If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany'

frameset |

66th Maintenance Battalion

21st Support Command

Looking for more information from military/civilian

personnel assigned to or associated with the U.S. Army

in Germany from 1945 to 1989. If you have any

stories or thoughts on the subject, please contact me . .

|

|

|

|

|

|

| 66th

Ordnance Battalion |

| |

66th Ordnance Bn DI (not

sure if this was worn in Germany)

66th Ordnance Bn DI (not

sure if this was worn in Germany) |

| |

| Source: AN&AFJ,

24 Sept 1955 |

The following

battalions are scheduled to exchange duty stations next spring and

summer as part of Operation Gyroscope:

ORDNANCE

66th Ord Bn, Ft. Bragg, NC will replace the 80th Ord Bn, Stuttgart

|

|

| |

(Source: Seventh

Army Annual Historical Report, 1958)

ORGANIZATION (as of 30 June 1958): |

|

UNIT

DESIGNATION

|

DUTY STATION |

COMMENTS |

| HHD,

66th Ord Bn |

Knielingen

[1] |

|

| 150th

Ord Det (IFCR)(M-33) |

Wiesbaden

[1] |

|

| 151st

Ord Det (IFCR)(M-33) |

Mannheim

[1] |

|

| 152nd

Ord Det (IFCR)(M-33) |

Kaiserslautern

[1] |

|

| 169th

Ord Det (IFCR)(T-38) |

|

|

| 183rd

Ord Det (IFCR)(T-38) |

|

|

| 223rd

Ord Det (IFCR)(T-38) |

|

|

| 370th

Ord Det (IFCR)(T-38) |

Mannheim

[1] |

supporting

7th AAA Bn? |

| 371st

Ord Det (IFCR)(T-38) |

Wiesbaden

[1] |

supporting

443rd AAA Bn? |

| 14th

Ord Co (Dir Spt) |

Wiesbaden

[1] |

|

| 18th

Ord Co (Dir Spt) |

Knielingen

[1] |

|

| 531st

Ord Co (Dir Spt) |

Mannheim

[1] |

|

| 546th

Ord Co (Dir Spt) |

Kaiserslautern

[1] |

|

| |

|

|

|

| [1] STATION LIST,

17 April 1957 |

| |

| At this time,

the 66th Ord Bn was part of the 51st

Ord Group. |

| |

If you have more

information on the history or organization of the 66th Ord Bn or the

66th Maint Bn, please contact me . . |

|

|

|

| 66th

Maintenance Battalion |

| |

66th Maint Bn DUI

66th Maint Bn DUI |

| |

| (Source: STARS & STRIPES, March 15, 1967) |

Members of the 66th Maintenance Battalion have recently received their new unit crest which was designed by Capt Clarence R Mills and Sgt Maj John Daugherty (Ret.).

The design was approved by the Institute of Heraldry on February 8, 1966. |

|

| |

| COSTAR II (Combat Service to the Army) |

| |

| If you have corrections, comments and additional information/photos please contact the webmaster! |

| (Source: STATION LISTS for 1964 an 1965; FM 29-22 Maintenance Operations in the Field Army, July 1965) |

| In 1965, the 66th Ordnance Battalion (Maintenance and Supply) (TOE 09-076D) at Rhine Ordnance Barracks, Kaiserslautern, was reorganized under the COSTAR II concept. The battalion was redesignated as the 66th Maintenance Battalion (Direct Support). |

|

| ORIGINAL UNIT |

NEW UNIT |

STATION |

COMMENTS |

| HHD, 66th Ord Bn (M-S) |

HHD & A Co, 66th Maint Bn (DS) |

Rhine Ord Bks, Kaiserslautern |

|

| 546th Ord Co (DS) |

(A Co (Main Support)) |

|

|

| 68th Ord Co (DS) |

B Co (Lt Maint) |

Pulaski Bks, Kaiserslautern |

|

| 48th Ord Co (DS) |

C Co (Lt Maint) |

Smith Bks, Baumholder |

|

| |

|

|

|

|

|

| |

| 1965 |

| (Source: Email from Joseph Creati) |

| Webmaster note: Joe is researching and compiling a comprehensive unit history of the 66th Ordnance/Maintenance Battalion for the time frame February 1965 - April 1968, and will provide additional information on the role and history of the Battalion as he collects further details on the unit and its subordinate elements. Joe welcomes any/all feed-back/comments regarding his experiences/recollections. He is also very interested in re-connecting with those who served there in the same time-frame and who shared similar growth experiences at the 66th Ordnance/66th Maintenance Battalion. You can email the webmaster who will forward your emails to Joe. |

| |

|

|

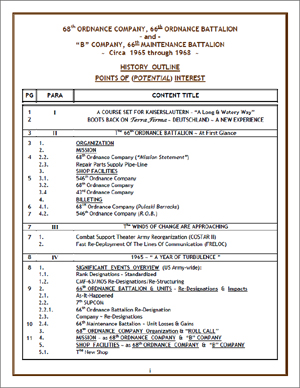

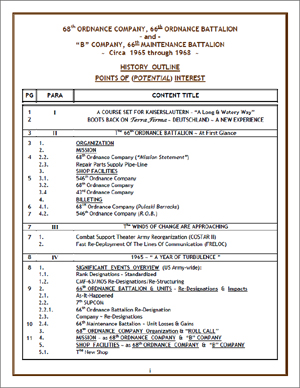

Click on the image on the left to read Joe's UNIT HISTORY:

"68th Ordnance Co., 66th Ordnance Bn. Re-Flag to “B” Company, 66th Maintenance Bn. A History 1965 through 1968."

The file is about 600 Kb and in Adobe PDF format (Abobe Reader is required to view the file).

Joe looks forward to any suggestions and feedback and invites former members to provide any additional unit information that will help expand on the unit's history and accomplishments.

Thanks, Joe! Great job on the research and compilation of this unit history!

Walter Elkins (webmaster,usarmygermany.com)

|

| |

|

|

|

|

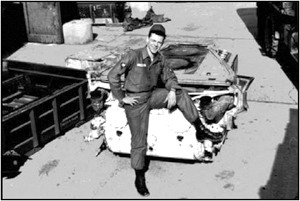

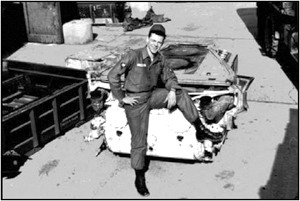

Click on the photo on the left to view Joe's Photo Gallery.

The file is about 1 Mb and in Adobe PDF format (Abobe Reader is required to view the file).

Photo: Sp4 J.A. Creati at the new "B" Company (66th Maint Bn) shops |

|

| |

| I’ve just reviewed the article that was allegedly extracted from the “Seventh Army Annual History, 1965” which, therein, attempted to document the creation of new commands, deactivation of selected units, and re-organization/re-designation of other units through COSTAR II. I found major components of that information to be not necessarily true or accurate – at least not for the Ordnance (maintenance) units within the 7th Army and those “troops on the ground” who lived through that period and were involved with all aspects of that ever-changing and extended experience. I can only surmise that the information presented in the article was gathered from the “paper Army” as perceived/projected and organized through the idealistic planned construct which was envisioned by the [overly] optimistic implementing “forces” at “higher headquarters”.

Yes, the Seventh Army Support Command (7th SUPCOM) was established in 1965, but was not long-standing for those 7th Army Ordnance (maintenance) units. It took a while for the SUPCOM to gain its “footage”, but by the time it did, the 7th SUPCOM was superceded [in “our” chain-of-command] by another re-organization which established the 1st and 2nd Support Brigades which took direct command of those Ordnance (maintenance) units which were under the 7th Army (previous to 1965). “Our” [my] battalion was re-organized under the command of the 1st Support Brigade.

Implementation of and establishing the desired results of COSTAR II had a very slow/delayed start which resulted in a cascade-effect that created “skip-step” hesitation among the effected subordinate units. Stabilization took time. As we experienced the ripple of change . . . “one day” our unit was under the 7th Army, the “next day” we were supposedly under the 7th SUPCOM, and “a couple of months later” we were under the 1st Support Brigade.

I especially have to take exception to the “Letter from DCSPER to CINCUSAREUR, 8 May 1965”. That could have only been a DRAFT concept. I’m focusing my attention to “Paragraph 7” of that letter. Many of those cited changes, re-organizations, and re-designations did NOT happen as listed [planned].

