| If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany' frameset |

||||

|

Mainz

Army Depot |

||||

|

|

||||

|

||||

|

|

||||

|

||||

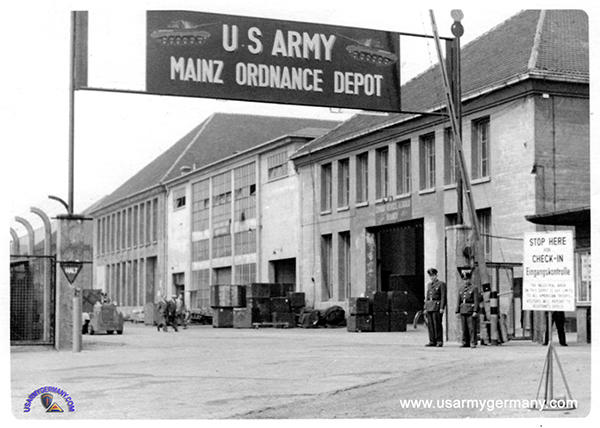

Main gate of Mainz Ordnance Depot, 1950s (Webmaster's collection) |

||||

|

||||

| Depot History | ||||

| 1954 | ||||

| (Source: STARS & STRIPES, April 11, 1954) | ||||

| The Mainz Ordnance Maintenance Depot ( The Depot began operation in September 1951. In the two and a half since then, the Depot has reclaimed about 300,000 ordnance items. The Depot is staffed by (?) Army officers, 46 enlisted men, 10 US Dept of the Army civilians and about 1,200 German technicians and laborers. In addition, Company B, 601st Ord Bn with three officers and 168 enlisted men is stationed at the depot. They are assigned in a training capacity. Depot CO is Col John W. Cave. The primary mission of the Mainz Depot is rebuild of tracked vehicles, artillery, fire-control equipment and small arms. If an item cannot be repaired by the depot, it is classified as "junk." Besides the ability to repair ordnance equipment, the Depot also has the capacity to manufacture certain items. Tank Rebuild -- the process is simple: transport the damaged tank to the depot from the field unit; take it apart; clean each section; give the chassis a steam bath; recondition any section that needs to be repaired; put the tank back together. Officials estimate it takes an average of 1,330 man-hours to rebuild a tank. The savings to the US government can be significant -- the pay scale of the foreign technicians is lower than in the US and there are no great costs in transportation compared to shipping the vehicles back to the US. |

||||

| 1956 | ||||

| (Source: STARS & STRIPES, March 17, 1956) | ||||

| Effective April 1, 1956, the Luther-Werke, based out of Braunschweig, Germany will take over the operation of the Mainz Ordnance Maintenance Depot in Mainz. Under a new contract recently negotiated between the German company and the US Army, the German company will become responsible for running the depot which employs 2,500 German workers. The current depot commander, Col John W. Cave, and his staff will only play a minor role in the operation of the depot. There will be no change in mission. The depot will continue to repair everything from a wristwatch to the giant 280-mm cannon for the US forces in Europe. |

||||

| If you have more

information on the history or organization of the Mainz Ord Depot,

please contact me |

||||

| (Source: Email from Bill Terry) | ||||

| In 1956 while assigned to Battery B, 264th FA Bn (280mm) in Bad Kreuznach, our gun, formerly known as Big Ike II, needed the trunnion bearings replaced. These are very large roller bearings that the gun tube is raised and lowered on. Four transporter drivers were required to stay with the gun until the job was finished, normally 2-3 days. The shop foreman liked American cigarettes so by providing him with several cartons we managed to drag out the repair for a week. At the end of the week the battery commander needed the gun back for us to prepare for battery tests at Baumholder. It was great TDY and we had to eat at the Wiesbaden Air Force Dining Facility, which was gourmet dining to us Army guys. While I was at Mainz Depot I got to ride with a driver testing an M4 Sherman tank on the test track in your picture. He insisted I wear a helmet. I'm glad he did because I have never before or since had a ride like that. |

||||

| 1975 | ||||

| (Source: STARS & STRIPES, March 10, 1975) | ||||

| The Mainz Maintenance Depot is commanded by Lt. Col Richard L. Bryant. Combat vehicles needing depot-level maintenance are brought to the Mainz Maintenance Plant for a complete overhaul. Following an inspection by employees of Luther Werke, the German contractor which performs the maintenance, the vehicles are completely disassembled, "We strip them right down to the frame, or hull as we call it, and rebuild and reassemble the vehicle," said Capt. Charles D. Couch, executive officer.

