| If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany' frameset |

||||||||||||||||

|

US

Army Materiel Command, Europe |

||||||||||||||||

|

|

||||||||||||||||

|

||||||||||||||||

|

|

||||||||||||||||

| MATCOMEUR History | ||||||||||||||||

Bldg 4000, Kreuzberg Kaserne, Zweibrücken (Pete Poulsen) |

||||||||||||||||

HQ USAMATCOMEUR, Kreuzberg Kaserne, Zweibrücken (Pete Poulsen) |

||||||||||||||||

| 1969-1972 | ||||||||||||||||

| (Source: USAMMAE Pam 10-5, unknown date -- probably mid-1970s) | ||||||||||||||||

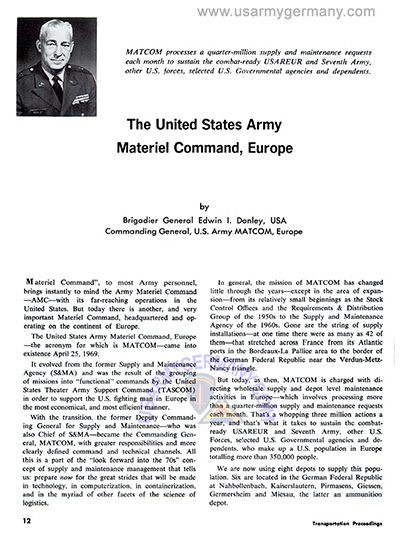

| HISTORICAL BACKGROUND Wholesale supply support to the United States Army, Europe has been provided on a continuous basis since World War II by one supply and maintenance type activity in Europe. This organization, changing periodically in title and structure during its twenty-nine year history, has fulfilled its dynamic mission. Through 1962, the supply and maintenance mission was accomplished by a collective group of eight technical services supply control agencies (SCA's), located mostly in France. During the next three years (1963 to 1965) the SCA's were merged into the U.S. Army Supply and Maintenance Agency (S&MA), which had its headquarters in Orleans, France. Its supply policy and financial management function, together with one automatic data processing facility (ADP) were located at Maison Forte, France, and its stock control activities, supported by a second ADP facility, were consolidated at Verdun, France. This new activity was also assigned responsibility for the supervision of depot level storage and maintenance missions of the United States Army Communications Zone, Europe, when Headquarters, 4th Logistical Command, located at Verdun, was deactivated. The complete supply and maintenance mission was then being performed by the S&MA with eight hundred fewer personnel than had been employed by its predecessor organizations. The dissolution of the eight SCA's, the formation of the S&MA, and the assumption of depot storage and maintenance missions were forward steps toward the goal to consolidate and automate. The consolidation resulted in great savings by reduction in facilities and personnel at no lose of efficiency. It permitted the closing of operating points in Poitiers and Ingrandes, France, and left those located at Orleans and Verdun, France, and at Giessen, Germany. The simultaneous acquisition of modern ADP equipment, timed to coincide with the consolidation plan, reduced considerably the manual work involved in processing ten thousand supply actions daily. In mid-1965, the S&MA commenced operating under the military standard requisitioning and issue procedures (MILSTRIP); during the latter part of the year the processing of requisitions for brand name resale subsistence items was relocated to Giessen, Germany. The following year saw more changes. The United States Industrial Center, Europe, located at Sandhofen, Germany was discontinued resulting in the saving of considerable manpower. The four major rebuild plants at Mainz, Boeblingen, Schwaebisch-Gmuend and Ober-Ramstadt, Germany, which were controlled by the United States Army Industrial Center, Europe, continued as independent activities, under the operational control of S&MA, assigned to United States Army Communications Zone, Europe. |

||||||||||||||||

The rail car-mounted MOBIDIC ADP system at Hochmülbach, near Zweibrücken (Mai-Nelson) (Please contact the webmaster if you have information on the MOBIDIC computer at Zweibrücken) |

||||||||||||||||

After the S&MA completed its move to Zweibruecken, Germany, further consolidations and management improvement actions highlighted the streamlining of operations. The Logistics Systems Management Office of the S&MA was activated to improve the data systems. The Depot Maintenance Division, which had moved from Maison Forte, France, to Munich, Germany in February 1967, was relocated to Zweibrwecken in 1968. In addition, during the latter half of 1968, ADP equipment and personnel (which had been temporarily relocated from Verdun and Maison Forte, France, and mounted on rail car equipment located at Hochmühlbach, 14 miles from Zweibruecken, Germany), was moved from the train site to the Kreuzberg Kaserne, high on a hill overlooking Zweibruecken. Shortly thereafter, in 1968, third generation ADP equipment was acquired, and programmers, were trained in common business oriented language (COBOL). In October 1968, a major policy change was adopted. This involved the management of major end items together with their related repair parts by systems managers rather than management by stock number. To implement this concept, the Equipment and Parts Division was dissolved and the Aviation and Electronics Division, the Automotive and Weapons Division and the Mobility Equipment Division established. Oct 25 April 1969, the S&MA was inactivated.and Headquarters, U.S. Army Materiel Command, Europe (MATCOM) was activated at Zweibruecken, Germany. The responsibilities of the new command were expanded on 1 July 1969 by Headquarters U.S. Theater Army Support Command, Europe (TASCOM), which assigned all TASCOM depots, maintenance plants, and other wholesale supply and maintenance activities to MATCOM. Soon after August 1970, the Permissive Action Link Detachment, the US Army Advanced Weapons Support Command and the US Army Aviation Maintenance Center, Sandhofen, were reassigned from MATCOM to TASCOM. Depot complexing actions aligned Nahbollenbach Army Depot under Kaiserslautern Army Depot; and Pirmasens Army Depot and Mannheim Depot Activity under Germersheim Army Depot. The Giessen Depot Activity was phased out and the BNR mission transferred to Nahbollenbach. (The historical background information continues with the inactivation of MATCOM in 1972 and the formation of the US Army Materiel Management Agency, Europe.) |