I was a member of the 68th Ordnance Company, 66th Ordnance Battalion, with sister companies including: the 546th Ord. Co.; 48th Ord. Co.; and 43rd Ord. Co.. None of those changes occurred as indicated within the referenced “Paragraph 7”. The time-table conflict - it wasn’t until late 1966 or early (Spring) 1967 that COSTAR II affected our battalion in two measurable ways.

First – our battalion came under the command of the 1st Support Brigade (headquartered, at that time, in Mannheim).

Second – our battalion and [retained] companies were redesignated, as follows:

66th Ord. Bn. = redesignated 66th Maintenance Battalion (not the 19th Maint. Bn. as suggested/listed); all our sister companies stayed within the current battalion organization, except one – the 546th Ord. Co. = redesignated A Co./66th Maint. Bn.; 68th Ord. Co. = redesignated B Co. (DS/GS)/66th Maint. Bn.; and the 48th Ord. Co. = redesignated C Co. (DS)/66th Maint. Bn..

Additionally, our newly redesignated battalion acquired two new units which included the 508th CC&S Company and the 171st Support Platoon.

“Our” loss - the 43rd Ord. Co. stayed in “K-town”, but reverted to the command of another [redesignated] maintenance battalion – I believe either the 51st or 71st Maintenance Battalion(s), both located in Mannheim.

During this “growing period” (1966-1968), the 66th Maintenance Battalion experienced many dynamic changes and my company, especially, B Co./66th Maint. Bn., was growing exponentially in manpower/personnel, ranges of MOSs, expanded capabilities of shop mission/support and operations, increased numbers of unit vehicles/equipment, SKOs, and facility support equipment, to name a few. In short, “our” company’s new M/TO&E, under {assumed] COSTAR II and the 1st Support Brigade, had “exploded” in gigantic proportions.

This is merely the “tip of the ice berg” on this historical subject. I’m presently involved in recounting and documenting the history of the 68th Ordnance Company, 66th Ordnance Battalion and the [later redesignated] B Company (DS/GS), 66th Maintenance Battalion (circa 1965 through 1968) to fill open holes which apparently exist in [other documented] areas of the 7th Army (Cold War) history.

I hope this clarifies some of the misrepresentations stated in the article cited and, further, assist the 7th Army (Cold War) Historian in recovering [some of] the details of that time from those who “were there and lived it”.

66th Maintenance Battalion motto: “PRIDE IN SERVICE” . . . always and ever . . .

ADDITIONAL INFORMATION:

|

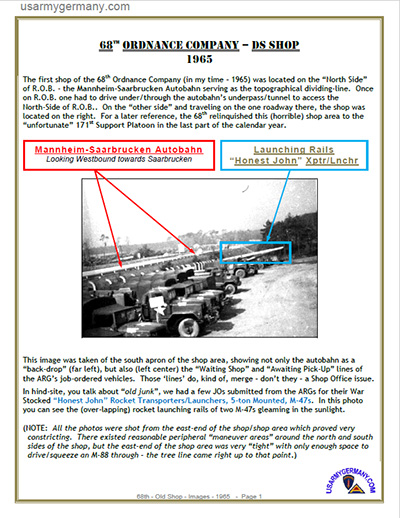

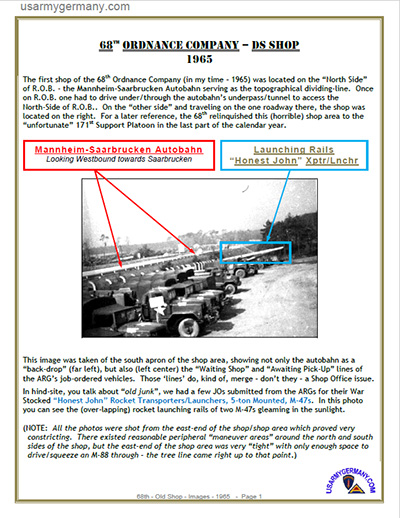

Short report on the set up of the

Direct Support

Shop, 68th Ord Co, Kaiserslauterm

Click on image to read the report (PDF file) |

|

| |

| 1968 |

| (Source: Email from Gary Hutchinson) |

I stumbled across this web site, looked up 1st Support Brigade and found the 66th Maintenance Battalion. I was in the 171st Ordnance Platoon. It was not a company but a platoon. The 66th provided direct support to the 3rd Armored Cavalry (Regiment). We were attached to the 66th and provided direct support to the 1st, 2nd and 3rd squadrons, 3rd Armored Cav.

We were a platoon of mechanics and helped to keep the cav running. In 1968, a troop reduction was ordered, the first Project Reforger was organized at that time and the 171st was detailed to help inspect and repair all of the Cav's vehicles through the turn in process and storage. The 3rd Cav was reassigned to Fort Lewis Washington, the 171st Ordnance Platoon was reassigned to MacGregor Range in New Mexico. Headquarters was at Fort Bliss, Tx. We ended up working on missles of all things. There was talk of us beginning work on the first Vulcan-Chaparral equipped tank. The Vulcan was a machine gun that fired about 4000 rpm and the Chaparral was a missile. I got orders for Nam and departed in Dec 68.

I have stayed in touch with only 1 person from the 171st and ran into 1 sgt from the 66th and another guy from the 171st but that was years ago. I remember the feeling of despair when I got to the 1st Support Brigade HQ in Mannheim. I was stuck in an attic for 2 days till I got orders for Kaiserslautern ("K-Town", as we called it). I was put in the back of a 3/4 ton with a canvas cover and driven to K-Town in the dead of winter and it was snowing. There was room up front but the jerks wouldn't offer to let me ride up front with them.

I got to Rhein Ordnance Barracks ("R O B"), which was a former Nazi barracks (Caserne) and was placed in a room with 7 other guys. Our view was of the parking lot and the Opel plant next to us. It was a shock for an 18 yr old kid that had never been outside of Indiana. I remember it like it was yesterday and would not like to live it again. |

|

| |

| 1969 |

| (Source: Email from John Ballard, 538th Maint Co, 1969- ) |

| ORGANIZATION (1969): |

UNIT DESIGNATION |

DUTY STATION |

COMMENTS |

| HQ & Co A, 66th Maint Bn |

ROB, Kaiserslautern |

|

| Company B |

Kleber Ksn, Kaisersl . |

|

| Company C |

Baumholder |

|

| 508th Maint Co (CC&S) |

Pulaski Bks, Kaisersl. |

|

| |

|

|

|

|

|

| 1969 |

| (Source: Email from Joe McGuire) |

I was assigned to the 66th Maintenance Battalion (Hq and Company A) at Rhine Ordnance Barracks in Kaiserslautern sometime in the spring or summer of 1969. This was after a brief stint at the 43 Heavy Equipment Maintenance Co., which had won some major maintenance award (the Big M???) a few months before I got there but did not seem to have an actual mission apart from keeping everything ready for inspection.

I was the shop officer at Hq and Co A. Company A was a direct support unit, providing both repair and repair parts support and was quite busy.

My recollection of what other units were at ROB then is foggy, except I recall that a Labor Service unit on the post ran a junkyard (probably called a Collection classification & Salvage Unit). I recall them vividly because we relied heavily on them for a lot of serviceable components where new ones in the supply system were nearly impossible to get. I recall that the company commander of this LS outfit was CPT Harry Jahn.

I inherited a backlog of over 100 military vehicles “awaiting parts.” Many had been sitting there for well over a year, and there two or three that had been there for two years. It took a few months to fix them all.

I was later transferred to the Battalion staff. I left the Army in September 1970 and returned to college majoring in German.

I recall that the NCO for the shop operation was Wesley Beach. A warrant officer named Frank ___ ran the supply operation. The First Sergeant was named Bell. I ran into one trooper some years later in law school.

I also recall watching the 1969 moon landing at the ROB Officers Club. Most officers and NCOs lived in the Vogelweh complex but I ended up with an apartment in Kaiserlautern. |

|

|

| (Source: Email from John Ballard, 538th Maint Co, 1969- ) |

(John has also provided comments on his assignments to Co "D," 71st Maint Bn and the 504th Sig Bn).

I returned to Germany in December 1969. I was on a DA assignment as a 76X (not my MOS but related) and was suppose to be going to Nuernberg. However, the powers that be sent me to V Corps instead of VII Corps; I was given orders to the 1st Support Brigade in Mannheim. When I arrived in Mannheim, I stayed over night and was further assigned to the 66th Maintenance Battalion at Rhein Ordnance Barracks (ROB) in Kaiserslautern.

