If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany'

frameset |

US

Army Industrial Center, Europe

Communications Zone

Looking for more information from military/civilian

personnel assigned to or associated with the U.S. Army

in Germany from 1945 to 1989. If you have any

stories or thoughts on the subject, please contact me . .

|

|

|

|

|

| |

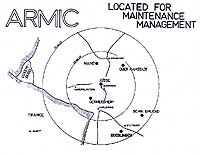

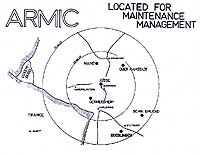

| ARMIC

History |

|

| 1958

- 19.. |

| (Source: Command

Briefing, Hqs ARMIC. The US Army Industrial Center, Europe, Coleman

Barracks, Mannheim-Sandhofen, APO 28.) |

|

|

|

YEAR

|

|

|

1947

|

7841st

Ordnance Procurement Center establishes European Liaison

Offices. |

|

1951

|

7841st

Ordnance Supply Group organized; commands Mannheim, Pirmasens,

Nancy, Braconne, Fontenet, Germersheim, and Rhine Ordnance Depots. |

|

1953

|

53rd

Ord Gp assumes storage, supply & maintenance mission

of ordnance materiel from 7847th Ord Gp. |

|

1954

|

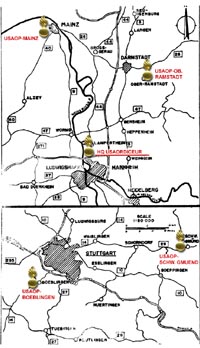

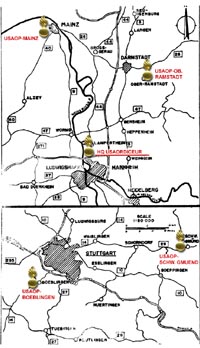

53rd

Ord Gp assumes command of Mainz, Ober-Ramstadt, Böblingen,

Schw. Gmünd & Karlsfeld Ord Depots. |

|

1958

|

53rd

Ord Gp merged with 7841st Ord Procurement, redesignated ORDIC

with command of Ord Plants Mainz, Ober-Ramstadt, Böblingen,

Schw. Gmünd and Procurement Liaison Officesin Rome, Paris,

London, Madrid and BENELUX. |

|

1963

|

Procurement

activities consolidated with Procurement Center Frankfurt; USAOD-Germersheim

assigned to ORDIC. |

|

1964

|

ARMIC

commands USAMP's Böblingen, Mainz, O.-Ramstadt & Schw.

Gmünd and USAD Germersheim. |

|

| |

|

|

.

|

|

| |

| ARMIC

INDUSTRIAL FACILITIES |

USAMP

BÖBLINGEN

- MISSION

- Depot

Maintenance Light Combat Vehicles

- FY-64

PROGRAM MAJOR ITEMS

- 181

APC's

- 28,215

Canvas Items

- 105

Tank Retrievers (VTR)

