| If you do NOT see the Table of Contents frame to the left of this page, then Click here to open 'USArmyGermany' frameset |

||||||||||||||||||

|

Defense Logistics Agency-Europe |

||||||||||||||||||

|

|

||||||||||||||||||

|

||||||||||||||||||

|

|

||||||||||||||||||

| Defense Logistics Agency in Europe | ||||||||||||||||||

| 1972 | ||||||||||||||||||

| (Source: Defense Logistics Agency) | ||||||||||||||||||

| The Defense Logistics Agency's responsibilities extended overseas when it assumed responsibility for defense overseas property disposal operations and worldwide procurement, management, and distribution of coal and bulk petroleum products in 1972, and worldwide management of food items for troop feeding and in support of commissaries in 1973. | ||||||||||||||||||

| Defense Fuel Region Europe | ||||||||||||||||||

| 1977 | ||||||||||||||||||

| (Source: STARS & STRIPES, Aug 28, 1977) | ||||||||||||||||||

| Headquarters of the Defense Fuel Region Europe is in Stuttgart and the commanding officer is Col Robert R. White. | ||||||||||||||||||

| 1979 | ||||||||||||||||||

| (Source: Letter to GEN Frederick J. Kroesen, CINCUSAREUR, from the European Branch of the US GAO, International Div, dated Sept 14 1979) | ||||||||||||||||||

| Webmaster's note: Following extract includes comments related to a GAO audit of Army management controls over bulk fuel in Germany and Italy. BACKGROUND USAREUR activities in Germany receive bulk fuel --motor gasoline, diesel fuel and jet propulsxon fuel -- through a system of US and NATO pipelines and storage terminals. The fuel, which is procured by the Defense Fuel Supply Center, is delivered by Military Sealift Command tankers to the US-owned, French-operated petroleum terminal located near Donges, France. From there the fuel moves by pipeline across France to one of Fuel Region-Europe three tank farms (Hinterweidenthal, Bellheim and Huttenheim) located in West Germany. Fuel stored at these activities is transported to the 22 supply points by railcar, barge, or truck. In fiscal year 1978, the three tank farms issued 76 million gallons of fuel -- 27 million gallons of motor gasoline, 35 million gallons of diesel fuel, and 14 million gallons of Jet propulsion fuel -- to the 22 supply points. In Italy, activities of the U S Army Southern European Task Force -- a USAREUR component command -- obtain motor gasoline and jet propulsion fuel through the NATO Italian Plpeline System. These fuels are delivered by Military Sealift Command tankers to the pipeline terminal at La Spezla, Italy, and are pipelined to storage terminals at Verona and Collecchio, Italy. From these terminals the fuels are transported by railcar or truck to the Military Community Activity at Vicenza, Italy, or the Leghorn Army Supply Depot at Livorno, Italy. In fiscal year 1978 Vicenza and Leghorn were issued about 535,000 gallons of motor gasoline and 150,000 gallons of jet propulsion fuel. Diesel fuel totalling about 280,000 gallons during fiscal year 1978 was procured by local contract and delivered by commercial transport to Vlcenza and Leghorn. |

||||||||||||||||||

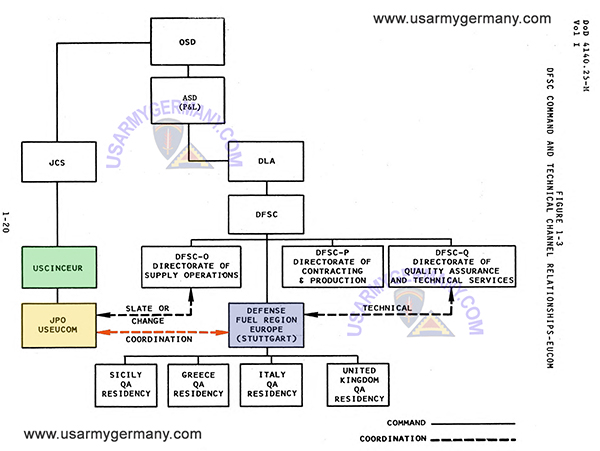

DFSC command and technical channel relationships with HQ USEUCOM, 1988 |

||||||||||||||||||

|

||||||||||||||||||

| 1988 | ||||||||||||||||||

| (Source: Management of Bulk Petroleum Products, Storage, and Distribution Facilities Manual, DoD 4140.25-M, July 1988) | ||||||||||||||||||