The Battalion consisted of HQ & Company A at Rhein Ordnance Barracks, Company B that was located in Kleber Kaserne, Kaiserslautern, Company C located in Baumholder and the 538th CC&S Company at Pulaski Barracks (with shops and tech supply on ROB).

When I got to the 66th Maintenance Battalion I was further assigned to the 538th Collection, Classification and Salvage Company. The acting First Sergeant was SFC Milton Winters. My first duty position was NCOIC of the Cannibalization Yard. One of the funniest sights that I saw while working there was in one of the far back lots; there were three really large anchors for ships and nobody knew when or how they got there. This lasted for a few months until I agreed to help the Company get their Re-enlistment records ready for the coming AGI. I was supposed to return to the “junkyard” after the AGI but I had done such a good job they kept me there.

In June of 1970 I was attached to Battalion S-3 (and later re-assigned to Hq & Co. A) and assumed the duties of Battalion Training NCO. This position lasted for two years. During that period I received several commendations. I also participated in three REFORGER exercises. We had maintenance responsibilities for all pre-positioned Wheel and Tracked Vehicle equipment as it moved between Landstuhl and Hockenheim. I drove a radio jeep between Vogelweh and Mannheim many times a day reporting vehicles that were broken down along this route. I received a TASCOM Certificate of Achievement for this mission.

We had a radio relay site on a hill about half way between Vogelweh and Mannheim. I don’t remember which year that it happened but one day I stopped at the relay site to do something and while I was there a Canadian jet missed our van by about 150 feet then crashed up the hill from the van.

During 1971 we converted from the M-14 Rifle to the M-16 Rifle. Everyone had to go to the rifle range in Baumholder to qualify on the M-16 and we could not turn in the M-14’s until everyone qualified on the M-16.

In June of 1972 since we had an extreme shortage of 76P NCO’s in Hq & Co. A, I was reassigned to Tech supply. The Platoon Sergeant was my former First Sergeant, SFC Winters. He assigned me to the Direct Exchange Point. I discovered that the stockage list of items in the DX point had about 70 items on it that were not authorized by the 7th Army Stockage List so I set about removing them from the DX Point. This resulted in a tremendous savings to the Army.

The 66th Maintenance Battalion (DS) was previously the 66th Ordinance Battalion (I believe) and prior to that it was the Ordnance Company that invented the device that was mounted to the front of tanks during WWII that enabled them to break through the hedge rows. The 66th Maintenance Battalion (DS) had a Battalion award named after that device called the Guisarme Sable. If your service in the Battalion was Meritorious you were awarded this certificate and I received this award. |

|

| |

| 1976 |

|

(Source: Annual Supplement to the Unit History, 1 Jan 1976 - 31 Dec 1976)

|

|

HEADQUARTERS

66TH MAINTENANCE BATTALION (DS)

APO 09227

|

|

|

|

AERBB-A

SUBJECT: Annual Supplement to the Unit History

Commander

US Army Center of Military History

Washington, DC 20314

Commander

USAREUR

ATTN: AEAGB-MH

APO New York 09403

Commander

21st Support Command

ATTN: AERSP-O

APO New York 09325

1. References:

a. AR 870-5, Chapter 9. a. AR 870-5, Chapter 9.

b. USAREUR Suppl 1 to AR 870-5. b. USAREUR Suppl 1 to AR 870-5.

2. The following report is for the period 1 January 1976 thru 31 December 1976.

a. Organization: The 66th Maintenance Battalion underwent another major reorganization/civilianization. The 91st Maintenance Company (Collection, Reclamation and Exchange) and the 43rd Maintenance Company were inactivated on 20 June 1976. The 8903rd Civilian Labor Group and the 8907th Civilian Labor Group were organized and activated on 1 April 1976. The 8901st Civilian Labor Group (Automotive Overhaul Support) was redesignated as a Maintenance General Support (Collection, Recovery and Evacuation) unit, while keeping the same numerical designation, on 1 April 1976. a. Organization: The 66th Maintenance Battalion underwent another major reorganization/civilianization. The 91st Maintenance Company (Collection, Reclamation and Exchange) and the 43rd Maintenance Company were inactivated on 20 June 1976. The 8903rd Civilian Labor Group and the 8907th Civilian Labor Group were organized and activated on 1 April 1976. The 8901st Civilian Labor Group (Automotive Overhaul Support) was redesignated as a Maintenance General Support (Collection, Recovery and Evacuation) unit, while keeping the same numerical designation, on 1 April 1976.

b. Personnel Changes: As a result of the civilianization/reorganization the Battalion assigned strength decreased from 1622 on 31 December 1975 to 1554 on 31 December 1976. Approximately 50% of the Battalion personnel strength is now civilian. LTC Jerry N. Lindsay remained the Battalion Commander throughout the reporting period; CSM Leland Ellison remained the Battalion Command Sergeant Major. Major, then Captain, Michael E. King relinquished command of HHD to CPT James E. Birkhimer on 1 December 1976; CPT David W. Taylor relinquished command of the 5th Maintenance Company to CPT James G. Arnold on 28 December 1976; CPT Paul J. Hirt, Jr. relinquished command of the 546th Maintenance Company to CPT Kenneth H. Hayes on 16 December 1976; Major Chester W. Witczak assumed command of the 593rd Supply and Service Company on 20 June 1976 from CPT Timothy G. Eley, who served as acting commander from 16 January 1976; ZB-9 (Major, LS) Werner Jung assumed command of the 8903rd Civilian Labor Group, as its first commander, on 16 May 1976; and, ZB-9 (Major, LS) Edmund Midleja assumed command at the 8907th Civilian Labor Group as its first commander, on 16 May 1976. b. Personnel Changes: As a result of the civilianization/reorganization the Battalion assigned strength decreased from 1622 on 31 December 1975 to 1554 on 31 December 1976. Approximately 50% of the Battalion personnel strength is now civilian. LTC Jerry N. Lindsay remained the Battalion Commander throughout the reporting period; CSM Leland Ellison remained the Battalion Command Sergeant Major. Major, then Captain, Michael E. King relinquished command of HHD to CPT James E. Birkhimer on 1 December 1976; CPT David W. Taylor relinquished command of the 5th Maintenance Company to CPT James G. Arnold on 28 December 1976; CPT Paul J. Hirt, Jr. relinquished command of the 546th Maintenance Company to CPT Kenneth H. Hayes on 16 December 1976; Major Chester W. Witczak assumed command of the 593rd Supply and Service Company on 20 June 1976 from CPT Timothy G. Eley, who served as acting commander from 16 January 1976; ZB-9 (Major, LS) Werner Jung assumed command of the 8903rd Civilian Labor Group, as its first commander, on 16 May 1976; and, ZB-9 (Major, LS) Edmund Midleja assumed command at the 8907th Civilian Labor Group as its first commander, on 16 May 1976.

c. Mission: The 66th Maintenance Battalion is responsible for providing supply and direct and general maintenance support, and limited field services, within the western portion of the 21st Support Command area of responsibility. Because this mission is so vast and diverse, a summary of missions by unit will be presented in this area. c. Mission: The 66th Maintenance Battalion is responsible for providing supply and direct and general maintenance support, and limited field services, within the western portion of the 21st Support Command area of responsibility. Because this mission is so vast and diverse, a summary of missions by unit will be presented in this area.

(1) HHD - Composed of personnel assigned to the Battalion Headquarters; supports the mission requirements of the Battalion Headquarters. (1) HHD - Composed of personnel assigned to the Battalion Headquarters; supports the mission requirements of the Battalion Headquarters.