- 143

Missile Support Items

- 871

Power Train Assy's

- 821

Tac Vehicles

- FACILITIES

- SPECIAL

CAPABILITIES

- Vehicle

steam clean, de-rust, sand-blast & paint facilities

- Complete

sheet metal facilities & carpenter shop

- Canvas

fabrication & repair

- 6-light

engine dynamometers

- Vehicle

test track with 30/60 percent slop

|

|

|

USAMP

MAINZ

- MISSION

- Depot

Maintenance Combat Vehicles

- FY-64

PROGRAM MAJOR ITEMS

- 303

Tanks

- 203

Artillery

- 1355

Fire Control Items

- 2279

Power Train Assy's

- 28

VTR's

- FACILITIES

- SPECIAL

CAPABILITIES

- Metal

plating & metal spraying

- Heavy

vehicle test track with 30/60 percent slope

- 6-heavy

engine dynamometer test cells

- Complete

machine shop incl. crankshaft grinders

- Gun

tube magnaflux

|

|

|

USAMP

OBER-RAMSTADT

- MISSION

- Tire

Recap & Manufacture of Rubber Items

- FY-64

PROGRAM MAJOR ITEMS

- 103,823

Pneu Tires

- 28,200

Solid Tires

- 65,700

Misc. Rubber Products

- FACILITIES

- SPECIAL

CAPABILITIES

- Mixing

of special rubber compounds

- Manufacture

of specialized extruded & molded rubber dies

|

|

|

USAMP

SCHW.-GMÜND

- MISSION

- Depot

Maintenance Major Assemblies

- FY-64

PROGRAM MAJOR ITEMS

- 10,300

Vehicle Engines

- 10,240

Power Train Components

- FACILITIES

- SPECIAL

CAPABILITIES

- Tool

& die fabrication, forging, metal plating & metal

spraying

- Induction

heat treating

- Component

magnafluxing

- 33-light

engine dynamometers

- Complete

machine shop incl. milling & boring machines

|

|

|

- MISSION

- Receives,

Stores, Issues Supplies & Materiel

- FY-64

PROGRAM MAJOR ITEMS

- Received

-- 58,000 Tons

- Stored

-- 44,000 Tons

- Issued

-- 58,000 Tons

- FACILITIES

- SPECIAL

CAPABILITIES

- Vehicle

processing for overseas shipment

- Vehicle

storage capacity of 6,000 tracked or 12,000 wheeled vehicles

- OVM

processin

|

|

|

US

Army Depot, Germersheim, 1962. |

|

|

|

|

|

(Source:

Email from Melvin

Bielawski, ORDIC, 1959-1965)

|

I

am a WW II veteran, albeit non-combat. I was born and raised in

Toledo, Ohio. I volunteered for immediate induction into the Army

when I was drafted for my first physical. I spent two years in Germany

from November, 1945, to October, 1947. My first assignment in Germany

was with the 633rd Medical Clearing Company, although I was trained

as an infantry GI. I was placed in charge of the hospital in "P.O.W.

Camp 78, Zuffenhausen, Germany". My

book on that experience, so titled, was published in 2002. (It

can be previewed at www.1stbooks.com.)

After obaining my degree from the University of Toledo, thanks to

the G.I. BIll, and during my employment at Rossford Ordnance Depot,

located just outside of Toledo, I accepted a DAC (Department of

the Army Civilian) job July, 1957, in Bremerhaven, Germany, in Management

Services, Office of Comptroller.

In August, 1959, I accepted a position with ORDIC

in Management Services and remained with ORDIC, eventually as Chief

of Management, until I transferred to the Directorate of Management,

Comptroller of the Army, in April, 1965. I retired from Pentagon

in 1982. Began new careers as consultant, writing books, etc., plus

travel with my Bavarian wife, golf, fish, etc.,etc.

As the web site summarizes, ORDIC was the Headquarters responsible

for the command and control of ALL operations of the four principal

Ordnance Corps army depots in Germany, namely Ober-Ramstadt, Boeblingen,

Mainz, and Schabisch-Gmuend. ORDIC reported to COMZ, located in

Orleans, France. All funding, reporting, etc., followed these lines

of authority.

Mainz, primarily responsible for the Army's tanks overhaul, and

Boeblingen, responsible for light combat vehicles, etc., were GOCO

plants, i.e., Govenment Owned-Contractor Operated.

Mercedes Benz had Boeblingen and Mainz had Luther Works-Jordan (this

contract later change hands). Sch. Gmuend and Ober-Ramstadt were

GOGO plants. Both were Government Owned-Government

Operated.

The ORDIC Headquarters was located in Coleman Barracks, just outside

of Mannheim, Germany. All of the assigned military and DACs lived

in Benjamin Franklin Village, near Kaefertal. The ORDIC Headquarters

was abolished in the summer of 1965. A COMZ team comprised of Army,

DACs, and French LN's (local nationals) recommended this action

in their final management and manpower analysis of ORDIC. The COMZ

team included the recommendation that the FIVE installations report

directly to COMZ. The installations were allocated slight increases

in their staffs to accomodate the new missions.

Germersheim (GOGO) Depot was assigned to ORDIC about 1963. But it

too was assigned to COMZ in 1965. In 1959, Col. Woods was the CO,

followed by Col. Dennis, followed by Col. Katz, followed by Col

Shepard. The organization was typical of an Army Ordnance depot,

i.e., Administration, Depot Maintenance and Supply, Engineering,

Inspection, Procurement, and Comproller Divisions. A Finance and

Accounting (TO&E) unit was assigned to ORDIC. The Heidelberg Post

CPO (Civilian Personnel Office) provided the services for DACS.

A CPO in Mannheim provided ORDIC support services for Local Nationals

(LNs).

I still maintain contact with several military and civilians, American

and Germans, who were assigned to ORDIC during my time with the

organization. Mel Bielawski

|

|

|

If you have more

information on the history or organization of ARMIC, please contact me . . |

|

|

| |

| Information

Boolet |

|

| (Source: US

Army Ordnance Industrial Center, Europe - Information Booklet,

1962; copy submitted by Henry A. Ulrich, Jr.) |

HISTORY

OF THE UNITED STATES ARMY ORDNANCE INDUSTRIAL CENTER, EUROPE

Activated 15 August 1958 at Coleman Barracks, Mannheim, Sandhofen,

Germany and assigned to Headquarters, United States Army Communications

Zone, Europe.