Defense Fuel Region-Europe (DFR-E), Patch Barracks, Stuttgart, APO 09128

|

||||||||||||||||||

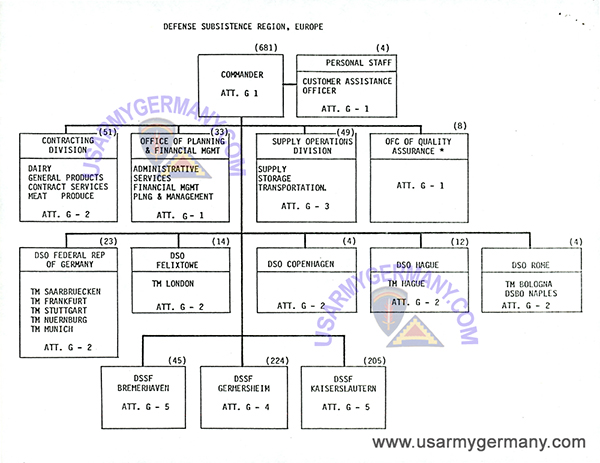

| Defense Subsistence Region Europe | ||||||||||||||||||

| 1982 | ||||||||||||||||||

| (Source: Department of the Army Historical Summary, FY 1982) | ||||||||||||||||||

| A memorandum of understanding (MOU) which transferred the troop issue subsistence supply mission from the 200th Theater Army Materiel Management Center (TAMMC) to the Defense Subsistence Region-Europe (DSR-E), a Defense Logistics Agency (DLA) activity, became effective 1 October 1982 and provided several advantages: |

||||||||||||||||||

| 1985 | ||||||||||||||||||

| (Source: Army Heritage and Education Center (AHEC), Carlisle, Pa.) | ||||||||||||||||||

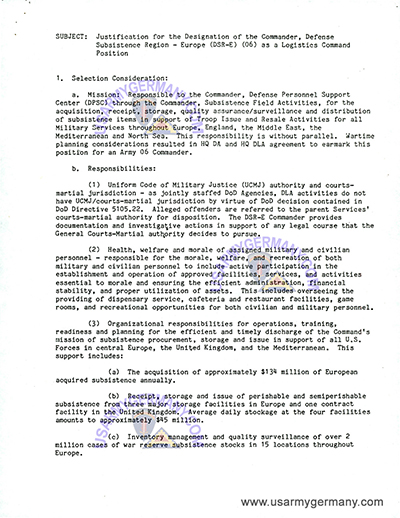

| In January 1986, Lt Gen Donald M. Babers, Director of the Defense Logistics Agency (1984-1986), submitted a request to Gen Richard H. Thompson, CG, US Army Materiel Command, for designation of the Commander, Defense Subsistence Region, Europe as a Logistics Command Position. | ||||||||||||||||||

| 1988 | ||||||||||||||||||

| Defense Subsistence Region Europe Extract from an article by Sp4 Charles Powers and Monika Kropf, ZWEIBRÜCKEN SUN, March 15, 1988 |