(2) 5th Maintenance Company - In the maintenance area, the company completed an average of 200 jobs per week while maintaining an average backlog of only 218 jobs. During the months of April and May the unit re-located its maintenance facilities from Rhein Ordnance Barracks and Kleber Kaserne to Panzer Kaserne and ESCK area on the east side of Kaiserslautern. During this period the company's living quarters were also moved to Daenner Kaserne. The move was completed without interuption to support our 105 customer units. On 1 JuIy 1976, this unit assumed the Direct Support repair mission of fuel and electric items from the 91st Maint. Co. During August 1976, customer technical assistance teams were provided to supported units to answer questions and provide assistance to maintenance problems concerning wheel vehicle, generator equipment, supply problems, and TAMM's procedures. Supported units readiness has improved due to the technical assistance provided. In the supply area, due to re-location of Air Force and Army units, this unit's supply support activity has an increase in customers from 95 to 138. During April 1976 this SSA underwent a major internal change of requisitioning procedures with the implementation of PUDS/DODAAC. Under this new system unit document numbers are perpetuated on supply passing actions to higher supply sources, instead of creating a document number by this SSA for supply passing actions. High Priority requisitions are usually passed to a higher percentage of customer satisfaction. During this year, the SSA processed approximately 82,000 supply requests, which include PEMA secondary items, direct exchange repairables and ASL/NSL items. This SSA maintained an average of 4,100 line items, 325 DX/DXW lines, and 60 PEMA items. This SSA maintained an average of 70% demand accommodation and 85% demand satisfaction during the year. In September and October 1976 the supply support activity conducted a cyclic inventory. This was the first time that such an inventory had been used. In the past years, complete shut-down wall-to-wall inventories were conducted with little support to customers during inventory periods. The results of the cyclic inventory were well within established goals of the 21st Support Command. The SSA actively engaged in Reforger 76 by operating a 24 hour basis and providing transportation of critical repair parts to troops in Belguim and Holland. (2) 5th Maintenance Company - In the maintenance area, the company completed an average of 200 jobs per week while maintaining an average backlog of only 218 jobs. During the months of April and May the unit re-located its maintenance facilities from Rhein Ordnance Barracks and Kleber Kaserne to Panzer Kaserne and ESCK area on the east side of Kaiserslautern. During this period the company's living quarters were also moved to Daenner Kaserne. The move was completed without interuption to support our 105 customer units. On 1 JuIy 1976, this unit assumed the Direct Support repair mission of fuel and electric items from the 91st Maint. Co. During August 1976, customer technical assistance teams were provided to supported units to answer questions and provide assistance to maintenance problems concerning wheel vehicle, generator equipment, supply problems, and TAMM's procedures. Supported units readiness has improved due to the technical assistance provided. In the supply area, due to re-location of Air Force and Army units, this unit's supply support activity has an increase in customers from 95 to 138. During April 1976 this SSA underwent a major internal change of requisitioning procedures with the implementation of PUDS/DODAAC. Under this new system unit document numbers are perpetuated on supply passing actions to higher supply sources, instead of creating a document number by this SSA for supply passing actions. High Priority requisitions are usually passed to a higher percentage of customer satisfaction. During this year, the SSA processed approximately 82,000 supply requests, which include PEMA secondary items, direct exchange repairables and ASL/NSL items. This SSA maintained an average of 4,100 line items, 325 DX/DXW lines, and 60 PEMA items. This SSA maintained an average of 70% demand accommodation and 85% demand satisfaction during the year. In September and October 1976 the supply support activity conducted a cyclic inventory. This was the first time that such an inventory had been used. In the past years, complete shut-down wall-to-wall inventories were conducted with little support to customers during inventory periods. The results of the cyclic inventory were well within established goals of the 21st Support Command. The SSA actively engaged in Reforger 76 by operating a 24 hour basis and providing transportation of critical repair parts to troops in Belguim and Holland.

(3) 43rd Maintenance Company. - The reporting period is 1 January 1976 to 20 June 1976. The unit received 1267 work orders during the report period and completed 1903 work orders. The average work order completion rate was 380 work orders and a month backlog of 650 work orders was maintained. During May the transfer of work orders to the 8903rd CLG Co which is scheduled to assume the mission of the 43rd Maintenance Company was begun. A total of 526 open job orders was transferred during May to the 8903rd and the 43rd Shop office was closed out effective 28 May 1976 with the transfer of the last 28 work orders to the 8903rd CDG Co. As a result of the inactivation, the unit transferred its mission responsibility in all commodity areas starting the 10th of May with Shop Supply and Light Engineer platoon and concluding with the Commel platoon on 15 June 1976. Mission Shop space formerly utilized by the unit was realigned between the 5th Maintenance Company, ESC-K and 8903rd CLG Co. Bldg 3047, ESC-K which housed the 43rd Shop Office, Shop Supply, Heavy Engineer Equipment Repair Section, Automotive Repair Section, and Service Section was turned over to the 5th Maintenance Company. Bldg 3141, ESC-K which housed the Light Engineer Platoon was taken over by the 5th Maintenance Company and ESC-K for use of a Small Arms Repair Area and Refrigeration repair area respectively. Bldg 3057 which housed the Commel and Commel and Small Arms repair area for the 8903rd CLG Co, and the Commel Area for the 5th Maintenance Company. The Joint Services Security Intrusion Detection System in the Secure Area of Bldg 3057 has been non-operational since 1 March 1976, awaiting a decision by Kaiserslautern Community as to who will be responsible for the monitoring of the system. A decision directing this responsibility is planned to be made by 1 July 1976. Twenty-two (22) personnel from the 43rd Maint Co were assigned for duty with the 8903rd CLG Co to effect a smooth and efficient transfer of mission responsibility. These individuals will remain for periods varying up to 180 days in duration after the 43rd deactivation. (3) 43rd Maintenance Company. - The reporting period is 1 January 1976 to 20 June 1976. The unit received 1267 work orders during the report period and completed 1903 work orders. The average work order completion rate was 380 work orders and a month backlog of 650 work orders was maintained. During May the transfer of work orders to the 8903rd CLG Co which is scheduled to assume the mission of the 43rd Maintenance Company was begun. A total of 526 open job orders was transferred during May to the 8903rd and the 43rd Shop office was closed out effective 28 May 1976 with the transfer of the last 28 work orders to the 8903rd CDG Co. As a result of the inactivation, the unit transferred its mission responsibility in all commodity areas starting the 10th of May with Shop Supply and Light Engineer platoon and concluding with the Commel platoon on 15 June 1976. Mission Shop space formerly utilized by the unit was realigned between the 5th Maintenance Company, ESC-K and 8903rd CLG Co. Bldg 3047, ESC-K which housed the 43rd Shop Office, Shop Supply, Heavy Engineer Equipment Repair Section, Automotive Repair Section, and Service Section was turned over to the 5th Maintenance Company. Bldg 3141, ESC-K which housed the Light Engineer Platoon was taken over by the 5th Maintenance Company and ESC-K for use of a Small Arms Repair Area and Refrigeration repair area respectively. Bldg 3057 which housed the Commel and Commel and Small Arms repair area for the 8903rd CLG Co, and the Commel Area for the 5th Maintenance Company. The Joint Services Security Intrusion Detection System in the Secure Area of Bldg 3057 has been non-operational since 1 March 1976, awaiting a decision by Kaiserslautern Community as to who will be responsible for the monitoring of the system. A decision directing this responsibility is planned to be made by 1 July 1976. Twenty-two (22) personnel from the 43rd Maint Co were assigned for duty with the 8903rd CLG Co to effect a smooth and efficient transfer of mission responsibility. These individuals will remain for periods varying up to 180 days in duration after the 43rd deactivation.

(4) 91st Maintenance Company - The reporting period is 1 January 1976 to 20 June 1976. During this period the company has continued the mission of the direct exchange facility of the component repair mission, and the Collection, Reclamation and Exchange (CRE) activities until 5 May 1976. As the result of unit inactivation, the unit's mission was transferred to the 8901st Civilian Labor Group. As a result of the unit inactivation the organization transferred all stockage of repair parts, stock record accounts and maintenance control system records to the 8901st Labor Service Company between the period of 30 April to 5 March 1976. On 20 March 1976, all mission and organizational equipment began it's identification and classification for turn-in and/or lateral transfer to various units within the 66th Maintenance Battalion and the 1st Support Brigade. (4) 91st Maintenance Company - The reporting period is 1 January 1976 to 20 June 1976. During this period the company has continued the mission of the direct exchange facility of the component repair mission, and the Collection, Reclamation and Exchange (CRE) activities until 5 May 1976. As the result of unit inactivation, the unit's mission was transferred to the 8901st Civilian Labor Group. As a result of the unit inactivation the organization transferred all stockage of repair parts, stock record accounts and maintenance control system records to the 8901st Labor Service Company between the period of 30 April to 5 March 1976. On 20 March 1976, all mission and organizational equipment began it's identification and classification for turn-in and/or lateral transfer to various units within the 66th Maintenance Battalion and the 1st Support Brigade.