||||||||||||||||

| 1971 | ||||||||||||||||

(Source: STARS & STRIPES, Oct 24, 1971) |

||||||||||||||||

The US Army Materiel Command-Europe (MATCOM), headquartered in Kreuzberg Kaserne, Zweibrücken, has sites in Germany, Spain, Italy, Denmark, the Netherlands and England. In Germany, MATCOM operates: four maintenance plants, five Army depots and three special activities. Its mission is to provide wholesale supply support to the US Army in Europe. MATCOM supervises the depot level storage and maintenance missions of the Theater Army Support Command (TASCOM) - this includes operating all of TASCOM's depots, maintenance plants and other wholesale supply and maintenance activities. MATCOM has a strength of 16,000 personnel (over 2,500 at headquarters in Zweibrücken alone) - about one-fourth of them are military. CG of MATCOM is Brig Gen Harold B. Gibson, Jr. Recent improvements in the supply process through computerization and depot consolidations have resulted in better control of the more than $2 billion in inventories; improvement of delivery time up to 40 percent; a $5 million reduction of storage costs; and a decrease of operating stocks by $500 million. A new airlift service for high-priority items has been implemented using Chinook (CH-47) and Flying Crane (CH-54) helicopters - on a daily basis, a CH-47 (Schwäbisch Hall?) picks up supplies from the Pirmasens Army Depot and a CH-54 (Finthen AAF) flies to the Germersheim Army Depot. They deliver to Baumholder, Giessen, Fulda and Hanau. |

||||||||||||||||

| Additional issues of the MATCOM Ledger (1970-1972) are available on line on Dropbox. (These issues have been made available thanks to the efforts of several members of the "Zweibrücken and Kreuzberg Kaserne" Facebook Group). If you have additional copies of the MATCOM Ledger that are not yet in our online collection, we would be interested in hearing from you -- please contact the websmaster -- see email link at top of page -- or the FB Group. | ||||||||||||||||

| A new reorganization - formation of depot complexes to serve V Corps and VII Corps - is currently being implemented. Giessen Army Depot became an activity under Nahbollenbach Army Depot. Subsequently, Nahbollenbach has become a part of the Kaiserslautern Army Depot Complex. Concurrent with the above changes, Pirmasens Army Depot has become part of the Germersheim Army Depot Complex. One other depot operated by MATCOM is located in England (near Liverpool): Burtonwood Army Depot. Its warehouse is large enough to hold 95 football fields. Besides the usual supplies stored there, the depot is also responsible for the Marine Reserve Fleet (which used to be located in France before FRELOC) - this includes ocean-going landing craft and support vehicles. Each of the Germany-based depots also have their unique missions: Miesau Ammo Depot: is the Army's only ammunition depot on the continent of Europe. The depot is responsible for the storage, renovation, surveillance and modification and destruction of ammunition. Germersheim Army Depot: this depot serves as the primary storage site for tank and automotive equipment. There are two major storage areas - the Big O (nine warehouses arranged in the form of an "O") in the northeast corner of the depot and the Big E (eleven warehouses that form a large "E") in the northwest corner. Pirmasens Army Depot: the depot serves as MATCOM's electronic, air and industrial supply storage area. In addition to these supplies, the depot includes over 7,000 tons of C-rations (subsistence) that are stored in caves built by the German Wehrmacht before WWII. Another special mission includes the Calibration Test & Measurement Equipment Center. Nahbollenbach Army Depot: primary mission is to store and ship Class I (troop issue) food items used in dining halls and commissaries. A special responsibility includes a parachute repair facility. Kaiserslautern Army Depot: this is the largest depot in USAREUR - 143,000 tons of supplies are stored here. Eighty percent of the supplies fall into one of two categories: ground support equipment and tactical vehicle parts. The remaining twenty percent include bridging, pipeline and railroad equipment and supplies. Maintenance Plants: two (Mainz and Böblingen) of the four plants are GOCO (government-owned, contractor-operated); the other two (Schwäbisch-Gmünd and Ober-Ramstadt) are government owned and operated.

Two special activities of MATCOM: Petroleum Directorate: this activity handles bulk petroleum for the Theater, storing approximately 8.5 million barrels in its system of pipelines and tank farms. The activity also controls the NATO Pipeline System which has over 450 miles of pipelines and 17 tank farms. . Subsistence Field Activity: this activity is responsible for the in-theater procurement of food items with a value of over $80 million annually. It also provides cold storage services for mess halls and commissaries throughout Europe. MATCOM Headquarters has the largest military computer system in Europe to help it keep track of the millions of tons of supplies and almost 250,000 requisitions a month. |

||||||||||||||||

|

|

||||||||||||||||

|

Related Links:

|

||||||||||||||||