||||||||||||||||||

| "The bottom line is," according to Col. John F. Wright, Commander,

DSRE, "our one purpose for existing is to serve our customers." The customers of this Department of Defense organization include soldiers, sailors, airmen and civilians authorized to receive subsistance support. DSRE accomplishes it by "receiving, storing and issuing goods procured in the States as well as perishable products procured in Euroke," said Wright. "We act as wholesalers that sell to commissary and troop issue subsistance activities," he said, including some navy stores and navy vessels. We regularly supply 123 stores. 63 troop issue activities, and navy vessels as required." "Our territory includes Continental Europe, the United Kingdom as well as to a limited extent Saudi Arabia, Turkey, Greece and the Azores. Our operations are conducted through four subsistance ddenots - one in the United Kingdom and three here in Germany." According to Wright, a $650 million inventory of goods procured in the States comes through the four facilities annually. In addition, DSRE is responsible for a $220 million European procurement program. "We are oriented towards "buy America", he said, "but perishables such as diary, meat, fruit and vegetable products - as well as uniquely European items - must be procured locally." "We do not necessarily contract for the absolutely cheapest items available," Wright said, "because we also strive to obtain the most quality for the best price. Contracting is done on a competitive basis and we are not above playing one vendor off against another." "One of our top priorities is to buy the freshest items possible. To do this we are buying more often products in local markets. Over the past seven years, fresh fruits and vegetables obtained locally have increased by 34 percent while State-side acquisition has decreased 49 percent," Wright said. |

||||||||||||||||||

| 1990 | ||||||||||||||||||

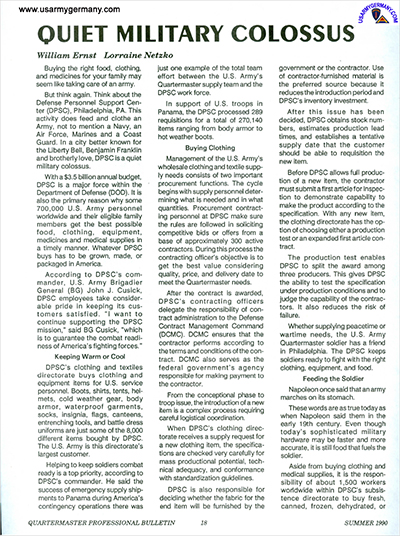

| (Source: Quartermaster Professional Bulletin, Summer 1990) | ||||||||||||||||||

| Article provides an overview of the role of the Defense Personnel Support Center in Philadelphia, PA and its subordinate element, the Defense Subsistence Region Europe, in Zweibrücken, Germany. | ||||||||||||||||||

| Cold Stores | ||||||||||||||||||

| Kaiserslautern Cold Stores | ||||||||||||||||||

|

||||||||||||||||||

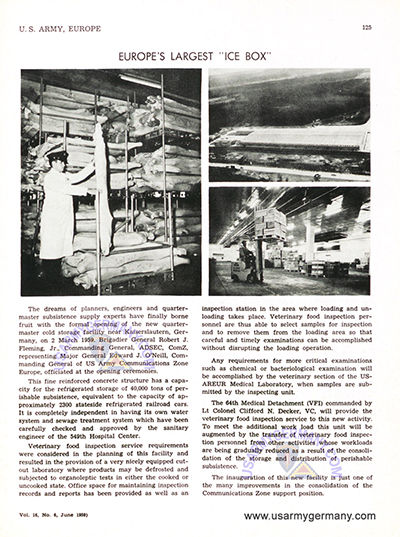

| 1959 | ||||||||||||||||||

| (Source: STARS & STRIPES, Feb 18, 1959) | ||||||||||||||||||

| The new $2 million cold-stores plant at Kaiserslautern, will go into operation on March 2.