(5) 546th Maintenance Company - The unit provides Direct Support Maintenance Service on an area basis for military standard equipment, generally associated with Tank-Autommotive and Mobility Equipment and Electronic Commodity Command. In addition, the 546th Maintenance Company provides limited Recovery-Evacuation Support, a Contact Team in support of the 5th CEC at Miesau Army Depot, and Technical Assistance to supported customers. As a result of the increased work load, the Fual & Electrical Section was activated on 10 April 1976 to support the Automotive Shop. Due to the sensitive nature of Commel Equipment, the section was relocated to Bldg 4403, Husterhoeh Kaserne, on 10 September 1976. During the reporting period, the unit supported 54 customers; it received 9437 job orders and completed 8564 of them. (5) 546th Maintenance Company - The unit provides Direct Support Maintenance Service on an area basis for military standard equipment, generally associated with Tank-Autommotive and Mobility Equipment and Electronic Commodity Command. In addition, the 546th Maintenance Company provides limited Recovery-Evacuation Support, a Contact Team in support of the 5th CEC at Miesau Army Depot, and Technical Assistance to supported customers. As a result of the increased work load, the Fual & Electrical Section was activated on 10 April 1976 to support the Automotive Shop. Due to the sensitive nature of Commel Equipment, the section was relocated to Bldg 4403, Husterhoeh Kaserne, on 10 September 1976. During the reporting period, the unit supported 54 customers; it received 9437 job orders and completed 8564 of them.

(6) 593rd Supply and Service Company - The Field Service mission increased this year with the Laundry and Bath Platoon receiving over 50 mission requirements during the year. Support was provided throughout Western Germany and included support of Brigade 76, Reforger 76 and many smaller field and CPX exercises. During the entire year the Platoon also maintained a bath point at Miesau Army Depot to support a platoon of infantry troops who have been detailed to augment the regular depot guard force. The Reefer Detachment provided extensive support for not only community affairs but for field exercises as well. The Detachment received extensive praise for its efforts during the Nijmegen Marches and the Able Archer CPX. Although these were two of the most noteworthy and extensive support requirements the detachment provided outstanding support in all assigned missions and was able to maintain an operational rate of 80% or better at all times. The Class II, IV, and VII supply activity formerly AK4424 was redesignated WK4GBW and the number of supported customers has risen to well over 200 due to many unit reorganizations and moves during the year. The Class Ill supply activity formerly AK4949 was redesignated W4GBO and the amount of petroleum product distributed increased by approximately 10% over the last CY. The Tank Farm was placed back in operation after being idle for nearly 14 months during August 1976 after completion of work to replace valves and minor pipe line repair. Plans were initiated during the fall of the year for a FRG funded upgrade program to improve the Tank Farm during CY 1977. Improvements will consist of new pumps, new berms around the storage tanks, improvement of the rail point, repair of the package ramp and many other minor but sorely needed repairs to the entire yard. A new mission support requirement was added to the 593rd with the attachment of the Troop Issue Support Activity Pirmasens, effective 1 October 1976. All other mission assignments were retained and support activity continued to increase during the year. (6) 593rd Supply and Service Company - The Field Service mission increased this year with the Laundry and Bath Platoon receiving over 50 mission requirements during the year. Support was provided throughout Western Germany and included support of Brigade 76, Reforger 76 and many smaller field and CPX exercises. During the entire year the Platoon also maintained a bath point at Miesau Army Depot to support a platoon of infantry troops who have been detailed to augment the regular depot guard force. The Reefer Detachment provided extensive support for not only community affairs but for field exercises as well. The Detachment received extensive praise for its efforts during the Nijmegen Marches and the Able Archer CPX. Although these were two of the most noteworthy and extensive support requirements the detachment provided outstanding support in all assigned missions and was able to maintain an operational rate of 80% or better at all times. The Class II, IV, and VII supply activity formerly AK4424 was redesignated WK4GBW and the number of supported customers has risen to well over 200 due to many unit reorganizations and moves during the year. The Class Ill supply activity formerly AK4949 was redesignated W4GBO and the amount of petroleum product distributed increased by approximately 10% over the last CY. The Tank Farm was placed back in operation after being idle for nearly 14 months during August 1976 after completion of work to replace valves and minor pipe line repair. Plans were initiated during the fall of the year for a FRG funded upgrade program to improve the Tank Farm during CY 1977. Improvements will consist of new pumps, new berms around the storage tanks, improvement of the rail point, repair of the package ramp and many other minor but sorely needed repairs to the entire yard. A new mission support requirement was added to the 593rd with the attachment of the Troop Issue Support Activity Pirmasens, effective 1 October 1976. All other mission assignments were retained and support activity continued to increase during the year.

(7) 8901st Civilian Labor Group - During the reorganization/civilianization, the unit was assigned the mission to hire and train personnel for the two new Civilian Labor Group units. Approximately 320 individuals were hired and trained, for this purpose, between January 1976 and June 1976. Starting in March the unit took over the mission previously assigned to the 91st Maintenance Company. Effective 1 May 1976 the unit fully assumed the mission of the 21st Support Command centralized direct exchange facility in support of Support Command Stock Record Accounts. At present, 230 line items of components are available at the 8901st D/X point. To support the direct exchange activity, the maintenance shop was rearranged and the component repair section enlarged. In the average 2400 items are being repaired by this section per month. Under the TARP program the 8901st repaired 954 1¼ ton gasoline engines and 231 multi fuel engines during 1976. In June 1976 the unit fully assumed the mission of the 21st Support Command Equipment Collection and Classification Activity. During 1976 the inspection and major item section received, inspected and processed 3228 pieces of equipment. The major item section of SSA WA4GBZ conducted 5711 paper transactions to obtain disposition instructions for the items received by this section. The Disassembly and Salvage mission of the former 91st Maintenance Company was picked up in May 76. Through the efforts of unit self-help, the cann-point was relocated and organised, and began to be fully operational in July. In 1976, 1267 different pieces of equipment were processed through the cann-point and were made available to customer units to obtain repair parts and components. (7) 8901st Civilian Labor Group - During the reorganization/civilianization, the unit was assigned the mission to hire and train personnel for the two new Civilian Labor Group units. Approximately 320 individuals were hired and trained, for this purpose, between January 1976 and June 1976. Starting in March the unit took over the mission previously assigned to the 91st Maintenance Company. Effective 1 May 1976 the unit fully assumed the mission of the 21st Support Command centralized direct exchange facility in support of Support Command Stock Record Accounts. At present, 230 line items of components are available at the 8901st D/X point. To support the direct exchange activity, the maintenance shop was rearranged and the component repair section enlarged. In the average 2400 items are being repaired by this section per month. Under the TARP program the 8901st repaired 954 1¼ ton gasoline engines and 231 multi fuel engines during 1976. In June 1976 the unit fully assumed the mission of the 21st Support Command Equipment Collection and Classification Activity. During 1976 the inspection and major item section received, inspected and processed 3228 pieces of equipment. The major item section of SSA WA4GBZ conducted 5711 paper transactions to obtain disposition instructions for the items received by this section. The Disassembly and Salvage mission of the former 91st Maintenance Company was picked up in May 76. Through the efforts of unit self-help, the cann-point was relocated and organised, and began to be fully operational in July. In 1976, 1267 different pieces of equipment were processed through the cann-point and were made available to customer units to obtain repair parts and components.

(8) 8903rd Civilian Labor Group - The unit provides General Support and back-up Direct Support for military standard equipment generally associated with the tank-automotive, engineer, electronic and armament commodities and also provides support for the Theater Army Repair Programs (TARP) and for the Combat Material Upgrade Programs (CHU). During the period 1 April 1976 thru 31 December 1976, the unit received 2,887 job orders and completed 2,359 of them. (8) 8903rd Civilian Labor Group - The unit provides General Support and back-up Direct Support for military standard equipment generally associated with the tank-automotive, engineer, electronic and armament commodities and also provides support for the Theater Army Repair Programs (TARP) and for the Combat Material Upgrade Programs (CHU). During the period 1 April 1976 thru 31 December 1976, the unit received 2,887 job orders and completed 2,359 of them.

(9) 8907th Civilian Labor Group - The unit provides General Support maintenance, overflow direct support maintenance, and supply support for tactical wheeled vehicles. The unit is commodity loaded to support ¼ T, 5/4 T, 2½ T, 5 T Trucks and all Trailers under repair program (i.e.: ERC, TARP, CMU and Special Projects). During the reporting time the 8907th CLG has received 309 work orders for major items in the ECC 33 and has completed 144. Favorable work output was accomplished for the CMU and ERC programs. The following tactical wheeled vehicles were overhauled or repaired: 20 ea ¼ T Trucks, 11 ea 5/4 T Trucks, 13 ea 5 T Trucks, 66 ea 5 T Dump Trucks, 8 ea 2/2 T Trucks, 19 ea other and 7 Trailers. (9) 8907th Civilian Labor Group - The unit provides General Support maintenance, overflow direct support maintenance, and supply support for tactical wheeled vehicles. The unit is commodity loaded to support ¼ T, 5/4 T, 2½ T, 5 T Trucks and all Trailers under repair program (i.e.: ERC, TARP, CMU and Special Projects). During the reporting time the 8907th CLG has received 309 work orders for major items in the ECC 33 and has completed 144. Favorable work output was accomplished for the CMU and ERC programs. The following tactical wheeled vehicles were overhauled or repaired: 20 ea ¼ T Trucks, 11 ea 5/4 T Trucks, 13 ea 5 T Trucks, 66 ea 5 T Dump Trucks, 8 ea 2/2 T Trucks, 19 ea other and 7 Trailers.