MISSION (UNITED STATES ARMY ORDNANCE INDUSTRIAL

CENTER, EUROPE)

1. Procurement: In accordance with directives received from the Department

of Do faces, Department of the Army, Commending General, USAREUR,

Commanding General, US Army Communications Zone, Europe, elements

of the US Navy and the US Air Force. a. Obtain proposals, negotiate,

execute and administer contracts for procurement of Ordnance Corps

supplies, equipment and services, in Europe, the Middle East and North

Africa. h. Negotiate, execute and administer contracts under the Facilities

Assistance Program. c. Negotiate, execute and administer technical

arrangements, license agreements and memorandums of agreement pertaining

to the missile systems developed and produced in Europe. d. Accomplish

procurement studies as requested.

2. Production (Overhaul): a. Combat and special purpose track laying

vehicles. b. Tactical and commercial type wheeled vehicles, trailers

and semi-trailers. c. Small arms. d. Artillery and fire control equipment..

e. Assemblies, sub-assemblies and components thereof. f. Pneumatic

and solid tires, track shoe pads and miscellaneous rubber items. g.

Tools and equipment.

3. Other Functions: a, Manufacturing items required to support the

overhaul mission is ORDIC plants and supply depot requirements or

urgent stock fund requirements.

|

1. Procurement:

In accordance with directives received from the Department of

Defense, Department of the Army, Commanding General, USAREUR,

Commanding General, US Army Communications Zone, Europe, elements

of the US Navy and the US Air Force.

a. Obtain

proposals, negotiate, execute and administer contracts for procurement

of Ordnance Corps supplies, equipment and services, in Europe,

the Middle East and North Africa. a. Obtain

proposals, negotiate, execute and administer contracts for procurement

of Ordnance Corps supplies, equipment and services, in Europe,

the Middle East and North Africa.

b. Negotiate,

execute and administer contracts under the Facilities Assistance

Program. b. Negotiate,

execute and administer contracts under the Facilities Assistance

Program.

c. Negotiate,

execute and administer technical arrangements, license agreements

and memorandums of agreement pertaining to the missile systems

developed and produced in Europe. c. Negotiate,

execute and administer technical arrangements, license agreements

and memorandums of agreement pertaining to the missile systems

developed and produced in Europe.

d. Accomplish

procurement studies as requested. d. Accomplish

procurement studies as requested. |

|

| |

2. Production

(Overhaul):

a. Combat

and special purpose track laying vehicles. a. Combat

and special purpose track laying vehicles.

b. Tactical

and commercial type wheeled vehicles, trailers and semi-trailers. b. Tactical

and commercial type wheeled vehicles, trailers and semi-trailers.

c. Small arms. c. Small arms.

d. Artillery

and fire control equipment. d. Artillery

and fire control equipment.

e. Assemblies,

sub-assemblies and components thereof. e. Assemblies,

sub-assemblies and components thereof.

f. Pneumatic

and solid tires, track shoe pads and miscellaneous rubber items. f. Pneumatic

and solid tires, track shoe pads and miscellaneous rubber items.

g. Tools and

equipment. g. Tools and

equipment. |

|

| |

3. Other

Functions:

a. Manufacturing

items required to support the overhaul mission in ORDIC plants

and supply depot requirements or urgent stock fund requirements. a. Manufacturing

items required to support the overhaul mission in ORDIC plants

and supply depot requirements or urgent stock fund requirements.

b. Salvage

of uneconomically repairable major items, including demilitarization

and reclamation of economically reclaimable secondary items

required in support of overhaul operations. b. Salvage

of uneconomically repairable major items, including demilitarization

and reclamation of economically reclaimable secondary items

required in support of overhaul operations.

c. Modification

of major and secondary items. c. Modification

of major and secondary items.

d. Testing

Laboratory: Operate the Ordnance Testing Laboratory, encompassing

performance of all tests necessary for the establishment of

physical, chemical, and electrical properties and performance

characteristics of engineering samples, pilot and production

samples of materiel procured by the Ordnance Industrial Center.

Provide laboratory services for the US Air Force European Procurement

Program. Operate the command check analysis laboratory for both

Communications Zone and Seventh Army Ordnance Depots of fuel

and oxidizer for the Corporal Guided Missile Program presently

in the European Command. Perform other laboratory services for

USACOMZEUR installations and depots, US Army troops, other technical

service installations and area commands. d. Testing

Laboratory: Operate the Ordnance Testing Laboratory, encompassing

performance of all tests necessary for the establishment of

physical, chemical, and electrical properties and performance

characteristics of engineering samples, pilot and production

samples of materiel procured by the Ordnance Industrial Center.