The 18-acre supply complex was built by contractors under the direction of the U.S. Army Construction Agency for Germany. Construction was started in September 1957. The new plant is under the Com Z Quartermaster Supply Center, headed by Col Joseph S. Kujawski. CO of the Kaiserslautern operation is Maj William C. Lansford. A spokesman for the Com Z quartermaster supply center said the plant eventually will handle more than 60 per cent of all perishable foodstuffs in USAREUR. When the Kaiserslautern plant is fully operational — expected by June 30 — the cold-stores plants at Munich, Mannheim and Frankfurt "will be phased out, wholly or in part," the spokesman said. He said operations at the cold-stores plants at Paris and Bremerhaven, will not be affected. Centralizing operations in the modern, single-story plant will result in increased efficiency and economy because of the more efficient distribution pattern, it was explained. The new plant will provide 1.2 million cubic feet of storage space and has a capacity of more than 4,000 tons of chilled items and 10,000 tons of frozen items. This is about $10 million worth of stock, the spokesman said. The cold-stores building, which is 610 feet long and 226 feet wide, is divided into six rooms in which temperatures can be adjusted to handle either frozen or chilled foodstuffs. A railroad siding on one side of the plant will make it possible to handle 25 railroad refrigerator cars at one time. On the opposite side is a truck dock, where 30 refrigerator trucks or vans can be loaded or unloaded simultaneously. Com Z officials expect the plant to handle about 800 railroad cars and 575 trucks each month. The 18-acre supply complex was built by contractors under the direction of the • U.S. Army Construction Agency for Germany. Construction was started in September 1957. The new plant is under the Com Z quartermaster supply center, headed by Col Joseph S. Kujawski. CO of the Kaiserslautern operation is Maj William C. Lansford. The plant will be opened formally by Brig Gen Robert J. Fleming, Jr., CG of Com Z's Advance Section, in ceremonies at 2 pm March 2.) |

||||||||||||||||||

| 1968 | ||||||||||||||||||

| (Source: STARS & STRIPES, July 31, 1968) | ||||||||||||||||||

| The Kaiserslautern Cold Stores is a subordinate activity under the COMZ Supply and Maintenance Agency. The vast refrigeration complex is located outside of Kaiserslautern near the autobahn exit to Ramstein Air Base. The officer currently in charge of the Cold Stores is Maj J. L. Gagliardone. The complex has its own rail spur and is responsible for storing packaged frozen foods, ice cream and fresh edibles that are distributed to commissaries in Italy, Germany, Berlin, Belgium and The Netherlands. The Cold Stores began using SEAVAN containers in 1967 to improve transportation of sensitive items such as lettuce, celery, cheese, biscuits and packing potatoes. The SEAVAN is a refrigerated box 35 by 40 feet long with a capacity of 20 tons. It is loaded and then placed on a truck chassis which is pulled by truck to a designated seaport. There it is hoisted aboard a specially designed ship which carries only containers. Temperature in the vans aboard the vessel is controlled by an electrical system capable of holding a temperature to one degree of variation. Upon arrival at the port of Rotterdam, the container is offloaded, placed on another truck chassis and transported to the Cold Stores in Kaiserslautern. During the movement inland, the temperature of the container is controlled by gas bottles on the truck. More than 60 containers arrive at the Cold Stores each month. The food stores are checked daily by the 64th Veterinary Service Detachment, Vogelweh. Samples from 30,000 to 35,000 pounds of food are inspected every month. The 83rd Transportation Company, 53rd Trans Bn, at Kapuan Barracks, Vogelweh provides transportation support. Approximately 75 truck-vans can be loaded at one time. A crew headed by Arnold Seutter maintains the cooling system at the complex. There are a mile and a half of pipe lines inside the storage building and another 600 feet of piping in the machine house to carry the chilling ammonia-created gas. Temperatures in the various segments of the main building vary from deep freeze to merely cold, depending on the type of food stored. |

||||||||||||||||||

| 1974 | ||||||||||||||||||

| (Source: GAO Report (B-145455 February 1975) on delays in unloading Seavans at the Kaiserslautern Cold Stores.) | ||||||||||||||||||

