

the schooling. I was stationed at Rhineland Kaserne near Ettlingen, Germany in 1955 with the 291st Engineer Co, HC. I was an F & E specialist in the ordnance maintenance section so I was selected to take additional training at Fuessen late in the year. It was beautiful and I spent Christmas with a German family which was one of the nicest holidays I ever had. I am in the process of trying to locate members of the 291st Engineer Co. (part of 39th Engr. Group) which was later changed to the 175th Engineer Co., HC. I found the 175th history and web site, but it is only post Viet Nam. I have hit brick wall after brick wall with little or no results. The 291st Engineer Co., HC, was billeted in the same building as the 77th. The 291st later became the 175th. I believe the 77th was retired sometime in the 60's, but I'm not sure. I'm send this note to a couple of guys that I have contact with and maybe they can enlighten you some more. The only guy I specifically remember was a short guy from CA whose name was Joe Stecker. Joe was a windmill style softball pitcher for the 77th, but he hung out with us more that the 77th. Incidentally, the 291st built the Ordnance Depot at Mannheim and the Engineering Depot at Kaiserlauten. Also, I was involved in moving heavy equipment to Nancy and Metz, France where more depots were built. Also, the 39th Group was changed to the 75th Group and did some outstanding work in Viet Nam. Ed Bocko ADDITIONAL INFORMATION (added Oct 14, 2005) I arrived in Europe in March 1953 aboard the troopship George W. Gothels and left in July 1956, returning to the States on the General Harry Taylor. As I understand it, the 291st was "attached" to the 39th Group but not totally subject to it. Col. Nolting was the 39th commander and at Rhineland, the only units were the 291st Engineers, 77th Engineers, a Dump Truck Co. (can't recall the number), Headquarters Company (39th Gp) and several Labor Service Groups. I do not recall the units you mention on your site and the only one I can remember was the 555 Combat Engineers at Smiley Barracks (Triple Nickle) During WW II, the 291st was a batallion commanded by Major Pegram (excuse spelling) and really distinguished itself at the Battle of the Bulge. The German General Piper could not cross any rivers because the 291st checked his tanks at every bridge. At his post-war trial, he put his hands on his head and said, "Those damn engineers..." After the war, the 291st was instrumental in building depots at Kaiserslautern, Mannheim, Nancy, Metz and Toul in France. Most of the equipment operators were on TDY during the summer with jobs all over the place. I think it was late 1955 when the 291st colors were retired and the unit was redesignated as the 175th Engineer Co. Heavy Construction. When I arrived, the company commander was Capt. Gorman who was succeded by 1st Lt. Dorman. Officers included Lt. Richmond, CWO Ylikopsa (Ordnance) and WOJG Parker (Engineering) I am really interested in learning more about this entire group and it's history. I checked your roster but none of the names are familiar to me except Meeks. We had a fellow from Wisconsin named Meeks. |

||||||||||||||||||||

|

|

||||||||||||||||||||

| 620th Engineer Company | ||||||||||||||||||||

| (Source: Email from Charles Baileys) | ||||||||||||||||||||

| I was an enlisted member of the 620th Engineer Company from Feb 1959 thru July 1962. We provided repair and overhaul on all equipment for the 39th Engr Gp. We were stationed at Gerszewski Barracks, Karlsruhe. At that time the units I remember being at Gerszewski Barracks were the 18th Ord Det, the 25th Sig Bn, a Nike Herc DSP and a Medical det. I continued my military career with assignments with the 864th Engr Bn (Const) at Camp Wolters, Tx and a tour in Korea with the 44th Engr Bn. I retired at Fort Bliss TX as a CW3 in 1978. Would enjoy hearing from former members of the 620th. |

||||||||||||||||||||

| (Source: Email from Robert Hill) | ||||||||||||||||||||

| I have been browsing the 7th Eng Bde website, and have not seen anything about my old unit. The 620th Engr Co (Field Maint) was the DS maint unit for the 7th Bde. Our unit hdgs was the 39th Eng Group. I was assigned to the 620th from 1 Jan 1960 to 7 May 1962. In Jan 1960 the unit was under the cmd of COMZ. In early 1960 we were placed under USAREUR. Not sure about TOE but I do know we had 3 maintenance platoons and a headquarters platoon. So I'm guessing the authorized strength was about 120-130 pers. The unit was located at Gerszewski Barracks just outside of Karlsruhe. The unit's mission was to provide level 3 maint of the bde engineer equipment. Each maint plt was authorized a contact truck to provide maint on the job sites. The unit had a contact truck on the road at all times. They were generally TDY for 30 days and they covered most of Germany. Most of the job sites back then were (Webmaster: NIKE) missile sites. The company commander at that time was Capt Malcolm Stricklan and the 1st Sgt's name was Hill. The 620th also maintained a float pool of equipment. If a unit needed an additional dozer or grader we would issue it on a short time issue, or issue a piece of equipment while theirs was being repaired. They also had a maint contact team located in Kaiserslautern to support the 24th Gp. The team consisted of one E-5, two E-4's, and one E-6 or E-7. I have attached some photos. All personnel are members of the 3rd maint pltn. |

||||||||||||||||||||

|

||||||||||||||||||||

| Related Links: |

||||||||||||||||||||