Provide laboratory services for the US Air Force European Procurement

Program. Operate the command check analysis laboratory for both

Communications Zone and Seventh Army Ordnance Depots of fuel

and oxidizer for the Corporal Guided Missile Program presently

in the European Command. Perform other laboratory services for

USACOMZEUR installations and depots, US Army troops, other technical

service installations and area commands.

e. Engineering

as necessary to accomplish the procurement and overhaul missions. e. Engineering

as necessary to accomplish the procurement and overhaul missions.

f. Ordnance

Drawings and Specifications: Operate the USACOMZEUR repository

and maintain the master file for Ordnance specifications, manufacturing

and inspection drawings, including the furnishing of services

to other theater units as required. f. Ordnance

Drawings and Specifications: Operate the USACOMZEUR repository

and maintain the master file for Ordnance specifications, manufacturing

and inspection drawings, including the furnishing of services

to other theater units as required.

g. Supply

Operations: Incident to mission. g. Supply

Operations: Incident to mission.

h. Technical

Assistance: Field agencies and MAP recipients. h. Technical

Assistance: Field agencies and MAP recipients.

i. Finance

Services: as directed. i. Finance

Services: as directed. |

|

| |

4. Exercises

military command, technical direction and administrative and

operational control over the following USA Ordnance Industrial

Center Plants, Liaison Offices and such others as may be established

by Headquarters, USACOMZEUR.

a. USA Ordnance

Plant, Boeblingen. a. USA Ordnance

Plant, Boeblingen.

b. USA Ordnance

Plant, Mainz. b. USA Ordnance

Plant, Mainz.

c. USA Ordnance

Plant, Ober-Ramstadt. c. USA Ordnance

Plant, Ober-Ramstadt.

d. USA Ordnance

Plant, Schwaebisch-Gmuend. d. USA Ordnance

Plant, Schwaebisch-Gmuend.

e. USA Industrial

Liaison Office, London. e. USA Industrial

Liaison Office, London.

f. USA Industrial

Liaison Office, Paris. f. USA Industrial

Liaison Office, Paris. |

|

| |

|

|

PLANT

LOCATIONS AND MISSIONS

Location: US Army Ordnance Plant, Mainz is located

within the city limits of Mainz, Germany,

Mission: Performs overhaul of combat vehicles,

artillery, fire control, small arms and related secondary items

for Direct Army support, the Army Stock Fund and in support

of the Military Asistance Program.

Location: US Army Ordnance Plant, Ober-Ramstadt,

is located at Ober-Ramstadt, Germany.

Mission: Rebuilds pneumatic and solid tires, track

shoe pads and road wheels for Direct Army support and the Army

Stock Fund. Fabricates a myriad of rubber products for use at

the other plants.

Location: US Army Ordnance Plant, Schwaebisch-Gmuend,

is located at Schwaebisch-Gmuend, Germany

Mission: Performs overhaul of water cooled internal

combustion engines, axles, transmissions, transfer cases and

related components for the Army Stock Fund.

Location: US Army Ordnance Plant, Boeblingen is

located at Boeblingen, Germany.

Mission: Performs overhaul of wheeled tactical

type vehicles, trailers, semi-trailers and certain related secondary

items for Direct Army Support and the Military Assistance Program.

Fabricates canvas items for the Army Stock Fund. |

|

| |

ORDICEUR org chart |

|

LIAISON

OFFICES LOCATIONS AND MISSIONS

Locations: US Army Ordnance Industrial Liaison

Offices are located within the city limits of Paris, France;

and London, England.

Missions: Liaison Offices are assigned the following

missions in the areas of procurement and inspection:

a. Obtain

proposals; negotiate, and administer contracts for Ordnance

material, equipment and services. Includes procurement under

the Military Assistance Program and United States Forces Support

Program. a. Obtain

proposals; negotiate, and administer contracts for Ordnance

material, equipment and services. Includes procurement under

the Military Assistance Program and United States Forces Support

Program.

b. administration

of contracts and technical arrangements under the Facilities

Assistance Program which includes monitoring the development

of Preliminary Surveys and detailed Engineering Project Studies. b. administration

of contracts and technical arrangements under the Facilities

Assistance Program which includes monitoring the development

of Preliminary Surveys and detailed Engineering Project Studies.

c. Provides

advice and assistance in preparation of plans, interpretation

of drawings and specifications. c. Provides

advice and assistance in preparation of plans, interpretation

of drawings and specifications.

d. Accomplishes

and performs in process and final inspections of contract end

items on current contracts as well as related proving ground

tests as required. d. Accomplishes

and performs in process and final inspections of contract end

items on current contracts as well as related proving ground

tests as required. |

|

|

|

|

The

Headquarters, United States Army Ordnance Industrial Center,

Europe, occupies Buildings 50-M and 51-M at Wilson D. Coleman

Barracks, Sandhofen, Germany,

COL Lennard C. Sorensen, Commanding |

|

|

|

|

| |

Related Links:

|

| |

| |

| |

| |

|