| The KCS warehouse, constructed in 1959, was designed to store 440 short tons of refrigerated cargo. Since then the amount of goods to be stored there has expanded considerably, principally because of increases in the amount and number of items stocked. Presently the warehouse can unload 15 seavans a day. When the amount of goods to be unloaded exceeds the capability to unload and store them, the seavans must be detained in the KCS unloading yard, the German rail yards, or the ocean carrier port facilities. Depending on the type of transportation contract involved, ocean carriers allow 3 to 4 days for unloading the seavans without a penalty charge. Delays beyond that are chargeable at rates up to $60 a day. Requisitioning Procedure The United States Army Material Management Agency Europe (USAMMAE) consolidates requisitions from commissaries and troop supply activities and forwards them to Defense Personnel Support Center (DPSC) in Philadelphia. DPSC processes the orders to the depots and vendors in the continental United States and obtains movement instructions from the Eastern Area Military Traffic Management Command (EAMTMC). The Military Sealift Command (MSC) arranges for ocean transportation to Europe. USAREUR coordinates the movement of the vans to the final destination. A large backlog occurred in late 1973 and early 1974 when USAREUR requisitioned, and DPSC procured, excessive quantities of chicken. In the summer of 1973, USAREUR ordered very large quantities of chicken in anticipation of an increased demand due to high beef prices. In late summer 1974, USAREUR was told that the German Health Ministry would require certification, effective November 1, 1974, to restrict the import of frozen chicken. Again, USAREUR ordered large quantities of chicken. The German Government delayed implementation of the requirement, but the chicken shipments could not be stopped. Unless such large orders are coordinated through the entire system, KCS has an unmanageable workload and considerable seavan delay costs are incurred. Some temporary relief has become available with the leasing of commercial refrigerated storage space in Bremerhaven.Stores.) |

||||||||||||||||||

| 1984 | ||||||||||||||||||

| (Source: STARS & STRIPES, March 7, 1984) | ||||||||||||||||||

| The task of getting perishable food to commissaries fresh is the responsibility of the Defense Subsistence Storage Facility, Kaiserslautern, better known as the Kaiserslautern Cold Stores.

Maj. Dwight E. Phillips, chief of the facility, said the KCS is the largest cold-storage outlet in the world. Workers there oversee the receiving and shipping of about 10,000 tons of food each month. There are five freezer rooms at the facility, which are kept at minus 5 degrees Fahrenheit. The 87,500 square foot storage area is stacked, ceiling to floor, with all the frozen items sold in military commissaries in Europe. Next to the freezer rooms is the 23,620-square-foot chill room, which is arranged "like any refrigerator" to keep odors from different foods from affecting the taste of other chilled products. KCS is not a long-term storage facility, but a cooling point for items procured from U.S. and European vendors. Workers in the facility ship more than 600 different frozen and chilled items to 130 customers in 11 countries, some as far away as the Middle East. The operation supplies commissaries, troop issue points, embassies and allied forces, runs 24 hours a day, and processes 90,000 orders a month. In the past 25 years, KCS has had 3.5 million tons of perishable fresh food and 400,000 freezer trucks move through the facility. At any given time, there are about 650 different items and 43,000 tons of produce in stock. Current plans for upgrading the 25-year-old facility include a $5 million expansion project that will give the warehouse an additional 120,000 square feet of chill storage space. KCS was originally an Army element, but was redesignated in 1979 as a Defense Logistics Agency activity and functions now as a subordinate unit of the Defense Subsistence Region at nearby Zweibruecken. |

||||||||||||||||||

| 2009 | ||||||||||||||||||

| (Source: Article by 435th Air Base Wing/ Public Affairs / Published March 26, 2009 - accessed Aug 24, 2019) | ||||||||||||||||||