The depot is the only operating maintenance plant in Europe. The depot is expanding with the closure of the plants in Schwaebisch Gmuend and Boebllngen, Germany. "We are also the supply point for all engines and transmissions for combat vehicles of the Seventh Army," Couch added. The Mainz plant keeps more than 21,000 different parts in stock and more than $1 million a month is spent on repair parts. The plant also re-works the Army's "deuce-and-a-half" and five-ton trucks. Over 2,000 people are employed at the plant making it the second or third biggest industrial employer in Mainz." About 800 combat vehicles are recycled a year, with 80 to 100 units in the shops at any one time, according to the ordnance men. Last year, eight types of combat vehicles were handled at the plant and this year Mainz will perform work on 16 types. 'We used to rebuild three types of engines and now we are rebuilding 12 and also we were overhauling arid repairing three makes of transmissions and this year that figure has expanded to six," noted Bryant. Spread over 52 acres, the complex includes a test track. Following refurbishment, all combat vehicles spend two hours or 20 miles, whichever comes first, on the track where test drivers check out steering, suspension, braking, road speed, and swim and float capability for those vehicles that require it. According to LTC Bryant, the six major buildings of the plant complex were built by the French in 1921. The area was in the, French Zone following both World Wars. |

||||

| 1985 | ||||

| (Source: "The Role of Civilians in Maintaining Military Equipment, Vol. II," by Joseph R. Wilk, Eugene A. Narragon & Brian E. Mansir, Dec 1985) | ||||

| The Army makes extensive use of civilian mechanics to maintain weapon systems and equipment in the European Theater. It uses several categories of civilians (DAC, foreign national, CSU, contractor, and host nation personnel) to provide a wide range of maintenance services (technical advice, direct maintenance, and maintenance of WRM 1) and POMCUS 2) equipment). CONTRACT MAINTENANCE Contract maintenance, like technical assistance and direct maintenance, is a major category of the Army's use of civilians for maintenance in Europe. In this section (of the report), contract maintenance is describeed in three parts: Government-owned, contractor operated (GOCO) facilities, TARP contracts and specific equipment contracts. GOCO FACILITIES The Army has two major GOCO maintenance facilities in Europe, the Mainz Army Depot (MZAD) and the Area Maintenance Support Facility in Mannheim. MAINZ ARMY DEPOT The MZAD reports to AMC's Depot Systems Command but is under the operational command of AMC-Europe. Its primary mission is to provide depot-level maintenance support to USAREUR for combat and technical vehicles, missile systems, communications-electronics equipment, and other selected items. MZAD also provides backup GS maintenance and is a major participant in TARP. Additionally, MZAD provides technical assistance for maintenance and supply, and receives, stores, and issues new tactical vehicles that are fielded in Europe. MZAD's staffing includes US military personnel, DACs, foreign nationals, and contractor employees. The military personnel are primarily employed in supervisory and staff positions, while the DACs are used in a variety of roles. The foreign nationals perform mostly administrative and support tasks, while contractor employees perform most of the maintenance. The primary contractor is Mainz Instandsetzungsbetriebe GmbH, commonly referred to as Mainz Industries Panzerwerk (MIP). MIP operates several MZAD facilities: |

||||

| Other facilities that come under the purview of MZAD are: | ||||

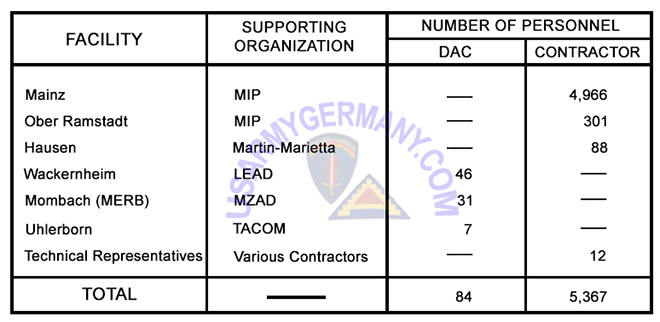

| The Army provides approximately 200 personnel (i.e. 78 military, 30 DACs, and 93 foreign nationals) to administer the contract and perform other supervisory, administrative, and support functions at MZAD. The maintenance functions are performed by several contractors and some DACs. As Table 2-12 shows, 5,367 contractor civilians are directly involved in MZAD's maintenance mission and of that number MIP provides 98 percent. At the Wackernheim, Mombach, and Uhlerborn facilities, 84 DACs are employed. MZAD is the only organization in Europe where an appreciable number of DACs perform hands-on maintenance. |