(10) Equipment Support Center, Kaiserslautern (ESCK) - The average number of work orders completed per month was 976, while a constant backlog of 950 was maintained. Supply Support Activity WK4GB6 became the theater DX point for the LD 465-1 engine as of 8 June 1976. The following FY 77 repair programs were assigned effective 1 October 1976: 220 trailers M127A1 and M127A2; 1044 multifuel 2½ ton engines LD 465-1, 2½ ton; 42 truck vans M109A3; 9600 side boards for semi-trailers; 191 reefer vans M349; and 1097 reefer slip-in units. These programs were adopted without increase in personnel, as the maintenance support for Facilities Engineer Kaiserslautern and the school bus program for TMP Kaiserslautern were eliminated. The major assembly stop was reorganized to line production decreasing the engine repair time from 68 to 55 hours. The engine test room lodging 4 test stands was reconstructed by partition walls into 4 cabins providing better working conditions for mechanics and inspectors by reducing the noise. Based on the Quick Return Investment Program the following equipment was obtained: 2 electrical vehicle lifts; 1 wheel balancing machine; 1 argon welding set; 4 sewing machines; 1 refrigeration unit servicing machine; and 1 torque wrench set. The modernization of shop equipment provides for safe operation and resulted in an excellent service to our customers by reducing the turn-around time. (10) Equipment Support Center, Kaiserslautern (ESCK) - The average number of work orders completed per month was 976, while a constant backlog of 950 was maintained. Supply Support Activity WK4GB6 became the theater DX point for the LD 465-1 engine as of 8 June 1976. The following FY 77 repair programs were assigned effective 1 October 1976: 220 trailers M127A1 and M127A2; 1044 multifuel 2½ ton engines LD 465-1, 2½ ton; 42 truck vans M109A3; 9600 side boards for semi-trailers; 191 reefer vans M349; and 1097 reefer slip-in units. These programs were adopted without increase in personnel, as the maintenance support for Facilities Engineer Kaiserslautern and the school bus program for TMP Kaiserslautern were eliminated. The major assembly stop was reorganized to line production decreasing the engine repair time from 68 to 55 hours. The engine test room lodging 4 test stands was reconstructed by partition walls into 4 cabins providing better working conditions for mechanics and inspectors by reducing the noise. Based on the Quick Return Investment Program the following equipment was obtained: 2 electrical vehicle lifts; 1 wheel balancing machine; 1 argon welding set; 4 sewing machines; 1 refrigeration unit servicing machine; and 1 torque wrench set. The modernization of shop equipment provides for safe operation and resulted in an excellent service to our customers by reducing the turn-around time.

d. Exercises: Units of the Battalion participated in three major exercises - REFORGER 76, Brigade 76 and NATO CPX ABLE ARCHER. d. Exercises: Units of the Battalion participated in three major exercises - REFORGER 76, Brigade 76 and NATO CPX ABLE ARCHER.

(1) REFORGER 76 - All units, with the exception of ESCK, participated in REFORGER 76. Normal supply, maintenance and convoy support was provided to REFORGER 76 units. The Battalion was tasked to operate the Line of Communications (LOC) Headquarters in the Netherlands. Members of the Battalion Staff were used to man the LOC. In addition, the 5th Maintenance Company provided a maintenance team to support REFORGER 76 vehicles of the 101st Airborne Division (air mobile) to Belgium while the 546th Maintenance Company provided similar support in the Netherlands. These maintenance teams also provided Class II IV and IX supply support. Overall performance was judged to be a success by the many favorable comments received and by the formal recognition rendered. (1) REFORGER 76 - All units, with the exception of ESCK, participated in REFORGER 76. Normal supply, maintenance and convoy support was provided to REFORGER 76 units. The Battalion was tasked to operate the Line of Communications (LOC) Headquarters in the Netherlands. Members of the Battalion Staff were used to man the LOC. In addition, the 5th Maintenance Company provided a maintenance team to support REFORGER 76 vehicles of the 101st Airborne Division (air mobile) to Belgium while the 546th Maintenance Company provided similar support in the Netherlands. These maintenance teams also provided Class II IV and IX supply support. Overall performance was judged to be a success by the many favorable comments received and by the formal recognition rendered.

(2) Brigade 76 - The 5th Maintenance Company provided maintenance support for the 1st Infantry Division and the 2nd Armored Division enroute from COMZ to predetermined training sites. Maintenance and convoy support was provided for over 400 vehicles; all established convoy time tables were met. The 593rd Supply and Service Company provided extensive laundry and bath support. Again, the mission was judged a success by the many favorable comments received. (2) Brigade 76 - The 5th Maintenance Company provided maintenance support for the 1st Infantry Division and the 2nd Armored Division enroute from COMZ to predetermined training sites. Maintenance and convoy support was provided for over 400 vehicles; all established convoy time tables were met. The 593rd Supply and Service Company provided extensive laundry and bath support. Again, the mission was judged a success by the many favorable comments received.

(3) ABLE ARCHER - The 546th Maintenance Company provided support to elements of the 91st Infantry Division, the 81st Airborne Brigade and the 1st US Cavalry Division. An eight man contact team provided technical assistance for Organizational and Direct Support maintenance around the clock. In addition, the 546th Maintenance Company provided convoy/recovery support during the deployment and redeployment phases. Commanders, at all levels, commended the contact team for excellent support rendered and for its technical expertise. (3) ABLE ARCHER - The 546th Maintenance Company provided support to elements of the 91st Infantry Division, the 81st Airborne Brigade and the 1st US Cavalry Division. An eight man contact team provided technical assistance for Organizational and Direct Support maintenance around the clock. In addition, the 546th Maintenance Company provided convoy/recovery support during the deployment and redeployment phases. Commanders, at all levels, commended the contact team for excellent support rendered and for its technical expertise.

e. The emphasis on individual and group training remains consistent. Particular emphasis is placed on civilian schooling and english as a second language. In March 1976 the Battalion began german language training. Training is only required for E7s and above; as many service members as possible will be trained, however. In November, the Battalion began english language training for members of the Civilian Labor Groups who need the training. The chaplain has been conducting Personal Effectiveness Training for personnel at supervisory levels. The training concentrates on communications with others in an attempt to foster understanding and concerned leadership in our supervisors. e. The emphasis on individual and group training remains consistent. Particular emphasis is placed on civilian schooling and english as a second language. In March 1976 the Battalion began german language training. Training is only required for E7s and above; as many service members as possible will be trained, however. In November, the Battalion began english language training for members of the Civilian Labor Groups who need the training. The chaplain has been conducting Personal Effectiveness Training for personnel at supervisory levels. The training concentrates on communications with others in an attempt to foster understanding and concerned leadership in our supervisors.

f. Significant Events: The Battalion units celebrated a consolidated Organizational Day on 30 July 1976. ESCK celebrated its 25th Anniversary in May 1976. HHD and the Civilian Labor Groups jointly sponsored the 262nd HEM Company, a Delaware National Guard unit. The support rendered enabled the 262nd HEM Company to have its best, most productive summmer camp ever. On 9 July 1976, a formal activation ceremony was conducted for the three Civilian Labor Group units. BG Robert C. Gaskill, CG of 1st Support Brigade, and LTC Jerry N. Lindsey, Battalion Commander, participated in the ceremony. Each of the unit's colors were formally presented to the unit commanders. The units were officially welcomed into the 66th Maintenance Battalion. f. Significant Events: The Battalion units celebrated a consolidated Organizational Day on 30 July 1976. ESCK celebrated its 25th Anniversary in May 1976. HHD and the Civilian Labor Groups jointly sponsored the 262nd HEM Company, a Delaware National Guard unit. The support rendered enabled the 262nd HEM Company to have its best, most productive summmer camp ever. On 9 July 1976, a formal activation ceremony was conducted for the three Civilian Labor Group units. BG Robert C. Gaskill, CG of 1st Support Brigade, and LTC Jerry N. Lindsey, Battalion Commander, participated in the ceremony. Each of the unit's colors were formally presented to the unit commanders. The units were officially welcomed into the 66th Maintenance Battalion.

g. Host Country Relations: Overall relations between US military and local nationals remain good with a low incident rate. Each US unit has a German partnership unit with which various activities are performed jointly. g. Host Country Relations: Overall relations between US military and local nationals remain good with a low incident rate. Each US unit has a German partnership unit with which various activities are performed jointly.

h. Welfare, Recreation and Morale: Morale throughout the Battalion remains high. Two units have moved into billets recently renovated under the MOUSF project. Recreation is good with units actively supporting community sports programs. The intra-Battalion sports program continues with active support from the units. h. Welfare, Recreation and Morale: Morale throughout the Battalion remains high. Two units have moved into billets recently renovated under the MOUSF project. Recreation is good with units actively supporting community sports programs. The intra-Battalion sports program continues with active support from the units.