| RAMSTEIN AIR BASE, Germany -- This year marks Kaiserslautern Cold Storage's 50th anniversary serving commissaries and customers within the United States military European theater. The momentous anniversary was commemorated with a ceremony and reception, as well as guided tours of the state-of-the-art facility March 20. KCS stores frozen foods and goods to be distributed to and sold in commissaries throughout Europe. It is currently the primary cold storage facility for 42 commissaries spanning 10 countries and delivers to customers in more than 35 countries. It is located just outside of Ramstein Air Base's east gate and is conveniently connected to the public road system, the autobahn, and the German railways. The Defense Commissary Agency purchased the operation in 1997 and spent a considerable amount of money and man-hours streamlining operations, increasing items stocked, and upgrading the facility itself. "When DeCA took over KCS twelve years ago, it needed a lot of money and time to bring it up to standard. We invested in everything from new computers and warehousing systems to upgrades to the loading docks and transportation," Thomas E. Milks, DeCA Europe director said. KCS has nearly 150 employees, of which 90 percent are local nationals. Many of the DeCA team members have been employed at the KCS for several years and have been a part of the facility's evolution. Manfred Young, a 22 year employee of KCS, commented on one way in which his job had improved. "The storage grid for the items in the warehouse and the location of new items used to be only on paper and we had to go to the control office every time we had to move an item to get the location paperwork," he said. "Today everything is computerized and has replaced a lot of the unnecessary paperwork. We have headsets for communicating with the control office; we can call in location requests and get an answer immediately. This system saves a lot of time and allows us to keep working." And indeed the KCS team has worked diligently over the years, vastly contributing to the facility's success. "I regularly challenge the management and staff to find more ways to save costs and satisfy customers, and they deliver every time." said Mr. Milks. KCS is not only a vital part of the U.S. military community in Europe, but has become an economic asset to the local German community as well. "This anniversary means an extraordinary cooperation of numerous organizations. From purchasing, stock administration, to transport companies, drivers, mechanics, food inspectors, security personnel, engineers, constructors, computer specialists, technicians as well as administrators and managers of the different branches are all included in this process up to the delivery to the U.S. forces, the final customer," said Dr. Klaus Weichel, Lord Mayor of Kaiserslautern. "You can be assured that Kaiserslautern Cold Storage serves as an illustrious signboard to Kaiserslautern and the region. It is in any aspect a flagship organization and an impressive example of an utmost successfully managed American establishment." |

||||||||||||||||||

| Terminal Markets | ||||||||||||||||||

| 1984 | ||||||||||||||||||

| (Source: Army Logistician, April 1984) | ||||||||||||||||||

| How DSRE Procures Subsistence by Major Cheryl A. Crawford ) The mission of the Defense Subsistence Region Europe (DSRE) is to provide theater-wide subsistence support to commissaries and troop issue activities. The subsistence region manages three freeze storage facilities at Kaiserslautern and Bremerhaven, Germany, one freeze storage facility in Felixstowe, England, and one nonperishable facility at Germersheim, Germany. These facilities receive, store, and distribute subsistence items brought from the United States. The arm of DSRE responsible for procuring perishable food items is the Purchasing Division, the most geographically dispersed element of the region. While most procurements are made centrally from the Zweibruecken headquarters, the Purchasing Division operates field offices in Rome, Copenhagen, The Hague, and Alicante (Spain). By keeping abreast of changing economic or agricultural conditions that might influence offshore acquisition, these offices serve as DSRE's eyes and ears on the world market. They also perform crop surveys in their respective growing areas and conduct preaward inspections on prospective vendor plants. Eight terminal markets are also operated by DSRE. These markets purchase small quantities of highly perishable produce such as strawberries, grapes, egg plants, or exotic items like mangoes and pineapples. They also purchase seasonal vegetables like turnips, green beans, brussel sprouts, and peaches. Five markets are located in the German cities of Frankfurt, Nuernberg, Munich, Stuttgart, and Saarbruecken. The remaining three are located in Bologna, The Hague, and London. Most offshore procurements, regardless of commodity, are made centrally by the Zweibruecken office. This is the most efficient method for procuring large quantities of subsistence that can withstand transportation and handling. Perishable subsistence products valued at more than $137 million were bought from European sources in fiscal year 1982. |

||||||||||||||||||

| Related Links: |

||||||||||||||||||