||||

Table 2-12. Civilian Staffing at Mainz Army Depot |

||||

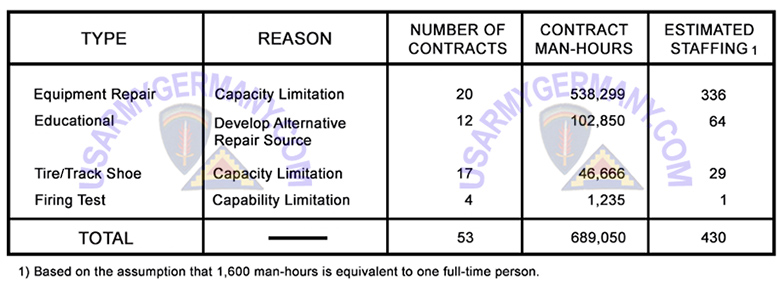

| MZAD makes extensive use of subcontractors to augment its production. In some cases, subcontractor support is needed because of capacity limitations (e.g., insufficient number of test stands). In other cases, subcontractor support is needed because of capability limitations (i.e., MZAD has no firing range to perform certain weapon tests). In still other cases, subcontractors have been awarded for educational purposes, that is, to develop alternative repair sources. In March 1985, MZAD had 53 subcontracts in effect. Those subcontracts are summarized in Table 2-13, which also shows the contracted man-hours and estimated contractor staffing. These subcontracts provide for 689,050 man-hours of production, the equivalent of 430 full-time personnel. Slightly more than 75 percent of the contract man-hours are devoted to the "Equipment Repair" category. |

||||

Table 2-13. FY85 MZAD Subcontracts |

||||

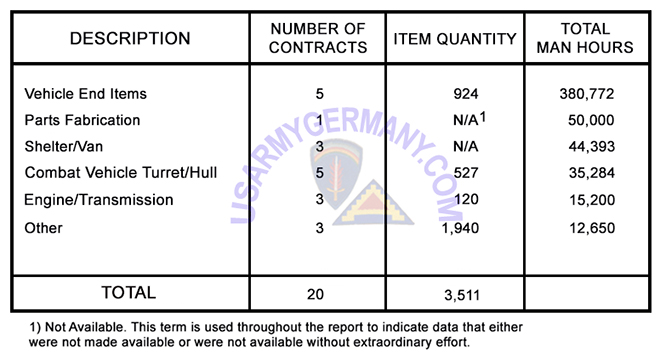

| The "Equipment Repair" and "Educational" type subcontracts bear further examination: the former because of its scope and the latter because of its objective. The "Equipment Repair" subcontracts provide 538,299 man-hours of production because of capacity limitations. These hours are spread over 20 contracts covering more than 3,500 items. The equipment supported under these subcontracts range from vehicle end items to engines and transmissions. Table 2-14 shows that the 924 vehicle end items require 380,772 man-hours, or slightly more than 70 percent of the total man-hours. Each of the other item categories requires less than 10 percent of the man-hours. |

||||

Table 2-14. MZAD FY85 Equipment Repair Subcontracts |

||||

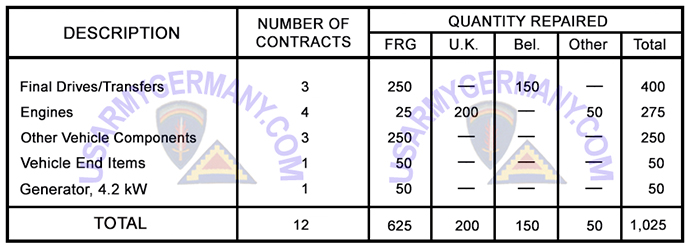

Table 2-15. MZAD FY85 Educational Repair Subcontracts |

||||

|

|

||||

| MIP Mainz Industries Panzerwerke - German Wikipedia Page covers some of the history of the Mainz Ordnance Depot starting with 1951 | ||||