FOR THE COMMANDER

|

| |

(Signature)

VICTOR B. BAKO, JR.

CPT, AGC

Adjutant |

|

|

|

|

| 5th Maintenance Company |

| |

| 1987 |

(Source: Support Sentinel, March 11, 1987) |

5th Maint delivers 'class' act

By SSgt Willie Hay

They're in the repair, replace and recovery business.

The more than 260 soldiers of the 5th Maint Co, 66th Maint Bn, Kaiserslautern, provide direct support maintenance to 85 customer units for all military standard automotive, armament, generator, communications/electronics and materiel handling equipment. The 5th also runs a Class IX Supply Support Activity for this equipment with an authorized stockage list for more than 4,000 different repair parts on hand to support 103 customer units.

"Our soldiers are assigned to five platoons -- Headquarters, Technical Supply, Mechanical Maintenance, Direct Support, and Service Platoon." said Capt Dean A. Powell, company commander. "Our Direct Support Platoon has the dual mission of repairing all kinds of armaments, from M16 rifles to the major gun systems, as well as performing maintenance on all wheeled and tracked vehicles.

"Service Platoon is made up of a service and evacuation section that provides recovery support 24 hours a day to disabled vehicles on the autobahn north of Autobahn A-6, from the Rhine River to the French border," he continued. "The soldiers recover vehicles on a one-hour notice and move them to our maintenance facility on the Equipment Support Center Kaiserslautern for any necessary repairs, including glass, welding, bodywork and canvas repair."

According to Powell, the hub of the Class IX activity is the unit's DAS3 (Direct Support Supply System) computer. "With DAS3, we can supply class IX repair parts for any automotive. armament, generator, communications or materiel handling equipment," he said. "And if we don't have it on hand, we can get it.

"My soldiers work around the clock to maintain what we call 'no jobs over 60' status," Powell said. "That means none of the jobs on hand are held for more than 60 days -- a goal they've achieved in addition to maintaining their own individual equipment, responding to emergencies on the autobahn and taking part in field training exercises."

|

|

|

|

| 531st Ordnance Company (DS) |

| |

| 1951 |

| (Source: STARS & STRIPES, December 27, 1951) |

The 531st Ordnance Medium Maintenance Company, stationed at Sullivan Barracks in Kaefertal, is commanded by Capt Charles R. Fish, of Janesville, Wis.

The unit's mission is to provide complete ordnance support, except for ammunition, for seven battalions and 51 companies of the 7th Army. The company replaces engines and services some 1,000 wheeled vehicles and 450 tracked vehicles. It also services instruments,

artillery pieces and small arms for those units.

In addition to its main mission, there is the "transient" business that the company has recently performed for newly arrived units of the 2d Armored and 4th Infantry Divisions. Once an M26 medium tank, for instance, comes into the 531st tank shop, at any hour of the day or night, a crew goes to work immediately for from three to five hours and doesn't stop until the tank is ready to roll again.

More than 11,000 line items of issue are stocked in the ordnance supply section, headed by Sfc Agneu Stanley. "Versatile support" is what

he calls his 50 tons of depot stock.

The Instrument Repair Section of the 531st calls for highly specialized men. There binoculars, battery commanders' scopes, azimuth indicators, ordnance compasses, pocket and wrist watches, periscopes and other fine instruments are refocused, repaired and reconditioned.

In the Small-Arms Section, the sights of rifles and carbines are reset and adjusted, trigger housings and bolts are stripped down and worn and defective parts replaced in rocket launchers and automatic rifles.

Men assigned to the Tracked-Vehicle Section overhaul amphibious vehicles and half-tracks.

Crews in the Artillery Section go over 90-mm guns and gun carriages. |

|

| |

| 1955 |

(Source: Email from Tom Williams, 531st Ord Co, 1955-1957) |

I was shipped overseas April, 1955 on the USNS Patch. 2 weeks later I was assigned to the above Co. which was at Sullivan Barracks, Mannheim, Germany. The 531st had been in Europe since the 2nd World War! With a lot of history. When I arrived we were part of 66th Ord Bn, 7th Army,

I spent 29 months overseas and returned to the U.S. aboard the USNS Buckner October, 1957. I'm e-mailing you some pictures of the kaserne and men of the 531st!

|

531st Ord Co - 1955-57

Mannheim |

|

|

|

|

1. Main gate, Sullivan Bks (KB)

|

2. Tom Williams and Sgt Steele (KB)

|

3. Tom Williams (KB)

|

|

4.

Don Massman & Ken Schur (KB) |

5. Ken Schur & Tom Williams (KB) |

|

|

6. Christmas Card, 1955 (KB) |

Company Roster, Dec 1955

Page 1 Page 1

Page 2 Page 2

Page 3 Page 3

|

|

|

7. U.S.N.S. Patch (KB) |

8. U.S.N.S. Buckner (KB) |

|

|

|

|

|

|

| 547th Ordnance Company (Field Maintenance) |

| |

| Equipment Maintenance Group, US Army Area Command |

| |

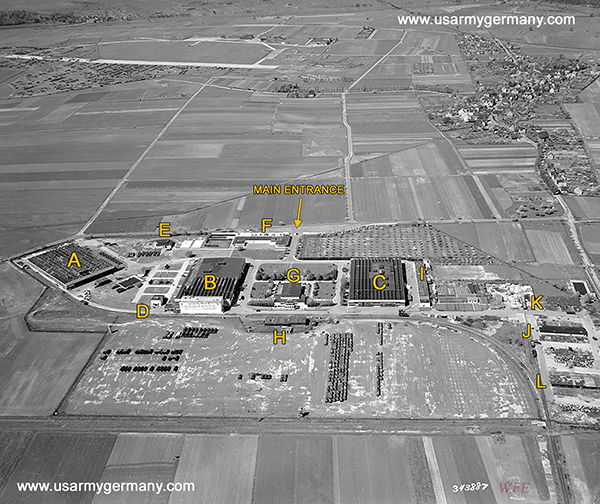

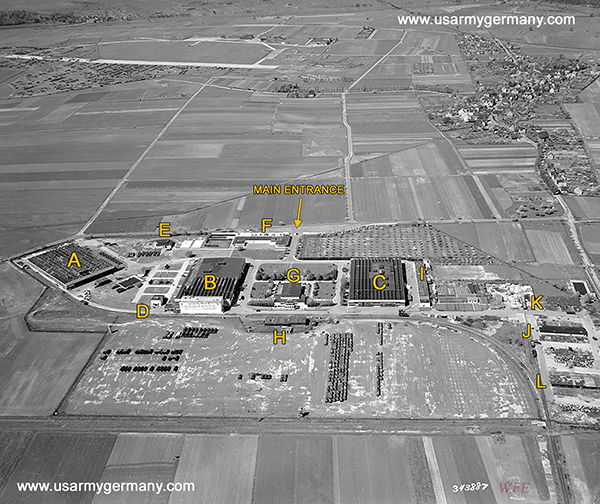

"C" is the 547th Ord Co Shop area, Waldau Kaserne, Kassel (Webmaster's collection) |

| |

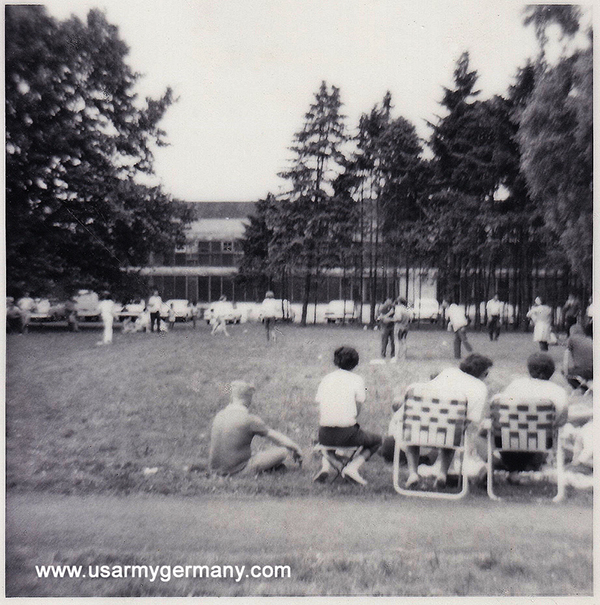

The 547th at a picnic at Waldau Kaserne. The front of the building is to the left. |

| |

| 1965 |

| (Source: Email from Roger Petersen) |

The 547th Ordnance Company was based in Rothwesten and had the maintenance facility in Waldau (Kassel).

In January 1965 I was assigned to the 547th Ordnance Co. The company was stationed at Rothwesten Kaserne and had maintenance buildings in both Rothwesten and Waldau.

The Rothwesten maintenace unit handled civilian type motor vehicles and Waldau handled military motor vehicles. Ammunition was also stored in Waldau.

The barracks in Rothesten were two stories high and a basement (Supply Room). There were tunnels connecting all the buildings that were sealed off due to concerns about unexploded devices within. Rothwesten was an underground airfield during the war. That was also sealed up.

There was a signal unit and a transportation battalion also stationed in Rothwesten. There was also an ASA unit and Hawk missle unit stationed there.

The 547th Ordnance Field Maintenance Company was assigned to the Equipment Maintenance Group (EMG) in April 1965 and was the only military unit that served with all the other civilian run maintenance centers in the EMG.

In 1966 547th started sending small units of personnel to France to help move units and equipment back to Germany (Operation FRELOC). DeGaulle gave the US to the end of 1967 to remove all units and their equipment from France. Eventually one half of the company was in France on temporary duty.

When I first was assigned to 547th I worked in the shop office in Waldau. In August 1966 after the first few people were sent to France I was told (not volunteered) that I was now the Unit Supply Sergeant. They sent me to a 1-week course at the Murnau School to learn supply and I got a promotion to Staff Sergeant at the same time. Turned out to be a good move for me.

I left the 547th in early January 1968 to return back to the states.

ADDITIONAL INFORMATION

Many civilian workers for the Army in France moved to Germany to keep their well-paid jobs. Our Rothwesten maintenance office had a slot for a secretary and they got a French female to fill it. Another funny story.

Tons of machinery was dropped in some of the 547th buildings in Waldau with many unrecognizable as to what they were. Millions of dollars laying around.

Interesting note: over my 20 years in the Army I saw many people I knew in the 547th at different places the world, keeping in mind our unit strength was about 100.

Bldg "C" (photo above) was the 547th. There is a narrow long building along side of it that was used as a machine shop, weapons repair and others like canvas repair etc.

The shop office was upstairs along with a place to eat and a few other offices for what I don't remember.

The basement of the building was billeting and mess hall for traveling units, mainly the 106th Transportation Battalion (I believe the # is correct). These were the main units supported. The battalion served the northern half of Germany.

At the back end of the building in the basement was the furnace room including water heating. The fireman always had a problem wth "shiza collen." (Webmaster note: German speakers will be able to figure that out!)

The 547th also did some rebuild work but I don't know what the extent was. Trucks for sure.

During my time there the Army changed out the M52 tractors (I think the correct nomenclature) for commercial cab-over tractors. Maintenance went way up as these units were accident prone and the contract the Army had with the manufacturer didn't allow for disposing of a tractor during the first year.

We had a tractor fully knocked down to the frame (frame sent out for straitening) and rebuilt with all new parts. Back then cost over $100G when we were buying them for $2000 (approx).

As a result of the new tractors the civilian workers numbers were increased when McNamara was trying reduce population.

The picture does not have the round concrete building that was used for storage of ammunition that I can see.

I remember a German Army pilot used to fly his helicopter in and buzz the building. The Shop NCO lived on the economy with his German wife and the pilot was a friend. |

|

| |

| 66th Maintenance Battalion |

| |

| |

| |

| |

| |

|

| |

| 51st Maintenance Battalion |

| |

| 1971 |

| (Source: STARS & STRIPES, Feb 26, 1971) |

| The 547th Maintenance Company, 66th Maint Bn, in Kaiserslautern, was recently transferred to the 51st Maint Bn. The change also included a station move to Germersheim Army Depot. |

|

|

|

| 8901st Civilian Support Group |

| |

| |

| |

|

|

|

| 8903rd Civilian Support Group |

| |

(Source: Email from Roman Buchner, 8903rd CSG) |

Three members of the 8903rd during a coffee break - Roman Buchner is on the left.

|

|

I was always very proud to have served with the US Army. For a long time I served at Miesau Army Depot. The 8903rd had a detachment of the Automotive Section stationed there and we provided support to one of the companies there, I believe it was the 6th (CEC?). Putting the detachment there allowed us to perfom work orders on the spot and minimize the effort and time normally involved with transporting heavy equipment needing repair to our shops in Kaiserslautern.

|

|

|

| |

(Source: Support Sentinel, Oct 8, 1986) |

CSGs whip Americans in maintenance sweepstakes

By SSgt Willie Hay

A civilian support group assigned to the 66th Maint Bn received the 21st SUPCOM's first Maintenance Management Review Award in competition with their US Army counterparts.

The 8903rd CSG received a certificate of achievement and plaque Sept. 30 for the operation of its decentralized automated service support system, or DAS3, from Brig Gen William G. Pagonis, 21st SUPCOM deputy commanding general. On-the-Spot Awards were presented to local national system operators Harald Leidecker and Rieta Koelsch and Army Achievement Medals to system maintainers SSgt Virginia Oxx and Sp4 Carl Daniels.

According to Lt Col James R. Steverson, assistant chief of staff, Information Management, the awards recognized the 8903rd's performance during a review of system maintenance and logging procedures at the command's 18 DAS3 sites between March and May 1986.

"The 8903rd was the best in maintenance, system reporting and subsystem operation," said Sgt Guido Munno, HQ 21st SUPCOM DAS3 repairer, who suggested that the command present annual Maintenance Management Review Awards.

"DAS3 keeps track of the repair parts that a unit stocks and issues to the units it supports," Steverson said. "For instance, if one of the units needs a repair part for a tank, they go to the 8903rd to obtain it."

The DAS3 is a tactical, van-mounted computer that, in time of war, accompanies the unit to the battlefield, according to Steverson. Other 21st SUPCOM units that have the system are CEGE, the 70th Trans Bn and the 51st Maint Bn.

"Stock records weren't always accurate when they were done by hand," Munno said. "But with the DAS3, when you put in a requisition for, say, 10 parts for a tank turret, the daily cycle will minus it from whatever you have on hand. If a part is unavailable, the computer automatically requisitions it for you."

Steverson said that the 8903rd is one of many civilian support groups trained in such operations as supply, maintenance and transportation for US Army units. The 8903rd's mission includes both direct support and general support maintenance for the 66th Maint Bn.

Oxx and Daniels both hold MOS 34C, DAS3 repairer. Their job entails daily preventive maintenance, periodic system checks and cleaning, and repairing equipment after a malfunction.

"During daily operations, the DAS3 repairer reviews the system's performance with the operator," Steverson said. "If anything odd has happened, the repairer performs a quality check, reviewing the print-outs and the operator's log to find out if any problem has gone unnoticed."

Accroding to Oxx, the 8903rd maintains a prescribed load list of more than 300 line items that make up the unit's supply system. "If our computer goes down, we don't go home until we get it fixed," Daniels said.

"Stock control activities such as the 8903rd are required to process 27-30 daily cycles per month -- essentially one per work day -- to take care of their customers' needs quickly," Steverson explained. "The 8903rd crew has done such a superior job that their computer has always been available. Awards such as these recognize those people who generally work behind the scenes at odd hours to make sure the supplies keep coming."

|

|

|

|

| 8907th Civilian Support Group |

| |

| |

| |

|

|

| |

|

Related Links:

|

| |

| |

|

66th Ordnance Bn DI (not

sure if this was worn in Germany)

66th Ordnance Bn DI (not

sure if this was worn in Germany) 66th Maint Bn DUI

66th Maint Bn DUI